Whilst looking for something yesterday, I came across a whole load of knurling tools that I'd forgotten about. I can't remember the last time I did any knurling in the lathe and this got me wondering if anyone else does any. I've previously avoided them with smaller lathes as felt that the forces involved were detrimental to the lathes bearings but even with my Harrison M300 (which also had a load of knurling tools with it), I've not felt the need to knurl anything. Perhaps I'm just too cautious and might be missing out on another joyous machining pleasure. Anyone a regular knurler?

- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knurling

- Thread starter Mikes

- Start date

eLuSiVeMiTe

Member

- Messages

- 16,383

- Location

- ......

Anything I need to get a grip on will get knurled.Whilst looking for something yesterday, I came across a whole load of knurling tools that I'd forgotten about. I can't remember the last time I did any knurling in the lathe and this got me wondering if anyone else does any. I've previously avoided them with smaller lathes as felt that the forces involved were detrimental to the lathes bearings but even with my Harrison M300 (which also had a load of knurling tools with it), I've not felt the need to knurl anything. Perhaps I'm just too cautious and might be missing out on another joyous machining pleasure. Anyone a regular knurler?

Get a clamp style if your worried

Dr.Al

Forum Supporter

- Messages

- 2,091

- Location

- Gloucestershire, UK

I do quite a bit of knurling as it helps get a good grip. I use a clamp type knurling tool - one of these: https://www.cgtk.co.uk/metalwork/m250/toolholders/images/knurlingtool.jpg - which puts less strain on the bearings than a push type one. Having said that, I think the concerns over bearing strain are more for folk with mini-lathes (which I had when I bought the clamp type tool) or Myfords; I'm sure an M300 would be fine.

I made quite a few brass knurled clamping screws for my bandsaw recently; photos here: https://www.cgtk.co.uk/metalwork/bandsaw/restoration/screws (also on a thread on the forum, but it'll take me longer to find the link to that!)

I've got a knurling calculator on my website for working out a good starting dimension. Interestingly, it is by far the most visited page on my site.

I find you can get a very good result if you measure the knurl pitch (with a piece of paper and a ruler), use the knurling calculator to get a good starting dimension and then keep a low pressure air stream going over the knurl to keep the swarf from building up and graunching up the knurl.

I made quite a few brass knurled clamping screws for my bandsaw recently; photos here: https://www.cgtk.co.uk/metalwork/bandsaw/restoration/screws (also on a thread on the forum, but it'll take me longer to find the link to that!)

I've got a knurling calculator on my website for working out a good starting dimension. Interestingly, it is by far the most visited page on my site.

I find you can get a very good result if you measure the knurl pitch (with a piece of paper and a ruler), use the knurling calculator to get a good starting dimension and then keep a low pressure air stream going over the knurl to keep the swarf from building up and graunching up the knurl.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

As and when.

For example:

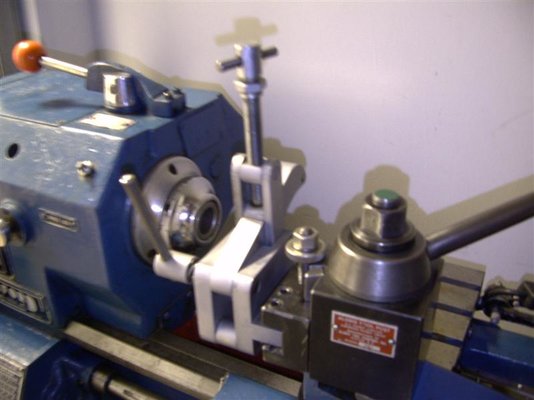

View attachment 221653

Not very good, but it works. I should have used a finer knurl.

And

View attachment 221654

To make these. It was easier to do all of the knurling in one go

View attachment 221655

...and bang goes the myth you cant knurl away from the headstock.

Though it does beg the question, why that end

Dr.Al

Forum Supporter

- Messages

- 2,091

- Location

- Gloucestershire, UK

...and bang goes the myth you cant knurl away from the headstock.

How can you tell he's knurling away from the headstock?

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

How can you tell he's knurling away from the headstock?

true, I’ve only the picture to go on. And why I asked the question

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

Im missing the joke here.

Wisdom is the area to be knurled should be held as close as possible to the headstock, ie chuck, collet, to put the least amount of stress on the headstock bearings.

May be I should have worded the question better.

Wisdom is the area to be knurled should be held as close as possible to the headstock, ie chuck, collet, to put the least amount of stress on the headstock bearings.

May be I should have worded the question better.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

Explain how that works then. I'm knurling with a centre.

Less deflection for one

slim_boy_fat

Forum Supporter

- Messages

- 29,501

- Location

- Scottish Highlands

Get a steady behind the workpiece and you can knurl anywhere along the length.

A knurling tool is on my list of things to get, .....soon..... Plenty on the 'Bay or Banggood [iirc @doubleboost did a review?]

Plenty on the 'Bay or Banggood [iirc @doubleboost did a review?]

A knurling tool is on my list of things to get, .....soon.....

Plenty on the 'Bay or Banggood [iirc @doubleboost did a review?]

Plenty on the 'Bay or Banggood [iirc @doubleboost did a review?]Dr.Al

Forum Supporter

- Messages

- 2,091

- Location

- Gloucestershire, UK

I thought the idea of a clamp knurling tool was that there isn't deflection as it's squeezing the workpiece rather than pushing it to one side.Less deflection for one

Dr.Al

Forum Supporter

- Messages

- 2,091

- Location

- Gloucestershire, UK

I get the feeling you have missed read my initial post was commenting on the fact you have successfully knurled away from the spiny end. I then asked you why you had chosen to do that?

It wasnt a criticism

Ah, I think I also misunderstood - I thought when you said "away from from the headstock", you meant starting at the left and going to the right as opposed to "a long distance from the chuck". The penny has now dropped and the conversation makes more sense to me!

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,986

- Location

- East Yorkshire

I thought the idea of a clamp knurling tool was that there isn't deflection as it's squeezing the workpiece rather than pushing it to one side.

I don’t believe Seadog mention what type he was using, though using either so far from any support is going to cause deflection, either backwards or slipping out of the rollers.

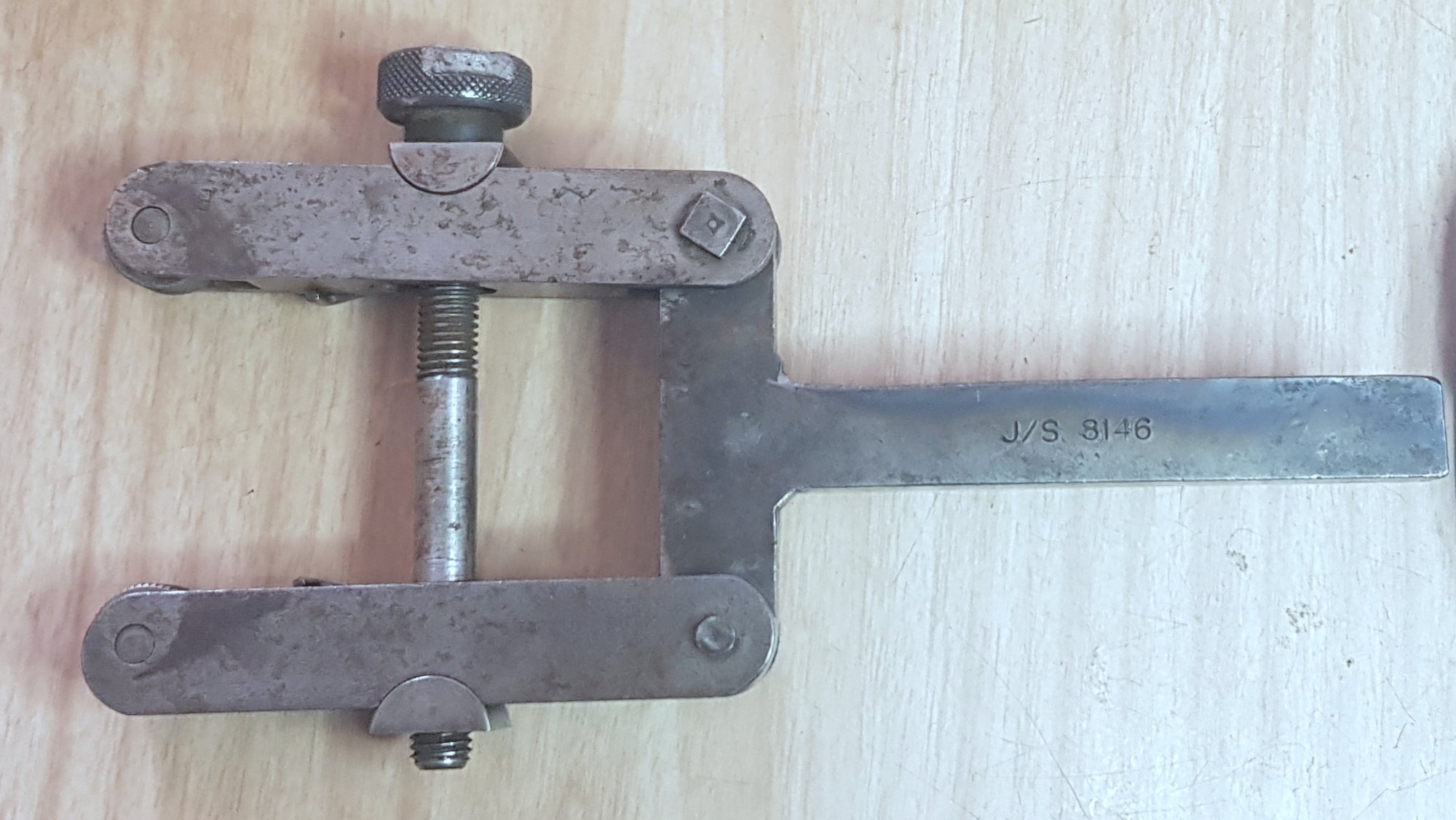

Thanks to all for the responses and shared knowledge. Given this, I'm now not going to shy away from putting on a knurled finish where applicable. Some lovely examples in the photo's showing just how good it can look - very professional. Special thanks to Dr.Al for the link to the knurling calculator. I'd often thought about the need to bet the diameter and pitch correct and now I know. In the box of knurling equipment that came with the Harrison, there is a clamp type as well as the J&S push types so will have a go as soon as the opportunity arises.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 11,449

- Location

- NE London - UK

This is what I use

I didn't. Everyone assumed a push knurler. Horrible things.

I don’t believe Seadog mention what type he was using, though using either so far from any support is going to cause deflection, either backwards or slipping out of the rollers.

I didn't. Everyone assumed a push knurler. Horrible things.

Arc Tourist

Member

- Messages

- 4,672

- Location

- Wales

I like a minimal amount of knurling if its necessary, and agree with " Mikes " and " Seadog "; on the smaller lathes the forces can be a bit much, especially with the old push type tools.

I prefer the clamp type, and have one of the old Marlco tools. The cam lock is a nice feature, but its difficult to find additional knurls available.

.

I prefer the clamp type, and have one of the old Marlco tools. The cam lock is a nice feature, but its difficult to find additional knurls available.

.