Good grief man, your in Lower Darwen aren’t you?

Nip up Milking lane and see me.

Im in Leyland Adrian, probably only about 15-20 mins away from you. Next time I'm over your way I'll call by. PM your phone number sometime plz.

Good grief man, your in Lower Darwen aren’t you?

Nip up Milking lane and see me.

I've got a question which relates so I hope you don't mind a mini hijack. It will save another thread on a similar question.

I have a keyway to cut in a piece of 17mm bright bar. The key is about 20 to 25mm long and 4.7 x 5mm. I'll check again but I'm pretty sure it's the 5mm dimension that's the width so a 5mm cutter I'll use.

First of centring the cut. A chap up the road has a really old milling machine he has said I can use, it has no dro and the dials are pretty rusted over. How do I find the centre avoiding the backlash? Could I use a magnetic dial indicator?

Then levelling the work piece in the vice. I'm not sure I'd feel happy adjusting the bed on somebody else's machine or even know what nuts and bolts to try. I'm hoping a dial indicator again stuck to the head or something solid nearby I can adjust the piece in the vice.

And finally, which cutter should I use, a slot drill or end mill. The depth is half of 4.7mm and again I'll have no easy way of working out depth of cut.

Any advice greatly appreciated.

And finally, which cutter should I use, a slot drill or end mill. The depth is half of 4.7mm and again I'll have no easy way of working out depth of cut.

traditionally a slot drill had two flutes and the cutting edges join at the centre so they can be be plunged into the metal and cut a flat bottomed hole.

Not quite accurate, the cutting lips are asymmetric with the longer one crossing through the centre point. If not you'd still have a dead area.

It's a vertical mill, the keyway is for a woodruff key into the end of the axle.

If you've seen my project thread, it's a 17mm bright steel axle with a keyway for a mobility scooter wheel.

I'll take a look at those videos when I get an hour. Cheers

oh nearly forgot would love to see photos of your build

.

.

@gaz1 photo's for ya. A very simple build copied from one of your videos.

View attachment 115009

Piece of 50 x 50mm angle with a flat piece of 15mm thick to go in the toolpost welded on the edge of the angle, couple of bits of flat tacked on the ends of the angle to support g clamps.

View attachment 115010

Centred by pressing the 2 pieces together with the cross slide on a shaft between the chuck and tailstock, then tack welded while in position in the lathe. (dont have a photo of this).

View attachment 115011

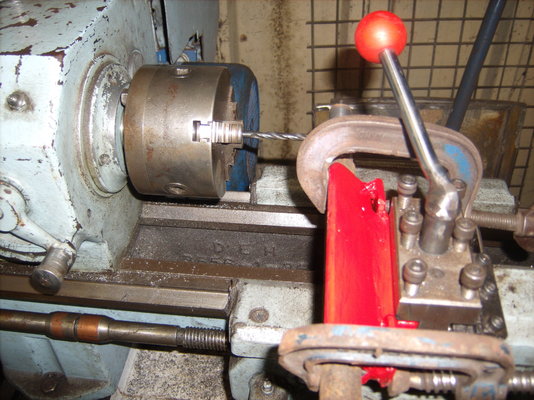

Shaft clamped in the attachment and drill bit in the lathe chuck.

View attachment 115012

Ready to drill hole through shaft. I don't have any milling cutters yet.

View attachment 115013

I can imagine the g clamps being in the way at times, could maybe support with smaller angle facing other angle and strong hose clips.

View attachment 115014 .

6mm dia drill bit.

View attachment 115015

That's good enough for me. Thank you for the vids and suggestion in the first place.

I've got a question which relates so I hope you don't mind a mini hijack. It will save another thread on a similar question.

I have a keyway to cut in a piece of 17mm bright bar. The key is about 20 to 25mm long and 4.7 x 5mm. I'll check again but I'm pretty sure it's the 5mm dimension that's the width so a 5mm cutter I'll use.

First of centring the cut. A chap up the road has a really old milling machine he has said I can use, it has no dro and the dials are pretty rusted over. How do I find the centre avoiding the backlash? Could I use a magnetic dial indicator?

Then levelling the work piece in the vice. I'm not sure I'd feel happy adjusting the bed on somebody else's machine or even know what nuts and bolts to try. I'm hoping a dial indicator again stuck to the head or something solid nearby I can adjust the piece in the vice.

And finally, which cutter should I use, a slot drill or end mill. The depth is half of 4.7mm and again I'll have no easy way of working out depth of cut.

Any advice greatly appreciated.

Nice work, but your right milling is boring in a lathe or on a mill. Ive bisshed up a few things with not quite focusing on what im doing as i was boredDecided to try my luck at making a 4 way tool post from a piece of 50mm thick ms, bought a 12mm milling cutter and after many cuts it's taking shape. Could do with some boredom relief tablets but it's a spare time job.

View attachment 117496

View attachment 117497