EddyP

Member

- Messages

- 726

- Location

- Northants

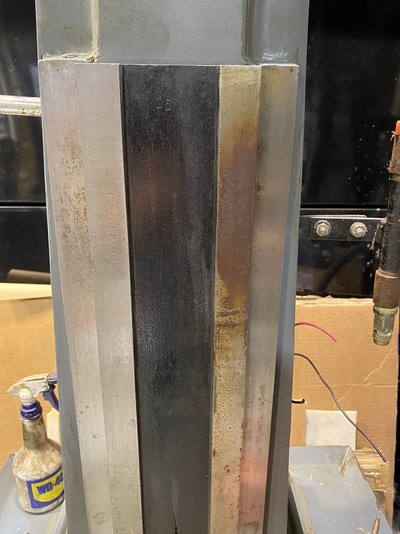

I’ve been after a mill for a couple of months and annoyingly missed out on some great deals on eBay but I finally managed to find myself one, went to pick it up the other night but haven’t done much else yet as can’t lift for a week due to having a lumber puncture yesterday. Itching to get it in the workshop and start cleaning it up.

Needs a bit of TLC and rewiring then would like to fit a DRO. There’s quite a bit of backlash in the X and Y axis, looks like it’s the nuts loose rather than play in the thread though.

Wondering if I should repaint it before reassembly....

Need to have a little move around for it to fit here in its new home.

Needs a bit of TLC and rewiring then would like to fit a DRO. There’s quite a bit of backlash in the X and Y axis, looks like it’s the nuts loose rather than play in the thread though.

Wondering if I should repaint it before reassembly....

Need to have a little move around for it to fit here in its new home.