You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lincoln Bester 210ND arc welder nor working

- Thread starter JOEPRO

- Start date

JOEPRO

Member

- Messages

- 5,297

- Location

- UK

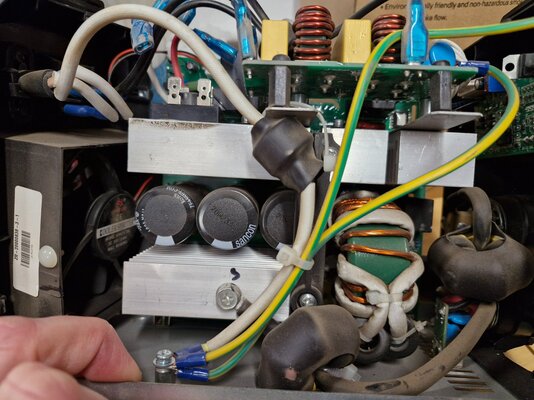

I got a better look at this Lincoln today. I discovered no AC at the main board. The 4 pin diode bridge rectifier was bad.

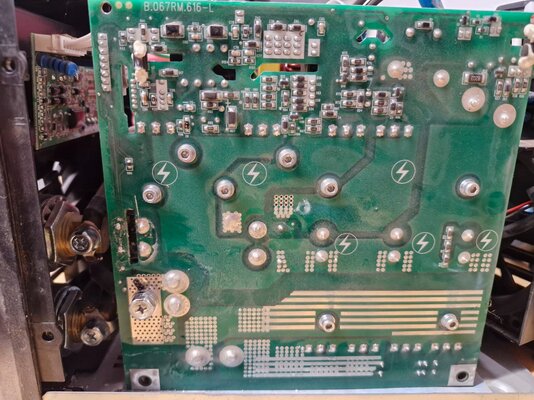

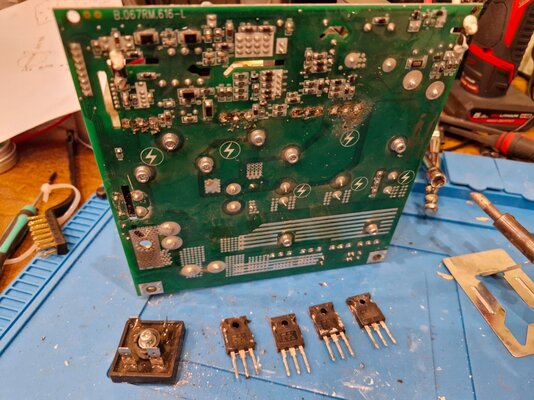

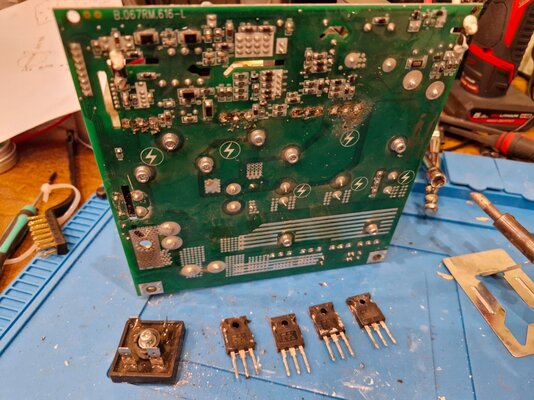

I wanted to check why so I checked the IGBTs which are a common failure on modern inverter welders. Sure enough 3x of them on one row tested bad. There are 8 total, I removed the top row of 4x and I will replace that row. The bottom row all tested good so ill leave them alone. I tested the small components connecting the blown IGBTs and they appeared OK too, not open circuit.

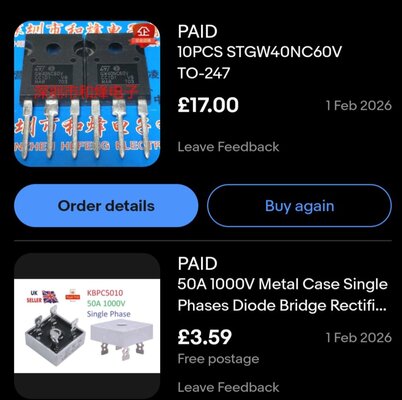

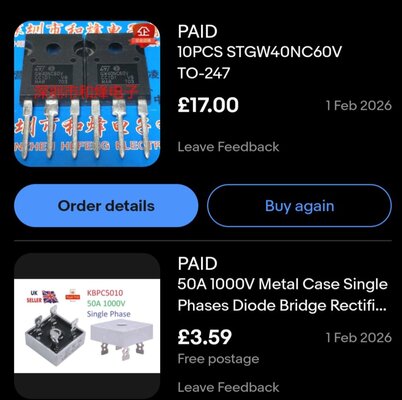

Parts ordered, cheap enough too. 10 so ill have some spare.

I wanted to check why so I checked the IGBTs which are a common failure on modern inverter welders. Sure enough 3x of them on one row tested bad. There are 8 total, I removed the top row of 4x and I will replace that row. The bottom row all tested good so ill leave them alone. I tested the small components connecting the blown IGBTs and they appeared OK too, not open circuit.

Parts ordered, cheap enough too. 10 so ill have some spare.

Good progress so far!

See the warning in Post #4 here:

A good opportunity to check the gate switching pulses with your new 'scope! See how to do this safely in Post #21 here:

See the warning in Post #4 here:

When IGBTs go short-circuit, they often conduct high voltages from the collector/emitter circuits through to the gate. This destroys the gate driver circuitry. You need to trace the circuit path from the gate of the IGBT module back to the control logic, and check it. There may be Zener diodes, resistors, a dedicated driver chip or a pulse transformer involved.

Another problem can be that installing a new IGBT with the gate driver still damaged can self-charge the capacitance of a floating gate. The IGBT will then conduct fully on, and blow itself up again. Therefore you would need to...

Another problem can be that installing a new IGBT with the gate driver still damaged can self-charge the capacitance of a floating gate. The IGBT will then conduct fully on, and blow itself up again. Therefore you would need to...

Another thread about Parweld inverter welder repairs that might be helpful:

In post #24 it mentions a suggestion taken from a Selco welder repair manual that recommends using a low-voltage current-limited DC supply from a bench power supply instead of the 325v DC rectified from the AC mains. This would be done after replacing valuable IGBTs to confirm that the gate drive circuits are working correctly. The outputs from the bridge rectifier(s) are disconnected from the inverter power switching...

WWS200, Parweld XTS162 welder repairs

Hi Chaps, I recently bought a known faulty WWS200 MMA/lift rig welder. It doesn’t look as if it has even struck an arc as it is immaculate condition. The issue is that when plugged in the welder is completely dead. I only got it this afternoon so have only had chance to take a quick look...

www.mig-welding.co.uk