Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

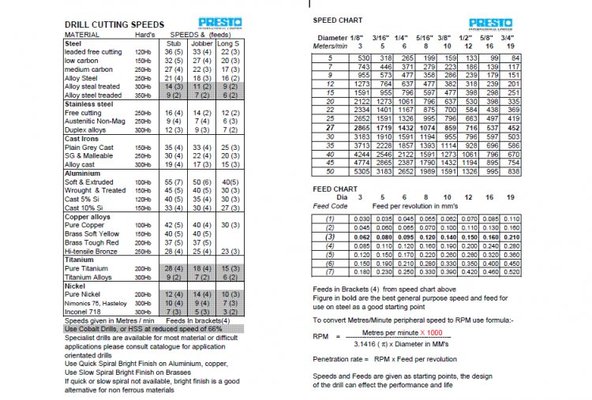

MG David at the bottom of this post is the feed and speed chart for drilling, that I have on the wall next to my drill press. It sounds like you are using far too much speed with your drills and if you are drilling thin material that will also heat up fast transferring heat to the bit. Slow your speed right down as per the chart.

I also recently made a very simple jig for sharpening drills bits on a bench grinder. Couldn't very well be simpler. Gives reasonable results for people like me who haven't done enough drill sharpening to consistantly grind nice points.

All I've done is milled a vee along the side of a block of scrap ally, slightly off-set from center. Then I milled a 2mm step in the block at 59 degrees (half of the 118 point) and milled a corner off at the same angle.

This is how you use it, just hold the drill bit tight in the vee with your fingers and run the stepped edge along your bench grinder tool rest.

The for the secondary relief you just tilt the block and slide the drill forward.

Here is the result - not perfect, but not bad either and drills quite nicely.

Drill speed chart.

I also recently made a very simple jig for sharpening drills bits on a bench grinder. Couldn't very well be simpler. Gives reasonable results for people like me who haven't done enough drill sharpening to consistantly grind nice points.

All I've done is milled a vee along the side of a block of scrap ally, slightly off-set from center. Then I milled a 2mm step in the block at 59 degrees (half of the 118 point) and milled a corner off at the same angle.

This is how you use it, just hold the drill bit tight in the vee with your fingers and run the stepped edge along your bench grinder tool rest.

The for the secondary relief you just tilt the block and slide the drill forward.

Here is the result - not perfect, but not bad either and drills quite nicely.

Drill speed chart.

, I can't sharpen drills to save my life, I'll see if I can get one of those made unless you fancy making another

, I can't sharpen drills to save my life, I'll see if I can get one of those made unless you fancy making another take a look at the drill tip and u will see that it has a flat chissel across the tip . the larger the drill the larger the chissel .so efectively when u are drilling the chissel scrapes away the metal

take a look at the drill tip and u will see that it has a flat chissel across the tip . the larger the drill the larger the chissel .so efectively when u are drilling the chissel scrapes away the metal  small drills have a smaller chissel so will cut quite easy on the cutting tips without scraping . so using a pilot drill 1st will cut the center out then use the larger drill which will be cutting on the flutes not rubbing on the chisel

small drills have a smaller chissel so will cut quite easy on the cutting tips without scraping . so using a pilot drill 1st will cut the center out then use the larger drill which will be cutting on the flutes not rubbing on the chisel