the snooper

getting older by the day

- Messages

- 21,063

- Location

- Hull UK

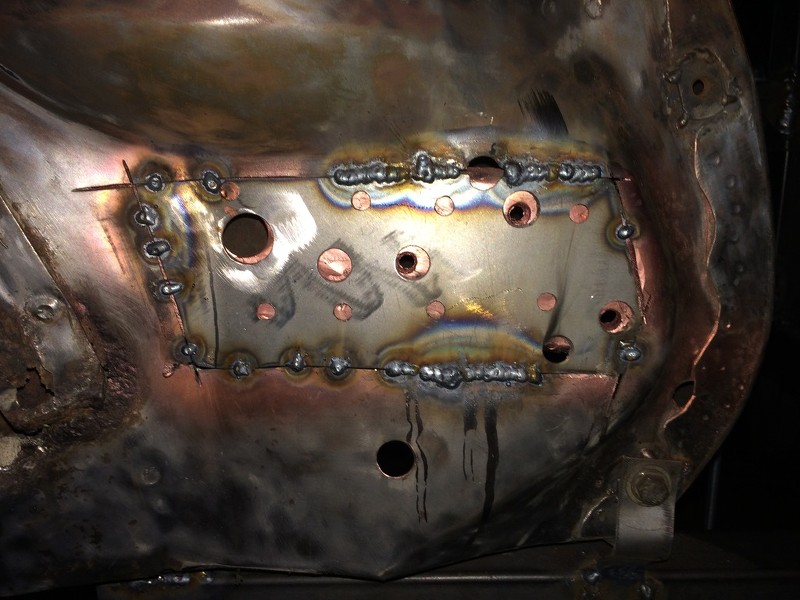

the last picture you can see it has been welded before as you have left the old weld there, you need to remove the old weld to do a better job its pointless welding on top of weld

To make a more accurate template for a patch, I have found it useful to put a few lines of masking tape over the area, then mark on the tape and cut the rusty bit out. The masking tape comes with it, and gives you the exact size. This is especially useful where there is a curve in a panel - you flatten the tape out, use it as a template, then put the curve into the patch before welding it in.

Hello,

Firstly what I would do If i were you is to actually clean off all the rust in the first place. Don't use angle grinder for it, use a wire brush which is less abrasive to surrounding metal. Any bits that are beyond repair you cut off. But you have to remove all the rust first in order to be able to weld a good piece in otherwise it will start to rust within months again. Sorry for being harsh, but with above repair you did more harm than actual repair, as this particular place was not clean enough in the first place to weld patch in.

Yes, use a rust inhibitor, but at places that have been cleaned off first. Stop using a copper paint and go for high zinc content primer. Copper rusts where zinc protects. So basically a clean off first, then rust inhibitor, wipe it dry after 15-20 min and light coat of zinc primer (only use high content ones like 98% or so). Weld edges do not have to be covered in primer, so you can leave a margin there. But remaining parts of plate should be covered with it.

Start using smaller diameter cutting discs and apply less pressure whilst cutting - this will provide you with better cut surfaces (you do know you have to clean off the face of the cut after cutting it with disc?) and you will not damage the surrounding areas. Same when you remove excess welds, apply light pressure, otherwise you burn the metal and it will start to rust despite best protection treatment applied later.

Start using a cardboard templates instead of trimming a piece of metal so it fits. This will save you a considerable amount of time and metal sheet.

Meal sheet has to be cleaned off from its surface coating. You will be able to weld it MUCH more easily, especially on gauge steel.

Consider tapping all the welds in with a small mallet first before you skim them.

After you finish with the area wipe it off, de-grease, apply zinc oxide primer and zinc primer (allow cure times respectively). You can use a weld seam on the welds to completely seal them in case.