My Old Landy

Engineering Mayhem

- Messages

- 3,491

- Location

- North Lincs

That's not good. I've not personally had that so I don't know what you would need to alter to stop the initial squash being so hard.

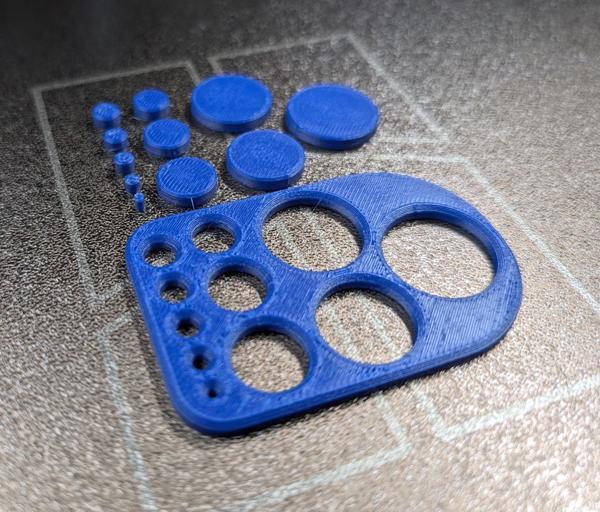

Try printing a Dummy 13 they are a great model and do test the printer on little things.And I haven’t yet printed anything with such a small footprint.

Should do but if it doesnt then a liggt dusting of 3Dlac will solve any troubles.Smooth should work ok without glue. I've been using the patterned smooth plates, PETG and it sticks well to them. Lots to choose from on amazon, they all come from China and near enough the same - some might not have logos and need build plate detection turned off, which I couldnt really care about.

I'd be interested fo know, does the H2D default to 55 degrees bed for PLA? My brothers A1 sets to 65c. I had some issues at 55 but none above 60c.

Interesting, what is the blue/grey?It's much more fussy about filament than the Prusa was. It prints the Bambu stuff really well, but the blue/grey coloured stuff I print with a lot seems to cause it all manner of issues.

Tolerances do seem to vary quite a bit across printers. I printed a DeWalt battery holder the other day. I believe @Onoff? had posted the link, a while back, & said he'd had to print it at 102% for a good fit. I did it at that size, & it was a sloppy fit. Original size is perfect, (printed two more at 100% & 101%), according to the chap I printed it for.

Interesting, what is the blue/grey?

Tollerances will depend on shrinkage, the filament and settings used for it, and likely to vary again with printing speed.

That raises the question, do you model the part with clearances in mind or exactly to size, then scale it. Some features may need different scaling..?

I have some of their other petg and it prints without issues, but particually your one and some colours of their ABS have some bad reviews. I am thinking they might have had bad batches but it doesnt explain why your prussa was ok with it. Try printing it on 50% silent speed, perhaps it cant flow well e ough for higher speedsThis stuff: https://amzn.to/4rsXm6J

I have some of their other petg and it prints without issues, but particually your one and some colours of their ABS have some bad reviews. I am thinking they might have had bad batches but it doesnt explain why your prussa was ok with it.

Try printing it on 50% silent speed, perhaps it cant flow well e ough for higher speeds

Try some Esun?

thats not normal! Temperatures might be off? sensors loose connection?

thats not normal! Temperatures might be off? sensors loose connection?Please do you have a photo of some parts with the satin finish plate? I might be tempted to get one for the P2S. The textured does leave it a bit rough.

You certainly have some issue with the petg settings or printer calibrationthats not normal! Temperatures might be off? sensors loose connection?

What temperatures are you using for bed and nozzle on petg? Bed looks 20c too hot and nozzle 20c too cold!

80c bed and 260c nozzle works well here. I've not used Bambu's filament as its expensive, but four different brands and 10 (part) rolls of petg without issues.

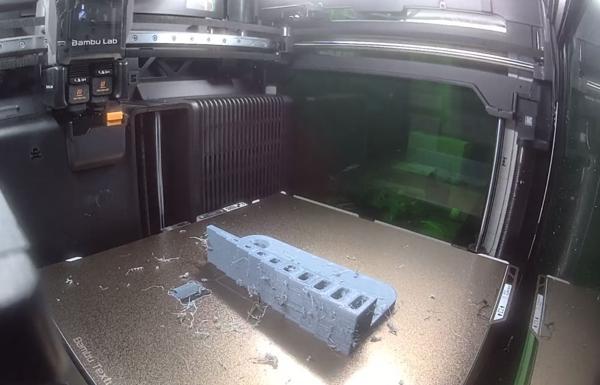

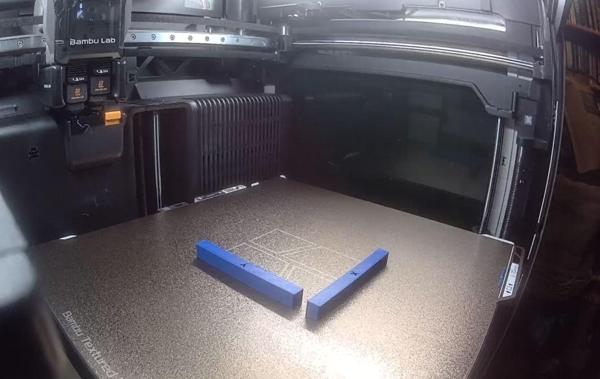

I did have some issue with ABS, perhaps worsened by a fireware update that adjusted the fan settings. The side fan blows direct at the bed, chilling the part. Horrible first layers. I added this white 45 degree deflector yesterday and seems to fix that.