You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Microwave oven Idea

- Thread starter Memmeddu

- Start date

FergalFarty

Member

- Messages

- 203

- Location

- Bristol

This guy on Youtube has made a few things using microwave parts

https://www.youtube.com/user/darus627/videos

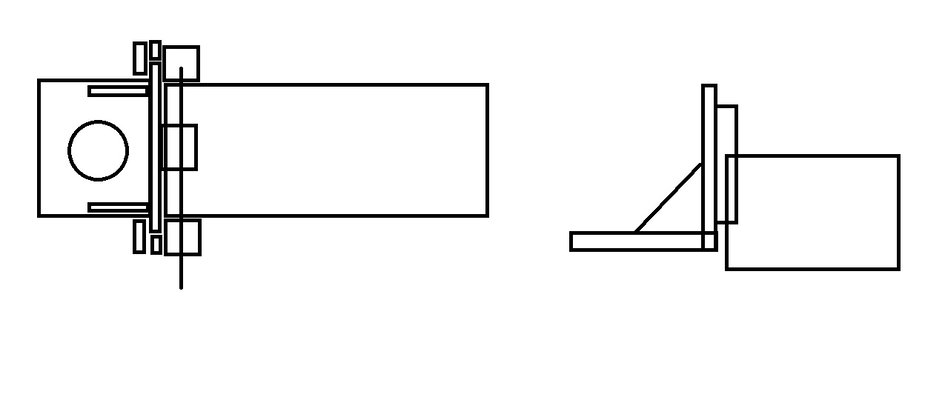

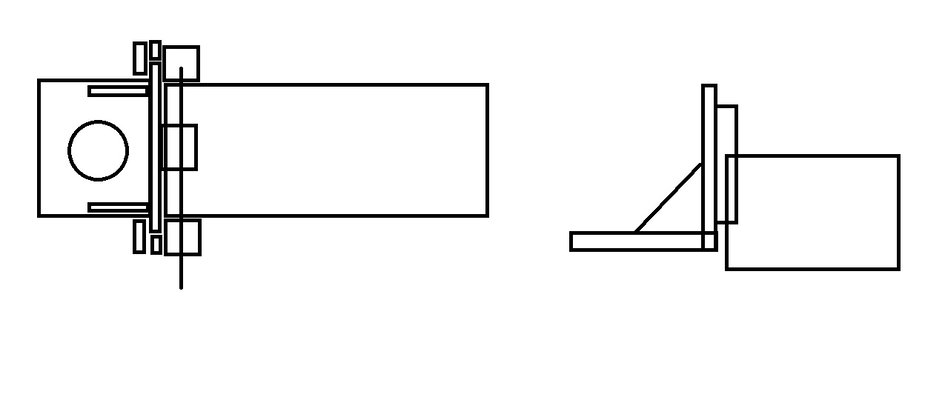

Here's a DIY mag drill

https://www.youtube.com/user/darus627/videos

Here's a DIY mag drill

visor_down

Member

- Messages

- 413

- Location

- UK

Sounds good, if you're not familiar with dismantling them watch out for the insulators, contain nasty stuff that you do not want to breathe in.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,814

- Location

- NE London - UK

if you're not familiar with dismantling them watch out for the insulators, contain nasty stuff that you do not want to breathe in.

That used to be true but not so now. The beryllium oxide in the magnetron ceramic insulator has long sonce been replaced by aluminium oxide.

What you do need to be aware of is the potential for a large shock from the capacitor if the oven has recently been used.

Memmeddu

Member

- Messages

- 5,338

- Location

- Italia Sardegna

When was 13 I build my first welder from mots burned in a day ,I think that I made something like 4 stick welders before to got a proper oneSounds good, if you're not familiar with dismantling them watch out for the insulators, contain nasty stuff that you do not want to breathe in.

Then I made two spot welders ,a battery charger ,an insulation transformer ,some inductances ect..

I know that is not a good idea crush a magnetron

Generally I cut the copper wire to allow me to extract the dangerous part and recycle the magnets

Now for the mag-drill I will use the transformer ,I will cut the welds and extract the secondary winding without cut it

Now the question is which kind of drill use ?

Was thinking about concrete mixer or something like this to have low speed and high torque

Memmeddu

Member

- Messages

- 5,338

- Location

- Italia Sardegna

I started the project of the mag drill

I simply tear down the oven and put out the transformer .

Removed the secondary winding ,power on using a car battery ...

Is a single transformer enough strong to control the moment of the drill?

I saw the video and he used two mot

I tried to pull the transformer but I moved the bench so I think that is enough strong

But I'm not sure what do you think about?

So have intention to use metal only for structural parts of the project ,an a use an elettrician box to put into all the wires the AC DC adapter the SCR controller and the switches

Was also thinking to put a safety switch on the contact plate as if the drill jumps it will automatically get off

So a safety features

I simply tear down the oven and put out the transformer .

Removed the secondary winding ,power on using a car battery ...

Is a single transformer enough strong to control the moment of the drill?

I saw the video and he used two mot

I tried to pull the transformer but I moved the bench so I think that is enough strong

But I'm not sure what do you think about?

So have intention to use metal only for structural parts of the project ,an a use an elettrician box to put into all the wires the AC DC adapter the SCR controller and the switches

Was also thinking to put a safety switch on the contact plate as if the drill jumps it will automatically get off

So a safety features

gaz1

Member

- Messages

- 20,081

- Location

- westyorkshire

ive got one of these

https://www.ebay.co.uk/itm/Hand-Dri...445422&hash=item3b20cff1be:g:Cv8AAOSw5sBbhlR4

as your drilling it comes loose as you put pressure on it or it slides up with the plastic nothing worse than that drill spinning and it coming loose

strengtheners to keep drill in line and also easier to fasten the front plate usine the lathes method of a slider with even a lathes cogs and tooth bar is what id consider

https://www.ebay.co.uk/itm/Hand-Dri...445422&hash=item3b20cff1be:g:Cv8AAOSw5sBbhlR4

as your drilling it comes loose as you put pressure on it or it slides up with the plastic nothing worse than that drill spinning and it coming loose

strengtheners to keep drill in line and also easier to fasten the front plate usine the lathes method of a slider with even a lathes cogs and tooth bar is what id consider

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 20,170

- Location

- Going Away.

Still micro wave related.

The glass platter is great when chilled, to serve cold drinks on. Plus great to serve cream cakes off as well.

The door micro switches are a 3 way small switch, great for projects.

The magnets great to make a earth clamp etc.

The thin metal, when cleaned makes great welding practise.

Timer switch can be used, as a timer.

If it has a grill that makes a great small paint oven.

The glass platter is great when chilled, to serve cold drinks on. Plus great to serve cream cakes off as well.

The door micro switches are a 3 way small switch, great for projects.

The magnets great to make a earth clamp etc.

The thin metal, when cleaned makes great welding practise.

Timer switch can be used, as a timer.

If it has a grill that makes a great small paint oven.

Memmeddu

Member

- Messages

- 5,338

- Location

- Italia Sardegna

I think that is to dangerous for me

This looks like far more fun! Watch at about 2.10

I don't like guns

Or better I love guns ,the history ,the mechanism how they works etc

But a weapon is always something born to kill so nothing good can be make by any kind of weapon

Memmeddu

Member

- Messages

- 5,338

- Location

- Italia Sardegna

Micro switch are in the storage nowStill micro wave related.

The glass platter is great when chilled, to serve cold drinks on. Plus great to serve cream cakes off as well.

The door micro switches are a 3 way small switch, great for projects.

The magnets great to make a earth clamp etc.

The thin metal, when cleaned makes great welding practise.

Timer switch can be used, as a timer.

If it has a grill that makes a great small paint oven.

I always take them in the storage because they are useful ,I have something like 20 of them

Magnets im looking for a use

With the grill and the rest of the oven I made a little rod oven (180°C or something like this)

slim_boy_fat

Member

- Messages

- 29,532

- Location

- Scottish Highlands

This looks like far more fun! Watch at about 2.10

I'll not be trying any of that, any time soon.....

aguycalledsteve

Member

- Messages

- 548

- Location

- Mansfield

Or Make it Extreme

I have vice and cutter envy.

Memmeddu

Member

- Messages

- 5,338

- Location

- Italia Sardegna

So little test this morning

Put the mot on the welding bench

Used an F clamp as an handle

Used a 1¹/4 inch tube and a prybar as a lever

Put my own weight on the very end of the lever after gave power to the mot

I used 12V 4A

This little thing is powerful I think that can manage the power of a 1600W drill

Put the mot on the welding bench

Used an F clamp as an handle

Used a 1¹/4 inch tube and a prybar as a lever

Put my own weight on the very end of the lever after gave power to the mot

I used 12V 4A

This little thing is powerful I think that can manage the power of a 1600W drill