mangocrazy

Italian V-twin nutjob

- Messages

- 1,165

- Location

- Sheffield, UK

Let me add I'm not asking for a freebie - I'm very happy and would expect to pay for any fabrication. I'm currently restoring an old Startrite Mercury pillar drill and one plate is missing and the other is in a pretty poor state. The plates in question are the one that holds the on/off switch to the main body of the drill and the decorative one that should bear the 'Startrite Mercury' emblem on the front section of the drill; this is the missing one.

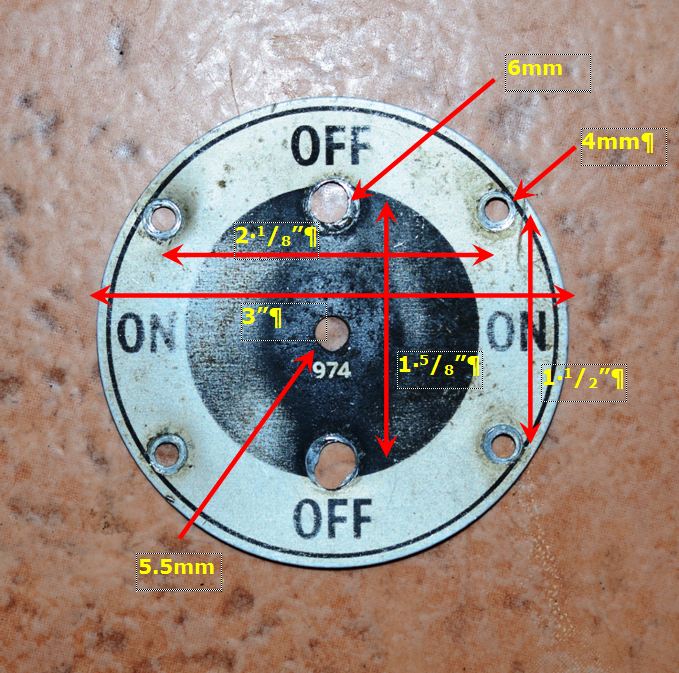

Originally it seems that all the plates on the drill were made out of thin gauge aluminium (less than 1mm). The thinness of the metal has caused the on/off switch plate to suffer somewhat, as it has had to support the switch and endure countless power cycles over the years. A plate in stainless should have a lot more resistance to wear and tear, especially if the sheet gauge was slightly heavier. Here's a picture of the original plate and the relevant measurements.

The overall diameter of the plate is 3 inches, but this could profitably be increased a little to 80mm or so. Apologies for the mix of metric and imperial. Dimensions between fixing centres would obviously have used Imperial measurements when the drill was made, but hole dimensions are (for me) more easily expressed in metric.

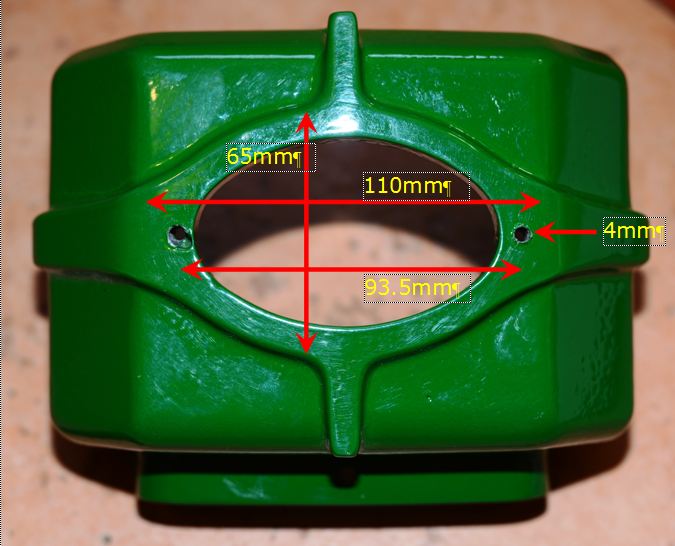

The other plate would (as far as I can tell) be essentially egg-shaped; i.e. an oval of some description. It would bolt onto the front of the cast piece that sits ahead of the front spindle. Hopefully the photo makes it easier to understand.

What isn't evident from the photo is that the front of the cast piece is slightly curved. It curves slightly inward from the centre to the sides, and so here thin gauge sheet would be an advantage, as that would conform better to the slight bend. This piece is purely decorative and only has to support its own weight.

Any help with this is greatly appreciated.

Graham

Originally it seems that all the plates on the drill were made out of thin gauge aluminium (less than 1mm). The thinness of the metal has caused the on/off switch plate to suffer somewhat, as it has had to support the switch and endure countless power cycles over the years. A plate in stainless should have a lot more resistance to wear and tear, especially if the sheet gauge was slightly heavier. Here's a picture of the original plate and the relevant measurements.

The overall diameter of the plate is 3 inches, but this could profitably be increased a little to 80mm or so. Apologies for the mix of metric and imperial. Dimensions between fixing centres would obviously have used Imperial measurements when the drill was made, but hole dimensions are (for me) more easily expressed in metric.

The other plate would (as far as I can tell) be essentially egg-shaped; i.e. an oval of some description. It would bolt onto the front of the cast piece that sits ahead of the front spindle. Hopefully the photo makes it easier to understand.

What isn't evident from the photo is that the front of the cast piece is slightly curved. It curves slightly inward from the centre to the sides, and so here thin gauge sheet would be an advantage, as that would conform better to the slight bend. This piece is purely decorative and only has to support its own weight.

Any help with this is greatly appreciated.

Graham

No probs with the layers. Must get hold of some of that tape.

No probs with the layers. Must get hold of some of that tape. but y'know, I've heard it can be tricky. Especially if you only get one shot at a unique part.

but y'know, I've heard it can be tricky. Especially if you only get one shot at a unique part.