You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Moving stuff in a small workshop

- Thread starter mrsbruce

- Start date

Carl Wilson

Member

- Messages

- 2,009

- Location

- Moray

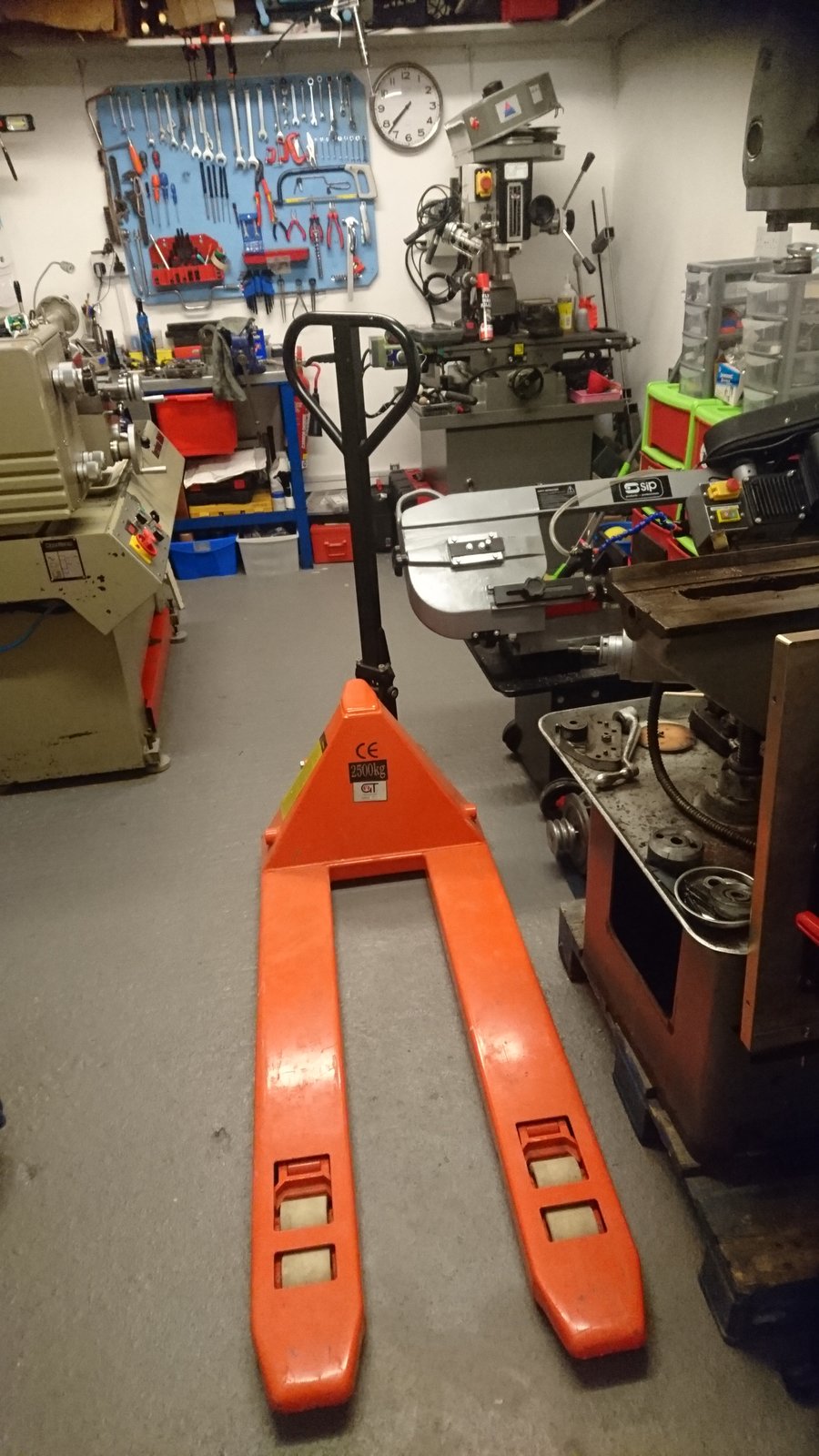

Here is the folding engine crane and the pallet truck in my workshop. Neither normally live in here, but I'm using them a lot for the mill restoration. As you can see, they take up a lot of space. It's been said, storing these things when not in use is the main issue. If I didn't have a shed then I'd have them outside somewhere, well greased up with a tarp over them.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,329

- Location

- Near to Cross Hands Llanelli SouthWales GB

I made two A frames out of bits of interlocking tube ( legs of a 24 foot circular scrap trampoline off free cycle ) the sections are in two foot lengths made up two so reader bars for rthe legs and a top bar wuth four pegs to go in the top end of the tubes I had a simple £9 fence tensioner , car puller out the mud device with a 2 ton breaking strain cable of aeroplane grade stainless steel cable . & a cheap Haltrac six to one pulley set ( halfords or eBay )

when assembled the frame looked like a swing in the council play park

With this I've lifted two 2'x3' x 2"" paving slabs seven foot up to the top of my brick built smoker to make the roof . I've also lifted a rock in my garden some four feet long and two fee tall , to feet wide egg shape rock , lifted it to a home made roller under boards plat form . made a path of planks down the garden an moved the rock appox 30 feet ( the roller were also part of the trampoline leg tubing

So could you sketch up a dismantlable frame to use tubes the only really big bit would be the transom as it would need four fingers to fit the tubes .

Sadly I cut my A frames & transom up and used if for something else that I gave to a friend otherwise I'd have some picture of it.

Thinking again of those tubes .

I got hold of an old oil fired boiler , cut it apart and used the steel & heat exchanger plates for things as they were 5 mm thick .

I made a foot plate with a spigot out of one of these exchanger plates for the tubes & put an eye in one tube .. slipping the Haltrc pulley set on a strong chin shackled in the eye & a chain & shackle in the other end of the pulley set to attach it to the spreader bar . & a tube over the the spigot .

I inserted more inter locking tubes in between and made a " flag pole " nearly 12 feet tall . I used this and a spreader bar to change out 22 rotted fence panels , and put 22 rot treated 4 x 6 panels back in their place in H section concrete posts

I've also used the tubes and foot plates & the transom to lift things off the garage floor to above bench height A long leg on the floor and a short one on the bench . Pushed a plank covered in thick plastic sheet on the bench , hold the free end off the frame using a ratchet strap then slid the item across the plank on to the bench .

PS I'm 69 almost and triple crippled , these days I don't lift anything much more than 10 kg ..I can't .

I've also got the wheel chair hoist that came out one of my motability vehicles . This is bolted to the wall near the garage door so I can lift stuff in/ out my trolley or off my sack barrow & put it on the welding bench ..it's rated at 100Kg.

when assembled the frame looked like a swing in the council play park

With this I've lifted two 2'x3' x 2"" paving slabs seven foot up to the top of my brick built smoker to make the roof . I've also lifted a rock in my garden some four feet long and two fee tall , to feet wide egg shape rock , lifted it to a home made roller under boards plat form . made a path of planks down the garden an moved the rock appox 30 feet ( the roller were also part of the trampoline leg tubing

So could you sketch up a dismantlable frame to use tubes the only really big bit would be the transom as it would need four fingers to fit the tubes .

Sadly I cut my A frames & transom up and used if for something else that I gave to a friend otherwise I'd have some picture of it.

Thinking again of those tubes .

I got hold of an old oil fired boiler , cut it apart and used the steel & heat exchanger plates for things as they were 5 mm thick .

I made a foot plate with a spigot out of one of these exchanger plates for the tubes & put an eye in one tube .. slipping the Haltrc pulley set on a strong chin shackled in the eye & a chain & shackle in the other end of the pulley set to attach it to the spreader bar . & a tube over the the spigot .

I inserted more inter locking tubes in between and made a " flag pole " nearly 12 feet tall . I used this and a spreader bar to change out 22 rotted fence panels , and put 22 rot treated 4 x 6 panels back in their place in H section concrete posts

I've also used the tubes and foot plates & the transom to lift things off the garage floor to above bench height A long leg on the floor and a short one on the bench . Pushed a plank covered in thick plastic sheet on the bench , hold the free end off the frame using a ratchet strap then slid the item across the plank on to the bench .

PS I'm 69 almost and triple crippled , these days I don't lift anything much more than 10 kg ..I can't .

I've also got the wheel chair hoist that came out one of my motability vehicles . This is bolted to the wall near the garage door so I can lift stuff in/ out my trolley or off my sack barrow & put it on the welding bench ..it's rated at 100Kg.

Cuthy246

Member

- Messages

- 940

- Location

- Scotland, Highlands

We have these at work, really handy for moving stuff about and when not being used to move stuff are used as another work surface.

https://www.mobile-scissor-tables.co.uk/product/scissor-lift-trolley-350kg-sc350dmjcb/

https://www.mobile-scissor-tables.co.uk/product/scissor-lift-trolley-350kg-sc350dmjcb/

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,700

- Location

- Leeds, West Yorkshire

Hi, Someone on here (I think it was @CompoSimmonite) bought a pallet truck and it went up to bench height when most don't. It might be worth a look for because they're easier to move things around.

Colin

^^^

this.

can be had for around £100 2nd hand

also really good for breaking down pallets.

damhikt

damhiktbigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,700

- Location

- Leeds, West Yorkshire

i also had a "bath hoist" rated for 150kgs (i think) which was useful for lifting machinery off the trailer.

think i sold it to someone on here.

theyre c. £100 as well, although they do need a solid ceiling to attach them to.

think i sold it to someone on here.

theyre c. £100 as well, although they do need a solid ceiling to attach them to.

jsf55

Forum Supporter

- Messages

- 1,770

- Location

- Sunny Swansea

Hand stacker truck like this https://www.ebay.co.uk/itm/Manual-F...677735?hash=item4b6a392767:g:7poAAOSwKzVdYs3L I used one every day when I worked in a press shop

Farside

Badly Welded Man

- Messages

- 6,369

- Location

- Ireland

with dealing with beams an engine lift is more usefull than you may think as you get older

can lift loads of things with them

Engine hoist, we don' need no steenken engine hoist...

Farside

Badly Welded Man

- Messages

- 6,369

- Location

- Ireland

I stopped watching when he used the end of the dial caliper to scratch the middle line.

Butcher.

rtcosic

Forum Supporter

- Messages

- 2,967

- Location

- Warwickshire

If you can keep an unusually tidy workshop and leave two sides completely clear. I could imagine making a Traveling Gantry and one of those 240V electric winches which appear in Lidl from time to time.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,678

- Location

- Keeler crater

A problem that's not been mentioned with cranes is they need a lot of head room, you need to fit the jib or gantry, chains/straps/etc and the item to be lifted in the space between a workbench and the ceiling, which in a shed might not be very much space at all. A scissor lift table might be better for this reason, the thing being lifted does need shimmying on and off though. When it's not being used it can function as a bit more bench space.

RobCox

Member

- Messages

- 546

- Location

- Cambridge, UK

Another idea, if your putting up your workshop from scratch as I did a few years ago, is to install a couple of RSJs from end to end of the building and run a gantry between them.

My workshop is only about 2.5 x 5m and there's no spare floor space for a travelling gantry. This enables me to lift and shift things like the lathe and mill within the workshop with ease.

The hoist was a bought in item. The rest of the assembly was shop made.

Obviously useless for lifting anything outside the workshop to move it in. For that I've got a palette truck and helpful neighbours.

My workshop is only about 2.5 x 5m and there's no spare floor space for a travelling gantry. This enables me to lift and shift things like the lathe and mill within the workshop with ease.

The hoist was a bought in item. The rest of the assembly was shop made.

Obviously useless for lifting anything outside the workshop to move it in. For that I've got a palette truck and helpful neighbours.

Carl Wilson

Member

- Messages

- 2,009

- Location

- Moray

I can't help thinking that although there are a lot of good ideas here - and I've taken note of a few - we still don't seem to have solved the core problem of how one moves heavy equipment in the small home shop.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,700

- Location

- Leeds, West Yorkshire

I can't help thinking that although there are a lot of good ideas here - and I've taken note of a few - we still don't seem to have solved the core problem of how one moves heavy equipment in the small home shop.

yes we have.

its the same answer as always:

"you need a bigger shed"

gaz1

Member

- Messages

- 20,515

- Location

- westyorkshire

ive used an engine lift and also the I beam lifters

they have there uses but for traveling stuff with them not too good the smaller the wheels the more they can tip over more so with unlevel ground or even on concrete base

this thing handy to strap engines to the base of it and wheel it for a home item really handy to have its air filled tyres at that

i find with engine hoist a little big on the legs same with beam hoists

these are the beam hoists mentioned

this one was better loved the idea you could fit something over the are and lift it just like a forklift truck lift it also folded to transport them

could be used like a table can be used like a hoist as they have forks 3"x2"

only downfall to them wheels wasnt big enough to wheel around properly ok on a solid clean floor get any bits or high pieces you knew about it

they have there uses but for traveling stuff with them not too good the smaller the wheels the more they can tip over more so with unlevel ground or even on concrete base

this thing handy to strap engines to the base of it and wheel it for a home item really handy to have its air filled tyres at that

i find with engine hoist a little big on the legs same with beam hoists

these are the beam hoists mentioned

this one was better loved the idea you could fit something over the are and lift it just like a forklift truck lift it also folded to transport them

could be used like a table can be used like a hoist as they have forks 3"x2"

only downfall to them wheels wasnt big enough to wheel around properly ok on a solid clean floor get any bits or high pieces you knew about it

colnerov

Member

- Messages

- 5,096

- Location

- Nr Gatwick UK

Hi, Most of these suggestions are a bit over the top for a small shed and subsequent storage problem afterwards. The simplest to my mind is to lure passing neighbours in to assist with the promise of sustenance, they can then be safely stored back in their homes out of the way until the next time. I know this is not ideal for you but needs must.

Colin

Colin

slim_boy_fat

Member

- Messages

- 29,363

- Location

- Scottish Highlands