You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hydraulic Press

- Thread starter Brad93

- Start date

Brad93

Member

- Messages

- 19,087

- Location

- Essex, United Kingdom

That's what I'm going for. Hopefully then when I find a 50 ton press this will be easy to move onPicked the right day for wearing all of that spaceman outfit. Going to be better than new - top job.

Brad93

Member

- Messages

- 19,087

- Location

- Essex, United Kingdom

I started reassembling tonight. Annoyingly all the bolts seem to be unf so I can't use new zinc plated bolts. At the minute there's a variety of zinc plated, self colour, covered in paint.

I've ordered new 30T SWL stickers.

Need to order new wire rope and ferrules for the winch.

Tried to get the wheels in motion on the Budenberg pressure gauge, they quoted me earlier in the week but they haven't responded since.

I've ordered new 30T SWL stickers.

Need to order new wire rope and ferrules for the winch.

Tried to get the wheels in motion on the Budenberg pressure gauge, they quoted me earlier in the week but they haven't responded since.

Brad93

Member

- Messages

- 19,087

- Location

- Essex, United Kingdom

That's a right old lump that one. See you can straighten bars in yours because the sides are open, on mine only a small gap at the very top is open. I should of plasma cut some holes in the 3mm sheet at the sides that corresponded with the table heights plus a set of v blocks or something:Looks very familiar - mine was badly fire damaged when I got it

View attachment 305935

View attachment 305936

It's a 60 ton EPCO Brad. The fire was so intense it melted the platen raising motor and hydraulic pump and motor. The cylinder as you can imagine was really badly cooked and took me ages to dismantle and re-build. The platen raises and lowers on four lead screws with sprockets and chain above, the whole lot resting on massive springs arranged so when the press squashes they compress and take the load off the lead screw thrust bearings, but the fire de-tempered the springs. I had to have some custom made from 6mm spring wire (rod!)

Re-build thread here: https://www.madmodder.net/index.php/topic,11437.msg133941.html#msg133941

Re-build thread here: https://www.madmodder.net/index.php/topic,11437.msg133941.html#msg133941

Brad93

Member

- Messages

- 19,087

- Location

- Essex, United Kingdom

EPCO, nice stuff. I bet like their jacks and cranes, that is probably well over-engineered.It's a 60 ton EPCO Brad. The fire was so intense it melted the platen raising motor and hydraulic pump and motor. The cylinder as you can imagine was really badly cooked and took me ages to dismantle and re-build. The platen raises and lowers on four lead screws with sprockets and chain above, the whole lot resting on massive springs arranged so when the press squashes they compress and take the load off the lead screw thrust bearings, but the fire de-tempered the springs. I had to have some custom made from 6mm spring wire (rod!)

Re-build thread here: https://www.madmodder.net/index.php/topic,11437.msg133941.html#msg133941

That system sound much like the system on Pat's Laycock. Much better than the winch mechanism on mine, but obviously a lot more expensive to produce.

Being able to lift the table up and down with the part on it is what got the press its first job the other day. The company doing the work on that gearbox has a 20 ton press (same manufacturer, CAM Equipment but badged BluePoint) but no way of raising the table, and they don't have a forklift to lift the 100kg gearbox up.

Brad93

Member

- Messages

- 19,087

- Location

- Essex, United Kingdom

Thoroughly enjoyed reading through that. I;m also on the lookout for a hydraulic pump of the right type.It's a 60 ton EPCO Brad. The fire was so intense it melted the platen raising motor and hydraulic pump and motor. The cylinder as you can imagine was really badly cooked and took me ages to dismantle and re-build. The platen raises and lowers on four lead screws with sprockets and chain above, the whole lot resting on massive springs arranged so when the press squashes they compress and take the load off the lead screw thrust bearings, but the fire de-tempered the springs. I had to have some custom made from 6mm spring wire (rod!)

Re-build thread here: https://www.madmodder.net/index.php/topic,11437.msg133941.html#msg133941

You wouldn't want to make another of those charts would you? For cash obviously.

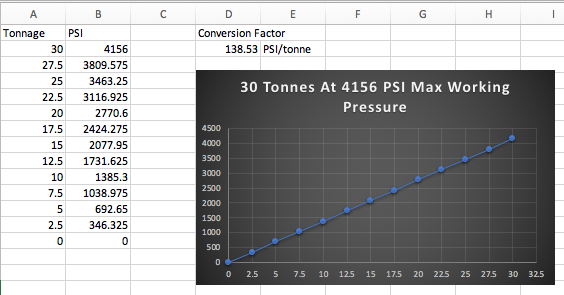

My ram is 30 tonnes at 4156psi. So i guess my chart would look something like.

I'm sure I can sort something out for you Brad. Let me have a few details such as over all size and the chart itself as a DXF file. It wont happen immediately as being school holidays we've grandchildren staying and my time isn't my own

(if you liked the EPCO rebuild thread if you look at the 'New From Old' section of Madmodder you'll see several of my resurrections that you might enjoy https://www.madmodder.net/index.php?board=46.0)

(if you liked the EPCO rebuild thread if you look at the 'New From Old' section of Madmodder you'll see several of my resurrections that you might enjoy https://www.madmodder.net/index.php?board=46.0)

Brad93

Member

- Messages

- 19,087

- Location

- Essex, United Kingdom

There is no rush, I was going to get a sticker printed, but whatever way i envisioned it, it would just look rubbish. I was tempted to have a brass plate done.I'm sure I can sort something out for you Brad. Let me have a few details such as over all size and the chart itself as a DXF file. It wont happen immediately as being school holidays we've grandchildren staying an my time isn't my own

Brad93

Member

- Messages

- 19,087

- Location

- Essex, United Kingdom

Press is painted and back together, helped @Milkybars press his loco wheels onto their axles today, with the help of a hot plate it was a doddle. Still need some bottom plates With holes though. We made a temporary solution but not thick enough.

The ram needs shimming to align it with the bed/table. Due to the fact the whole thing is ****** from factory, it doesn't quite press square.

The ram needs shimming to align it with the bed/table. Due to the fact the whole thing is ****** from factory, it doesn't quite press square.

Brad93

Member

- Messages

- 19,087

- Location

- Essex, United Kingdom

Well something odd is occurring with the press.

I pumped the ram all the way down yesterday to see how square it is to the table. When it reached the bottom (I assume) if it's travel, a big old squirt of hydraulic oil came out of the fitting on the side of the ram. This fitting had a tube that returned to the tank, but I need to put some new hose on it.

Now every time you pump the ram down you get a slight dribble from this fitting in the side of the ram. It wasn't doing it the other day when we was pressing @Milkybars wheels, so I've obviously damaged a seal taking it to the end of its stroke,

any ideas?

I pumped the ram all the way down yesterday to see how square it is to the table. When it reached the bottom (I assume) if it's travel, a big old squirt of hydraulic oil came out of the fitting on the side of the ram. This fitting had a tube that returned to the tank, but I need to put some new hose on it.

Now every time you pump the ram down you get a slight dribble from this fitting in the side of the ram. It wasn't doing it the other day when we was pressing @Milkybars wheels, so I've obviously damaged a seal taking it to the end of its stroke,

any ideas?

Munkul

Jack of some trades, Master of none

- Messages

- 7,772

- Location

- Cumbria

It'll be the rod-side relief hole fitting? Like you say, the rod seal must be leaking slightly and every time you use it, some will pass to the rod side and come out of the hole. The original design was sensible as they know at some point you'll have a leaky ram seal, so they piped it as a specific relief line back to the tank. Most setups aren't this sensible, they just leak oil

It won't have done it the other day because you had it all apart, so the oil will have dribbled out earlier and you were just topping it back up to the fitting height in the cylinder

It won't have done it the other day because you had it all apart, so the oil will have dribbled out earlier and you were just topping it back up to the fitting height in the cylinder

Not been following the thread but that ram is piston down so any oil leaking past is going to sit there until you go full stroke, then pee out of the overflow pipe. There will always be oil on top of the piston, so is going to leak past say, a scratch, all the time, even with no pressure on, in fact maybee more so, as the seals are designed to swell and seal harder with pressure behind them.

Well something odd is occurring with the press.

I pumped the ram all the way down yesterday to see how square it is to the table. When it reached the bottom (I assume) if it's travel, a big old squirt of hydraulic oil came out of the fitting on the side of the ram. This fitting had a tube that returned to the tank, but I need to put some new hose on it.

Now every time you pump the ram down you get a slight dribble from this fitting in the side of the ram. It wasn't doing it the other day when we was pressing @Milkybars wheels, so I've obviously damaged a seal taking it to the end of its stroke,

any ideas?

Probably obvious Brad but try it under load, if it squirts out you know it’s a seal. All I can think of is there’s a section at the end of the stroke with a bit of corrosion on it, or even a step and it’s caught the seal maybe?

Edited to say @Munkul may well be correct and it was damaged to begin with and the fluid has dribbled past while it’s been sat.