- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knurling

- Thread starter Mikes

- Start date

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

I watched a YouTube vid a while back where the single or double roller type was clocked 3* set adjusting the height and x axis travel for DOC, you don't need to to workout the dia. I have tried it, and it worked on the piece of round I through in the lathe out of curiosity, all I did was true it up, and run the knurl down it. I’ll go root may still have it

citizen kane

Member

- Messages

- 269

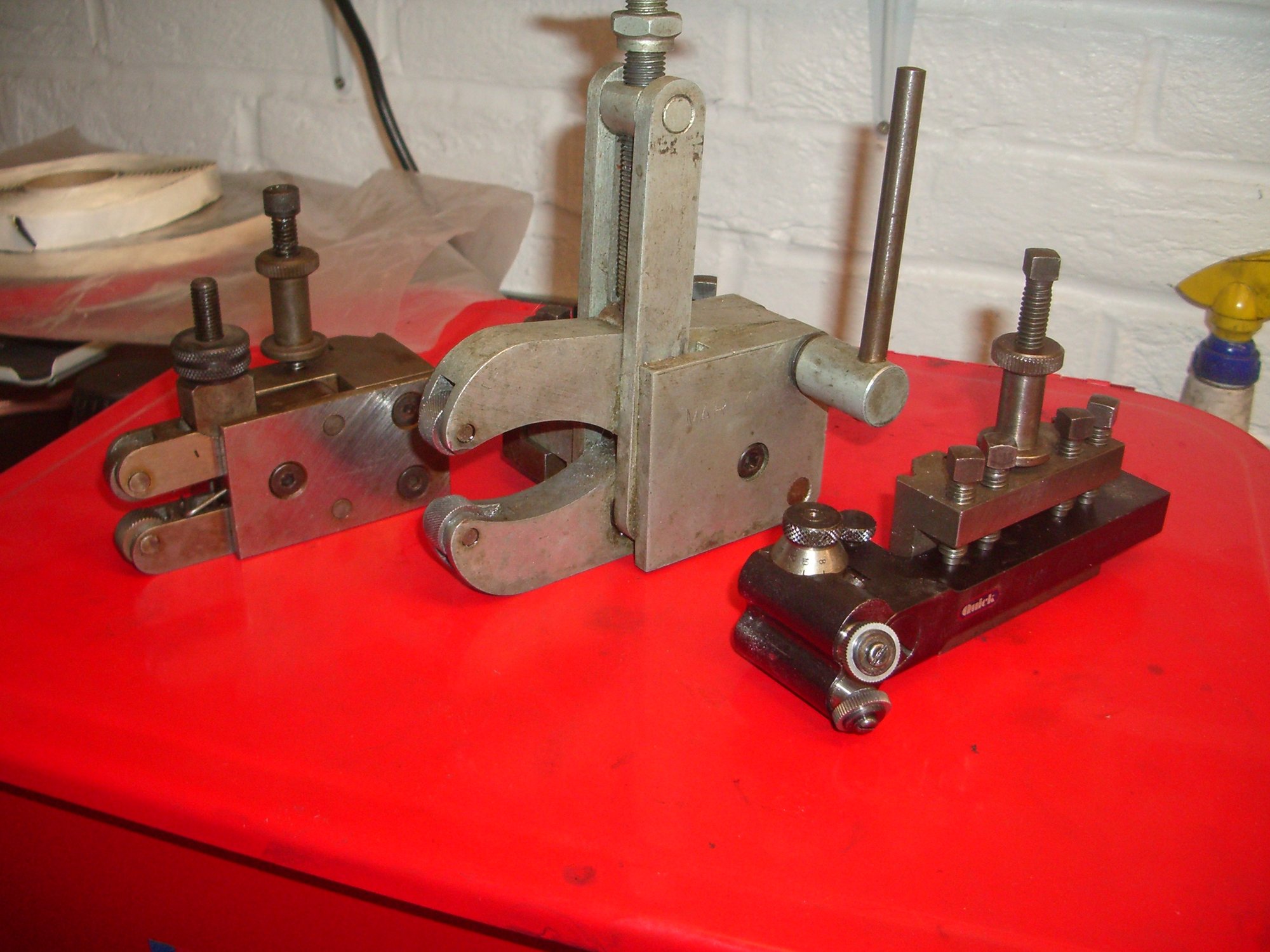

I'm sure I've posted this before, left to right, good, better, best.

The one on the right, you dial in the approximate diameter and the angle knurling wheels cut material rather than trying to cold form it, very little pressure required.

The one on the right, you dial in the approximate diameter and the angle knurling wheels cut material rather than trying to cold form it, very little pressure required.

I used to to a bit of knurling when I had my lathe, came in handy for anything that you need to grab or twist, or just to snazzy up a part for looks, the clamp style are much better in my opinion than the push type, although I didn't try the angled roller type it seems to me that they might be better still with regards to loading up the lathe.

slim_boy_fat

Member

- Messages

- 29,363

- Location

- Scottish Highlands

The one on the right, you dial in the approximate diameter and the angle knurling wheels cut material rather than trying to cold form it, very little pressure required.

I've just seen the price of one of those....

https://www.ebay.co.uk/i/114149859322

https://www.ebay.co.uk/i/114149859322I'm debating with myself about getting one of these, any thoughts/advice? The attraction of the 'Indian' one would be the spare wheels. But different patterns would surely be available for the Myford one......decisions, decisions.

https://www.ebay.co.uk/itm/KNURLING...e=STRK:MEBIDX:IT&_trksid=p2060353.m1438.l2649

https://www.ebay.co.uk/itm/Spring-L...e=STRK:MEBIDX:IT&_trksid=p2060353.m1438.l2649

slim_boy_fat

Member

- Messages

- 29,363

- Location

- Scottish Highlands

Get a 3 wheel one

Link for an 'example' please? On here I've been reading that the 'pincer' type [technical description there

] are the best as they don't put strain on the lathe/workpiece unless supported by a steady??

] are the best as they don't put strain on the lathe/workpiece unless supported by a steady??

500e

Always buy fire insurance a flood is a hard start

- Messages

- 9,377

- Location

- South West

Dr.Al

Forum Supporter

- Messages

- 2,701

- Location

- Gloucestershire, UK

I read an article in a magazine recently about making your own "cut knurling" tool. I'll see if I can dig it out and will post a reference to it.

The magazine was Model Engineer's Workshop issue 147.

Some more links for other stuff:

https://www.gadgetbuilder.com/Cut_Knurler.html, https://www.gadgetbuilder.com/Cut_Knurler_skp.jpg

https://farm1.static.flickr.com/193/472884443_cd89ce76c9_b.jpg

Kram

Member

- Messages

- 8,375

- Location

- Sussex

That seems too easy to make. The pitch rule still applies with the cut type?

https://www.hommel-keller.de/en/product/zeus-series-241/

https://www.hommel-keller.de/en/product/zeus-series-241-kopie/

https://www.hommel-keller.de/en/product/zeus-series-241/

https://www.hommel-keller.de/en/product/zeus-series-241-kopie/

Last edited:

Brad93

Member

- Messages

- 19,429

- Location

- Essex, United Kingdom

As and when.

For example:

View attachment 221653

Not very good, but it works. I should have used a finer knurl.

And

View attachment 221654

To make these. It was easier to do all of the knurling in one go

View attachment 221655

nice job on those. Assume they’re two hole pins for pipe flanges?

mrsbruce

Member

- Messages

- 1,969

- Location

- Livingston, Scotland

I tried to watch a youtube vid by an American chap on how to do the ‘maths’ for setting up a bit knurling. He had a huge whiteboard behind him which he proceeded to fill with numbers.

None of which I understood.

Which is why I just centre my clamp knurler, switch on the lathe an wing it.

My knurling has many flaws, but my head doesn’t hurt thinking about it.

None of which I understood.

Which is why I just centre my clamp knurler, switch on the lathe an wing it.

My knurling has many flaws, but my head doesn’t hurt thinking about it.

northwest

Searching for the Holy Grail.........

- Messages

- 6,667

- Location

- Manchester UK

I didn't. Everyone assumed a push knurler. Horrible things.

No, they are a parachute for when i turn the piece a couple thou undersize....

I'm sure I've posted this before, left to right, good, better, best.

The one on the right, you dial in the approximate diameter and the angle knurling wheels cut material rather than trying to cold form it, very little pressure required.

I have a couple cut knurls, especially useful when knurling Titanium, if you use a push knurl on Titanium, it just pushes back.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 13,061

- Location

- NE London - UK

nice job on those. Assume they’re two hole pins for pipe flanges?

Thanks Brad. Yes, they are. Made for an ex-member a few years back. They were a right bugger to make. I only had hot-rolled 1" bar that, depending on position, varied in cutting characteristics between plasticine and diamond.

Brad93

Member

- Messages

- 19,429

- Location

- Essex, United Kingdom

Yep. Exactly why I bought mine in from the states, £50 you can’t make a pair for that.Thanks Brad. Yes, they are. Made for an ex-member a few years back. They were a right bugger to make. I only had hot-rolled 1" bar that, depending on position, varied in cutting characteristics between plasticine and diamond.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 13,061

- Location

- NE London - UK

£50 you can’t make a pair for that.

I'd have thought that was an easy enough price to beat.

There must be a manufacturing opportunity for someone with a small capstan and time on their hands.

I did it for free but he was over the moon and I was happy to receive a nice bottle of single malt and a packet of welding rods for my time and effort. Still a damned sight cheap than the imports.