Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Well managing to get some progress , made sure all the gibs where nipped up , I just fully locked the compound slide as recommended by hood before as was not using it so try and take play out of the equation. I also ran it at a speed far away from the resonance to try and cut down on the vibrations. New tooltip because I was too ham-fisted with the tool post and smacked the insert into tailstock but never mind new cutting point on insert took any dullness out the equation.

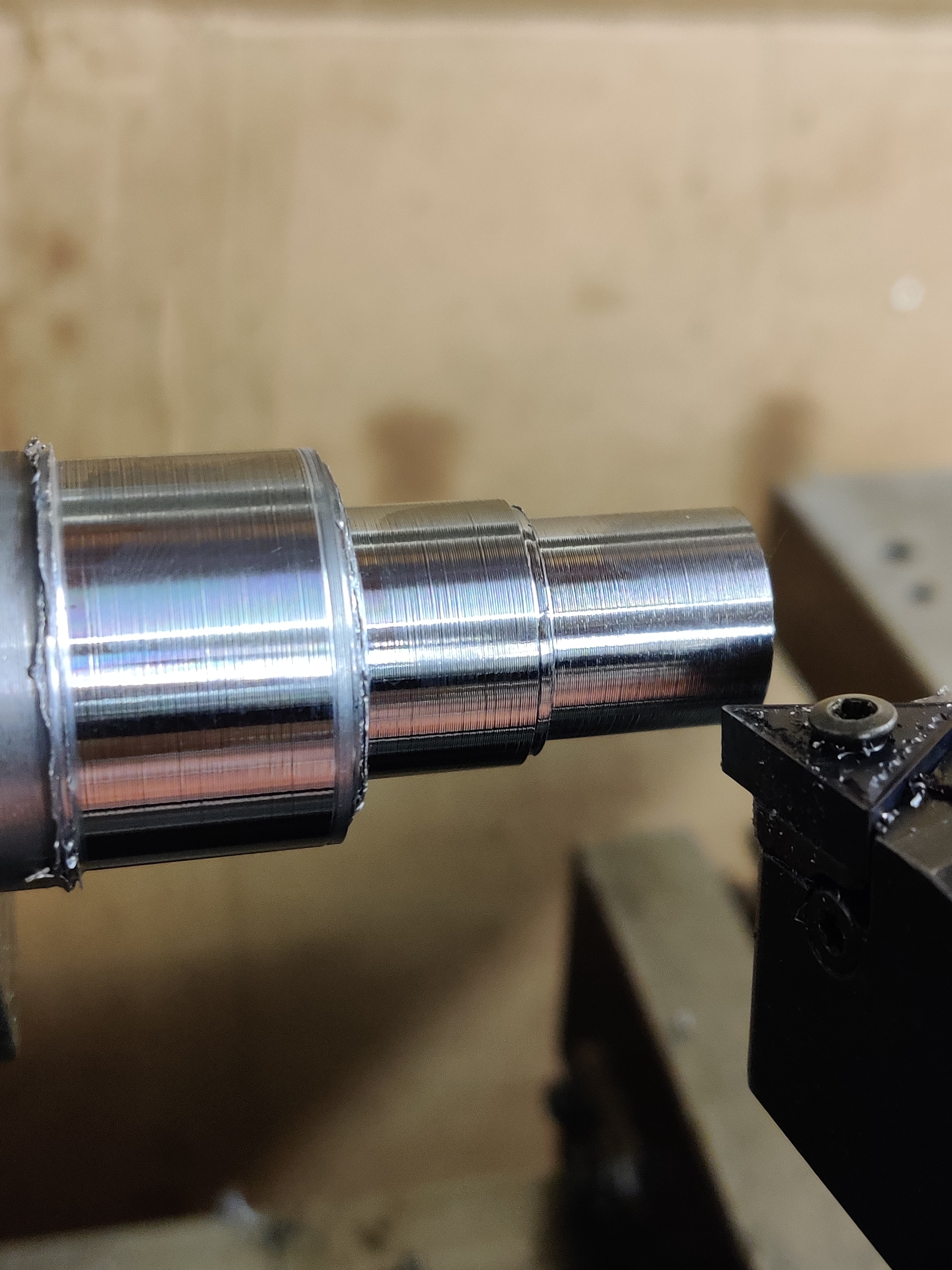

1200RPM , 5 Thou per rev feed and 0.8 DOC on a 04 radius TNMG from kennemetal.

Now I say it the photo shows up the feed marks more so than by eye but they are a lot less apparent than they where before and can just be picked up by fingernail where as before it was like rubbing your nail on a file as the grooves where deeper.

Now the next part with turning like this taking heavy DOC working out how the spring in the part works as I see if you go in say 0.5mm DOC then go backwards it cuts more so I assume this is the spring somewhere and makes it more difficult to get to a final measurement compared to light cuts.

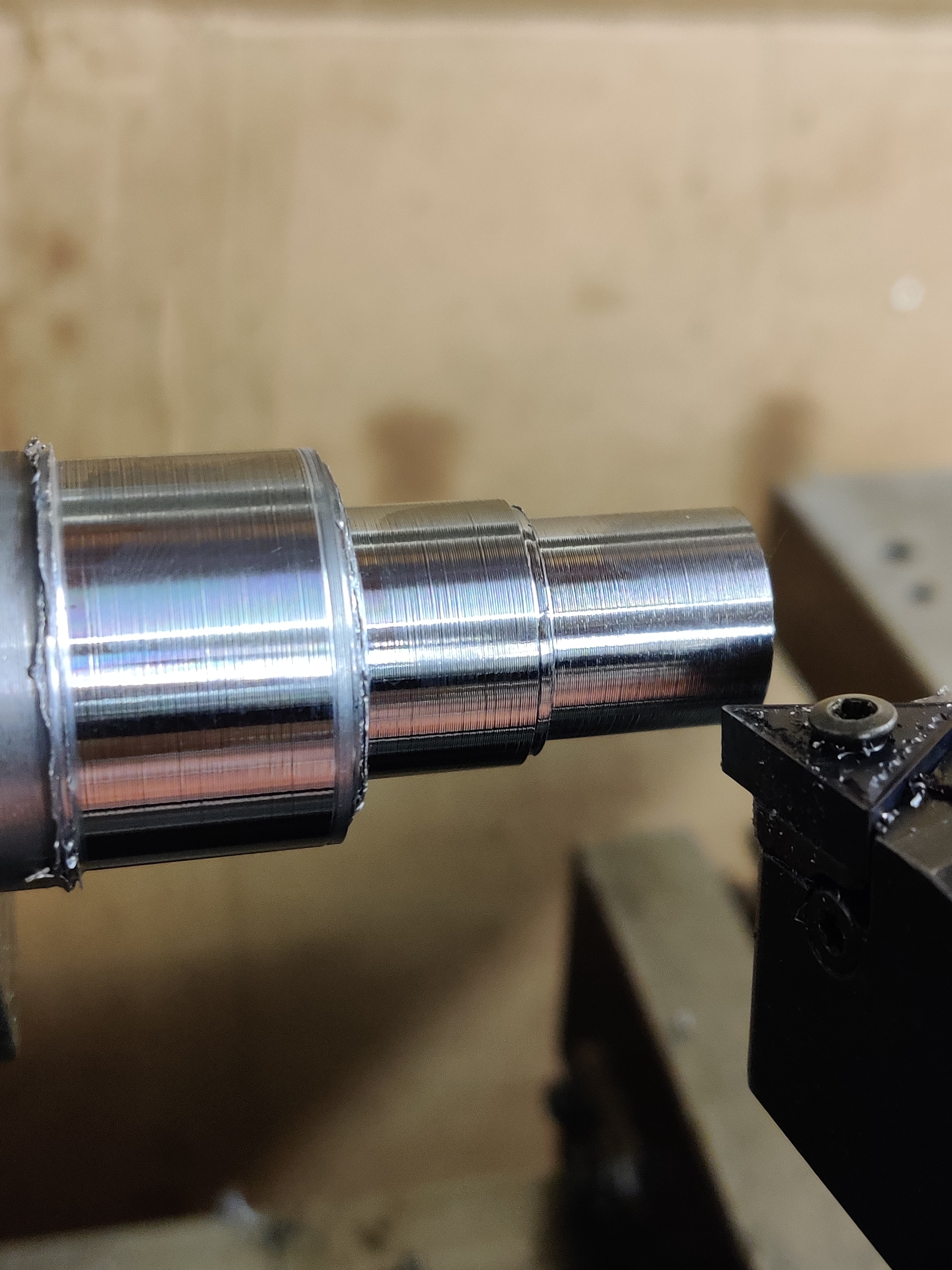

And here is how bad the lines where before

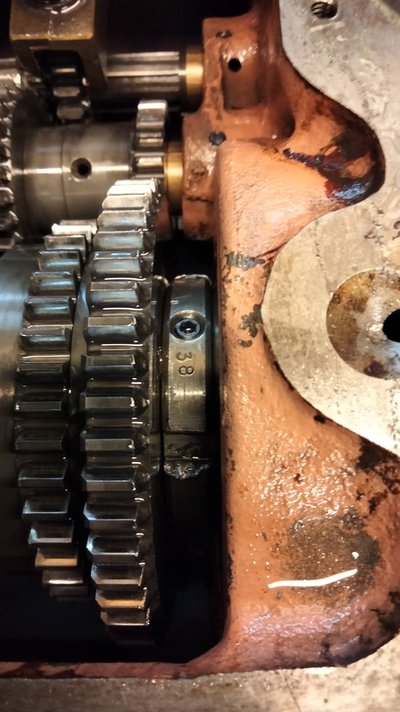

Then with the lowest feed at 1200RPM using the ultra sharp ally inserts it gave a nice finish which seems to be alot more uniform than what I have been getting previously not a mirror but a very very smooth finish with uniform lines and reflections so happy with that. Will be very handy if holding tight tolerences as can shave off a few thou per cut happily and leave a good finish.

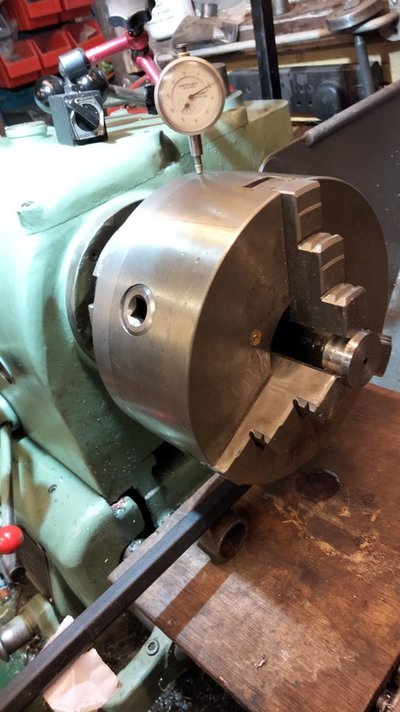

Also had a go with the proper technique I hope for checking the spindle bearings , Seems about 0.02mm of play up and down with force on a pry bar pushing up. Will need to remember to try when it is warm

Unfortnatley not sure what exact measurement I am looking for here as do not think it was published by colchester in the manual but it seems reasonable to me.

Now doing this I was using the tailstock a little aswell and forgot that I had aligned the headstock so will need to align the tailstock now as it would not sit right inparts and was being pulled , The manual calls for a ground test bar which I dont have so thinking of using the simmilar method to headstock alignment turning a test bar and using mics on it untill all taper is removed then I know it is running true and not pulling the part to either side.

Photo didnt really work but by eye it was clearly not aligned

Again thanks for the help everyone , Still got a few things to try with HSS and other suggestions

1200RPM , 5 Thou per rev feed and 0.8 DOC on a 04 radius TNMG from kennemetal.

Now I say it the photo shows up the feed marks more so than by eye but they are a lot less apparent than they where before and can just be picked up by fingernail where as before it was like rubbing your nail on a file as the grooves where deeper.

Now the next part with turning like this taking heavy DOC working out how the spring in the part works as I see if you go in say 0.5mm DOC then go backwards it cuts more so I assume this is the spring somewhere and makes it more difficult to get to a final measurement compared to light cuts.

And here is how bad the lines where before

Then with the lowest feed at 1200RPM using the ultra sharp ally inserts it gave a nice finish which seems to be alot more uniform than what I have been getting previously not a mirror but a very very smooth finish with uniform lines and reflections so happy with that. Will be very handy if holding tight tolerences as can shave off a few thou per cut happily and leave a good finish.

Also had a go with the proper technique I hope for checking the spindle bearings , Seems about 0.02mm of play up and down with force on a pry bar pushing up. Will need to remember to try when it is warm

Unfortnatley not sure what exact measurement I am looking for here as do not think it was published by colchester in the manual but it seems reasonable to me.

Now doing this I was using the tailstock a little aswell and forgot that I had aligned the headstock so will need to align the tailstock now as it would not sit right inparts and was being pulled , The manual calls for a ground test bar which I dont have so thinking of using the simmilar method to headstock alignment turning a test bar and using mics on it untill all taper is removed then I know it is running true and not pulling the part to either side.

Photo didnt really work but by eye it was clearly not aligned

Again thanks for the help everyone , Still got a few things to try with HSS and other suggestions

The carriage can be clamped to eliminate it during crossfeeding. But not the answer?

The carriage can be clamped to eliminate it during crossfeeding. But not the answer?