Nomad

Member

- Messages

- 2,312

- Location

- North Devon (for how long?)

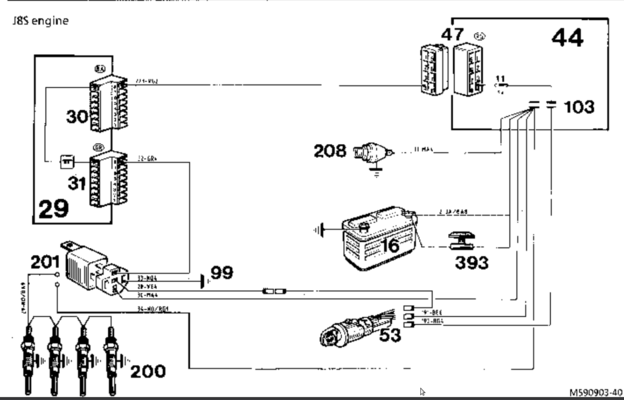

Is anyone familiar with rebuilding late 1980s Renault 2.1D engines (engine code 852 not the more common J8S )

I do a lot of work on older engines (1960s-1990s) and often remove the head & sump from tired engines so I can push the piston/conrod up & out, inspect things then refit with new pistons & rings (or just rings), new big end bearings, etc.

Today I found a new problem, I've removed the head, removed the sump, pulled 1 big end and saw - as expected - the journal is ok but the bearing shell has worn through the coating.

The place I order spares from has a 60% sale on 2,1D parts (selling off due to not popular these days) so I put in a quick order and got piston rings, big end shells, new head bolts (last set in stock !), gaskets etc...

It's only when I went back to do more work I found the piston/conrod won't move up as the conrod is too big to fit through the cylinder It won't move down as the crank is blocking it.

It won't move down as the crank is blocking it.

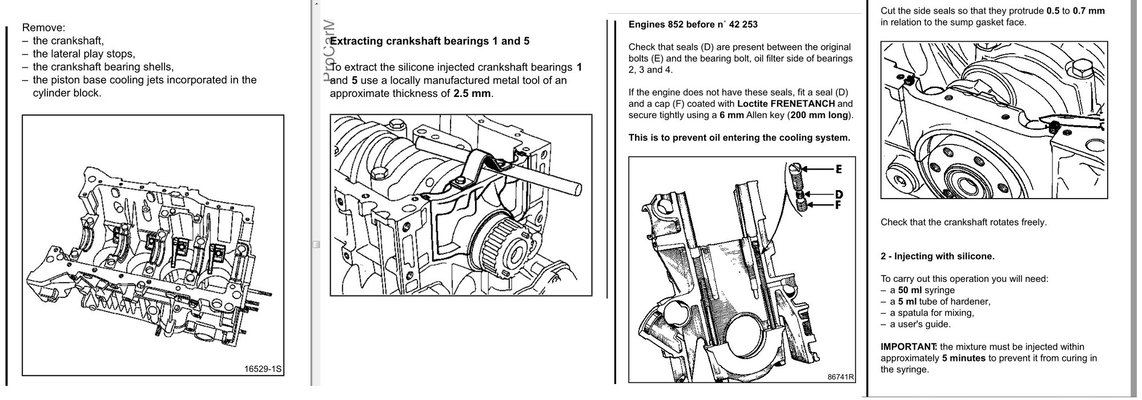

The motor has wet liners, the factory method is to remove the liners & pistons as a unit then separate them, disturbing the liners gets very complicated (and expensive) very quickly so I want to avoid.

A friend is rebuilding a 2.5D of the same age and they did my usual - head off - sump off - push pistons up & out ... no problems. I'm guessing Renault used the same chunky 2.5D conrods that are too big to fit through my 2.1D bores.

The bores have slight wear so I'm declaring the engine scrap unless I can find a DIY fix as as it's not worth doing a full rebuild (new bores & pistons are out of budget)

Pulling the engine out & removing the crank is DIY'able but hard work on my own with no engine crane. Refitting the crank looks too complicated for DIY on the driveway and will add £££ for main bearings, seals & gaskets etc so is not an option.

What are my options? I'd rather not fit a new engine but is a 2.5D or 2.5D-turbo a straight swap? (my engine is pre-immobiliser, any replacement needs to be same as rewiring for an immobiliser isn't happening)

Before I put it in this engine in the skip and find another engine I'd like to see what's possible ...

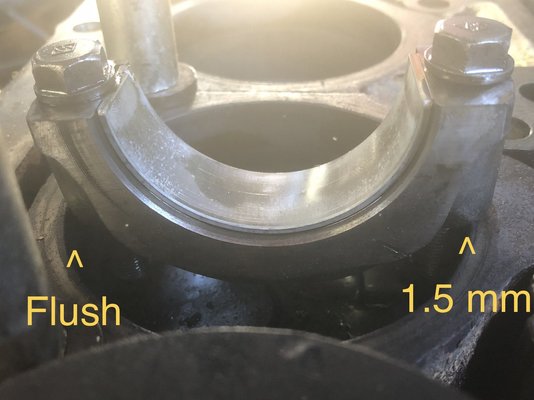

Theoretically, if you *needed* to shave 1.5mm off the width of a chunky 87.5mm conrod so it would pass through a 86mm bore (and the conrod was still fitted in the block restricting access) what tools would you use?

Question2: how long would you expect it to last before it self destructs

Even if it blows up when I try to start it, it will have cost me nothing but time....

I do a lot of work on older engines (1960s-1990s) and often remove the head & sump from tired engines so I can push the piston/conrod up & out, inspect things then refit with new pistons & rings (or just rings), new big end bearings, etc.

Today I found a new problem, I've removed the head, removed the sump, pulled 1 big end and saw - as expected - the journal is ok but the bearing shell has worn through the coating.

The place I order spares from has a 60% sale on 2,1D parts (selling off due to not popular these days) so I put in a quick order and got piston rings, big end shells, new head bolts (last set in stock !), gaskets etc...

It's only when I went back to do more work I found the piston/conrod won't move up as the conrod is too big to fit through the cylinder

It won't move down as the crank is blocking it.

It won't move down as the crank is blocking it.The motor has wet liners, the factory method is to remove the liners & pistons as a unit then separate them, disturbing the liners gets very complicated (and expensive) very quickly so I want to avoid.

A friend is rebuilding a 2.5D of the same age and they did my usual - head off - sump off - push pistons up & out ... no problems. I'm guessing Renault used the same chunky 2.5D conrods that are too big to fit through my 2.1D bores.

The bores have slight wear so I'm declaring the engine scrap unless I can find a DIY fix as as it's not worth doing a full rebuild (new bores & pistons are out of budget)

Pulling the engine out & removing the crank is DIY'able but hard work on my own with no engine crane. Refitting the crank looks too complicated for DIY on the driveway and will add £££ for main bearings, seals & gaskets etc so is not an option.

What are my options? I'd rather not fit a new engine but is a 2.5D or 2.5D-turbo a straight swap? (my engine is pre-immobiliser, any replacement needs to be same as rewiring for an immobiliser isn't happening)

Before I put it in this engine in the skip and find another engine I'd like to see what's possible ...

Theoretically, if you *needed* to shave 1.5mm off the width of a chunky 87.5mm conrod so it would pass through a 86mm bore (and the conrod was still fitted in the block restricting access) what tools would you use?

Question2: how long would you expect it to last before it self destructs

Even if it blows up when I try to start it, it will have cost me nothing but time....

many thanks! No need to do anything yet as I'm still looking at options but first thoughts are :

many thanks! No need to do anything yet as I'm still looking at options but first thoughts are :