Canpoo

New Member

- Messages

- 15

- Location

- Portugal

Hey there,

So I've been welding for a total of 2 days ... i know, i know, master welder.

... i know, i know, master welder.

First off, some info regarding equipment:

WELDER:

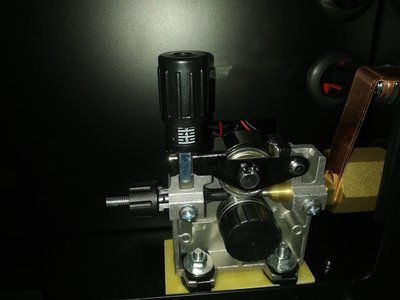

Rohr mig-200mi. (pictures attached)

Sealey MIG/7K06 Mild Steel MIG Wire 0.7kg 0.6mm A18 Grade

https://www.amazon.co.uk/gp/product/B000RA10G6/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

GAS:

Straight CO2

I've never welded before, so my knowledge comes from this forum (really appreciated) as well as YouTube.

On my first go at it, I was quite jumpy due to a healthy mix of excitement and caution. Fortunately i did record the moment so that I could be made a fool of :

:

https://photos.app.goo.gl/AyvjDC8ZPXmVzYWQ9

After a few minutes, there was no stopping this bead runner and I was finally able to try and apply the techniques I recently acquired on the internet. Everything from gas regulation, to volts and wire speed, gun angle and push or pull techniques... all within a 20 minute timeframe It was really an interesting experience that sparked (

It was really an interesting experience that sparked ( ) my interest in welding:

) my interest in welding:

https://photos.app.goo.gl/jM9wAADiJbJ2T4VHA

This past 2 days I've been practising beads on 2mm plates with a push technique trying to make those eeeeee's (not sure what the name is).

This is the result of my first day of welding:

https://photos.app.goo.gl/rUwTKf3S6HxWsJ8W9

and my second day of welding:

https://photos.app.goo.gl/PGesSwDj4gxiQWn59

I'm running 15 cfh of straight CO2, and trying different approaches to voltage and wire. But I tend to keep the volts on level 5/6 and wire speed at about the same. I know this doesn't say much my voltage levels only show when the gun is "hot" so i'm not yet confident enought to glance at the machine while welding.

HELP

Please do critique my beads and let me know how I can improve. I find that my beads are too tall and I don't know why. I seem to be getting penetration as I can see a silhouette of the bead on the underside. Maybe i'm travelling to slow or have a higher wire speed than necessary?

Thank you all and let me know what you think of my progress,

Diogo

So I've been welding for a total of 2 days

... i know, i know, master welder.

... i know, i know, master welder.First off, some info regarding equipment:

WELDER:

Rohr mig-200mi. (pictures attached)

- Runs off a Standard UK Plug 240V AC

- Input Current 28a

- Output Currents: MIG 50a - 200a, MMA 20a - 200a

- Duty Cycle 60%, Transfer Efficiency over 85%

- Frequency 50Hz - 60Hz, Power Factor 0.93

- Plastic Spool with Metal Bar

- Insulation Grade F / Housing Protection Grade IP21

- Wire Specs: Speed (m/min) 2.5-13, Gauge 0.6mm - 1.0mm, Max Weight 5KG

Sealey MIG/7K06 Mild Steel MIG Wire 0.7kg 0.6mm A18 Grade

https://www.amazon.co.uk/gp/product/B000RA10G6/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

GAS:

Straight CO2

I've never welded before, so my knowledge comes from this forum (really appreciated) as well as YouTube.

On my first go at it, I was quite jumpy due to a healthy mix of excitement and caution. Fortunately i did record the moment so that I could be made a fool of

:

:https://photos.app.goo.gl/AyvjDC8ZPXmVzYWQ9

After a few minutes, there was no stopping this bead runner and I was finally able to try and apply the techniques I recently acquired on the internet. Everything from gas regulation, to volts and wire speed, gun angle and push or pull techniques... all within a 20 minute timeframe

It was really an interesting experience that sparked (

It was really an interesting experience that sparked ( ) my interest in welding:

) my interest in welding:https://photos.app.goo.gl/jM9wAADiJbJ2T4VHA

This past 2 days I've been practising beads on 2mm plates with a push technique trying to make those eeeeee's (not sure what the name is).

This is the result of my first day of welding:

https://photos.app.goo.gl/rUwTKf3S6HxWsJ8W9

and my second day of welding:

https://photos.app.goo.gl/PGesSwDj4gxiQWn59

I'm running 15 cfh of straight CO2, and trying different approaches to voltage and wire. But I tend to keep the volts on level 5/6 and wire speed at about the same. I know this doesn't say much my voltage levels only show when the gun is "hot" so i'm not yet confident enought to glance at the machine while welding.

HELP

Please do critique my beads and let me know how I can improve. I find that my beads are too tall and I don't know why. I seem to be getting penetration as I can see a silhouette of the bead on the underside. Maybe i'm travelling to slow or have a higher wire speed than necessary?

Thank you all and let me know what you think of my progress,

Diogo

-

205106-c2d8d406a15557f2b090ee8f6883dd14.jpg41.1 KB · Views: 52

205106-c2d8d406a15557f2b090ee8f6883dd14.jpg41.1 KB · Views: 52 -

205104-f4e09f5f507b9cafebd0b68f3801bdda.jpg19.2 KB · Views: 64

205104-f4e09f5f507b9cafebd0b68f3801bdda.jpg19.2 KB · Views: 64 -

205103-6a8ffab09fe2861297df1e0be265818c.jpg17 KB · Views: 54

205103-6a8ffab09fe2861297df1e0be265818c.jpg17 KB · Views: 54 -

205102-3bf89f8ae9046dd4082a832d34b6ecd7.jpg34 KB · Views: 59

205102-3bf89f8ae9046dd4082a832d34b6ecd7.jpg34 KB · Views: 59 -

205101-b3b191c39816d6292950acf9b37227e4.jpg22.1 KB · Views: 60

205101-b3b191c39816d6292950acf9b37227e4.jpg22.1 KB · Views: 60 -

205100-f15121acf05531678c08fe328e5bec13.jpg23.1 KB · Views: 63

205100-f15121acf05531678c08fe328e5bec13.jpg23.1 KB · Views: 63