You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making washers on a lathe.

- Thread starter God mode restorations

- Start date

God mode restorations

Member

- Messages

- 8,100

- Location

- uk colchester

Yes I agree. But The main reason I try to make as much as posible is the fact that when even I go to different stores or places to get washers or bolt ect is they never have what I want. They can't be bothered to order it.the washer on my tractor unit are 5 mm thick.so I have to replace like for like. If I can't then I will make.just the way I am. But have found a place on the net that have what I want so all good.Its a question of using the grey matter, spending 4 or 5 hours or more even, making something you can buy in the local hardware for a fiver is a fools errand.

ronan

Member

- Messages

- 11,282

I only ever make them if they're odd, like a stepped face to retain a spring or a really big ID. They take far too long unless you have a capstan lathe.

Maker is now daydreaming about, and heading off to ebay to look at .................capstan lathes !

God mode restorations

Member

- Messages

- 8,100

- Location

- uk colchester

I was just intrest ed in how they are made on a lathe.and the tooling needed and used to perform the task. Am totally new to the lathe side of things.but look forward to doing stuff over winterI only ever make them if they're odd, like a stepped face to retain a spring or a really big ID. They take far too long unless you have a capstan lathe.

God mode restorations

Member

- Messages

- 8,100

- Location

- uk colchester

It's ok. I don't take them as negative. I asked a question and I appreciate people's opinions and there thoughts about hat I have asked.it's all goodI can't understand all the negative posts. If it makes you happy doing it, then do it. I do lots of things that have no real value to anyone but myself.

God mode restorations

Member

- Messages

- 8,100

- Location

- uk colchester

I will indeed Mr shiney. .thanksIt will cost you more to Tool up and make them than you will EVER make back. Use your lathe time to learn useful skills.

rory1

Member

- Messages

- 1,167

- Location

- Macclesfield

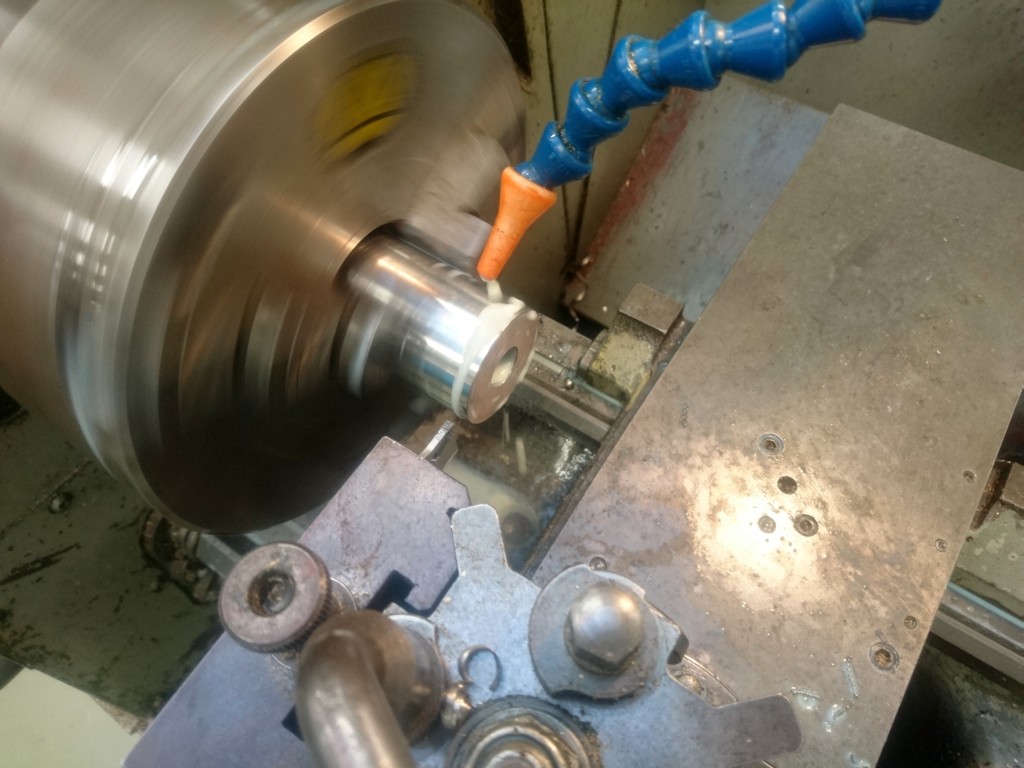

The way I would do it is this, chuck material up with as much sticking out of the chuck as you can get away with without too much overhang, face off, turn OD, centre drill, drill to required size , bore out if required. Part off to length and then keep parting off till you run out of hole.

If you fancy making washers then make some washers, it's your decision if it's cost effective, even if it's not cost effective it's good practice at the basic lathe operations of facing, drilling , boring , turning and parting .

If you fancy making washers then make some washers, it's your decision if it's cost effective, even if it's not cost effective it's good practice at the basic lathe operations of facing, drilling , boring , turning and parting .

rory1

Member

- Messages

- 1,167

- Location

- Macclesfield

I can't think of many more useful basic lathe skills than the operations required to make a washer, facing, turning, drilling, boring and parting.

I'm sure there are many time served chaps out there that honed their basic skills as an apprentice by making basic items such as washers?

If in the future spencer 427 wants to make a bush or a plain bearing for one of his trucks then it will use the same principles and skills as when he made his washers, if he wants to screw cut a shaft then he will face off and turn his material before he cuts his thread, all of which ( apart from the screw cutting) he mastered whilst making a load of washers.

By the way, I'm not arguing that making washers may be non profit making but it is skill building

I'm sure there are many time served chaps out there that honed their basic skills as an apprentice by making basic items such as washers?

If in the future spencer 427 wants to make a bush or a plain bearing for one of his trucks then it will use the same principles and skills as when he made his washers, if he wants to screw cut a shaft then he will face off and turn his material before he cuts his thread, all of which ( apart from the screw cutting) he mastered whilst making a load of washers.

By the way, I'm not arguing that making washers may be non profit making but it is skill building

Wendelspanswick

Member

- Messages

- 6,471

I turned up 60 washers on the lathe for a customer, they were for a number of sluice gates that were being refurbished and they had to be made of bronze in imperial sizes.

It was a nice easy job, had about 3" projecting out the chuck, turned the bar stock down to the correct OD, run a drill through with the tailstock about 2 inches in, rotate the toolpost to bring the blade type parting tool in, part off slices till you get to the end of your drilling, extend out another 2" from the chuck and repeat.

At the end of the day the tolerances and finish were not critical as they would spend the majority of their life underwater and never be seen.

The customer was happy.

It was a nice easy job, had about 3" projecting out the chuck, turned the bar stock down to the correct OD, run a drill through with the tailstock about 2 inches in, rotate the toolpost to bring the blade type parting tool in, part off slices till you get to the end of your drilling, extend out another 2" from the chuck and repeat.

At the end of the day the tolerances and finish were not critical as they would spend the majority of their life underwater and never be seen.

The customer was happy.

Screwdriver

Forum Supporter

- Messages

- 11,060

Problem with parting off is it is the single most horrible chore on a lathe! (Next to cleaning it).

Parting off 5mm washers is going to turn more than half your stock to swarf and I dread to think how many busted parting off tools you'll end up with. I thought the superglue trick was worth having a play with....

S.

Parting off 5mm washers is going to turn more than half your stock to swarf and I dread to think how many busted parting off tools you'll end up with. I thought the superglue trick was worth having a play with....

S.

God mode restorations

Member

- Messages

- 8,100

- Location

- uk colchester

Thanks for your reply Rory. It will give me some practice over the winter and get familiar with the machine. I have a huge box of off cuts of different sizes and diameters so have plenty to get on wiyhThe way I would do it is this, chuck material up with as much sticking out of the chuck as you can get away with without too much overhang, face off, turn OD, centre drill, drill to required size , bore out if required. Part off to length and then keep parting off till you run out of hole.

If you fancy making washers then make some washers, it's your decision if it's cost effective, even if it's not cost effective it's good practice at the basic lathe operations of facing, drilling , boring , turning and parting .

Wendelspanswick

Member

- Messages

- 6,471

What don't you like about parting? I never have any issues since I switched to a blade type parting tool and I lock the carriage before I powerfeed the cross slide in.Problem with parting off is it is the single most horrible chore on a lathe! (Next to cleaning it).

Parting off 5mm washers is going to turn more than half your stock to swarf and I dread to think how many busted parting off tools you'll end up with. I thought the superglue trick was worth having a play with....

S.

brightspark

Member

- Messages

- 41,473

- Location

- yarm stockton on tees

u will soon get peed off after u have parted half a dozen knacked a few and nearly wrecked your lathe and tool when u get a dig in

brightspark

Member

- Messages

- 41,473

- Location

- yarm stockton on tees

even on a new machine its more robust a rear tool post u don't get dig insHave a rear mounted holder for parting off on the Colchester works a lot smother than holding in tool post, it is an old machine though

even on a new machine its more robust a rear tool post u don't get dig ins

Yep. I use a rear tool post on mine. I still would not **** around making washers though!!

RaceDiagnostics

Member

- Messages

- 3,543

- Location

- Broughty Ferry

.

.