You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Review EWM Picomig 180 Puls - Single Phase

- Thread starter hotponyshoes

- Start date

hotponyshoes

Member

- Messages

- 7,940

- Location

- Somerset. Uk

I have just been keeping the setting for the thickness of the material so far..

Tried going down to 1.5mm sheet butt weld and that worked so went down to some 1.2 which I managed to get a fillet on ok. (Ish)

The welds loom better in the flesh than they do in the photos. Honest.

Found some 3mm and did (bottom to top) butt then a lapp. Then stuck the bit of 1.5 that I did the butt weld on to the 3mm. (I turned the welder down to 2.2mm for this (that was a guess which seemed ok)

Then tried inside and outside corners on 3mm again

Tried going down to 1.5mm sheet butt weld and that worked so went down to some 1.2 which I managed to get a fillet on ok. (Ish)

The welds loom better in the flesh than they do in the photos. Honest.

Found some 3mm and did (bottom to top) butt then a lapp. Then stuck the bit of 1.5 that I did the butt weld on to the 3mm. (I turned the welder down to 2.2mm for this (that was a guess which seemed ok)

Then tried inside and outside corners on 3mm again

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Much nicer

I know what you mean about the camera, sometimes I take a snap of a lovely weld and when I look at the pic I can't believe how bad it looks, so much so I have to go back and look atthe weld again to make sure I wasn't imagining it

I know what you mean about the camera, sometimes I take a snap of a lovely weld and when I look at the pic I can't believe how bad it looks, so much so I have to go back and look atthe weld again to make sure I wasn't imagining it

hotponyshoes

Member

- Messages

- 7,940

- Location

- Somerset. Uk

Another couple of notes,

One press on the trigger does bring it out of stand-by.

Adjusting the dynamic done on the top left display. This one seems to cover all the adjustments that I have found so far (still not worked out how to change the pulse settings etc, it's possible these might appear if I put it into manual mode?)

One odd thing, if I change the JOB, I press the JOB button and the top left display then displays the current job number (this stays displayed on the lower display as well) I then select the new job number on the top left display.

When this times out back to the welding display, the bottom display updates with the new job number.

So, the right & lower displays seem to be dedicated to volts and JOB only.

One press on the trigger does bring it out of stand-by.

Adjusting the dynamic done on the top left display. This one seems to cover all the adjustments that I have found so far (still not worked out how to change the pulse settings etc, it's possible these might appear if I put it into manual mode?)

One odd thing, if I change the JOB, I press the JOB button and the top left display then displays the current job number (this stays displayed on the lower display as well) I then select the new job number on the top left display.

When this times out back to the welding display, the bottom display updates with the new job number.

So, the right & lower displays seem to be dedicated to volts and JOB only.

hotponyshoes

Member

- Messages

- 7,940

- Location

- Somerset. Uk

That's why I can't find it then!

The pulse seems to be pretty rapid, I thought I might turn it down a bit to get the stack of dimes, maybe I just need to move a bit faster!

Looking at the welds I have done so far I could do with a cold start feature!

Crater fill would be nice but I can cope with that manually.

How about the arcForce, arcRoot, etc.

Are they something I select or just something added in to certain Job's?

The pulse seems to be pretty rapid, I thought I might turn it down a bit to get the stack of dimes, maybe I just need to move a bit faster!

Looking at the welds I have done so far I could do with a cold start feature!

Crater fill would be nice but I can cope with that manually.

How about the arcForce, arcRoot, etc.

Are they something I select or just something added in to certain Job's?

hotponyshoes

Member

- Messages

- 7,940

- Location

- Somerset. Uk

Looking at my photos again, I think I need to work on going in a straight line first before worrying about the other settings too much!

Hotstart is listed in the book but I think that's for mma.

Hotstart is listed in the book but I think that's for mma.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I think you are thinking of double pulse, that is where you get a higher current pulse then drop to a lower current pulse then back to high etc etc

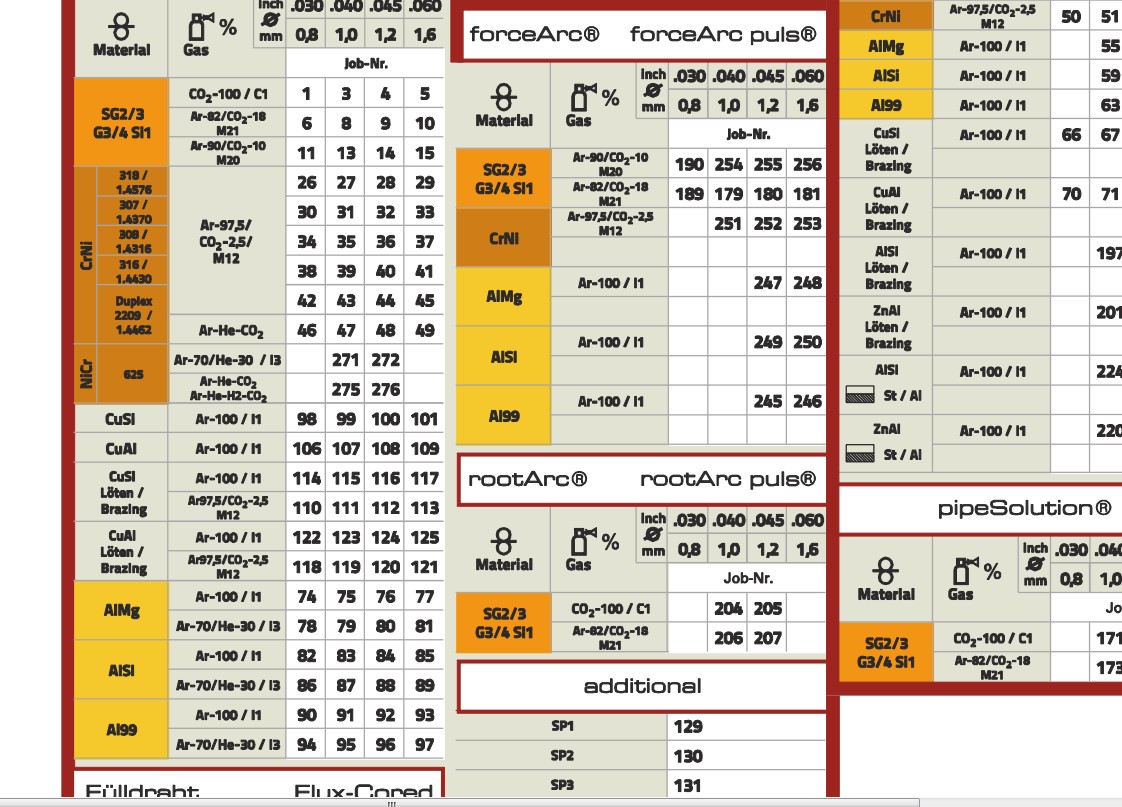

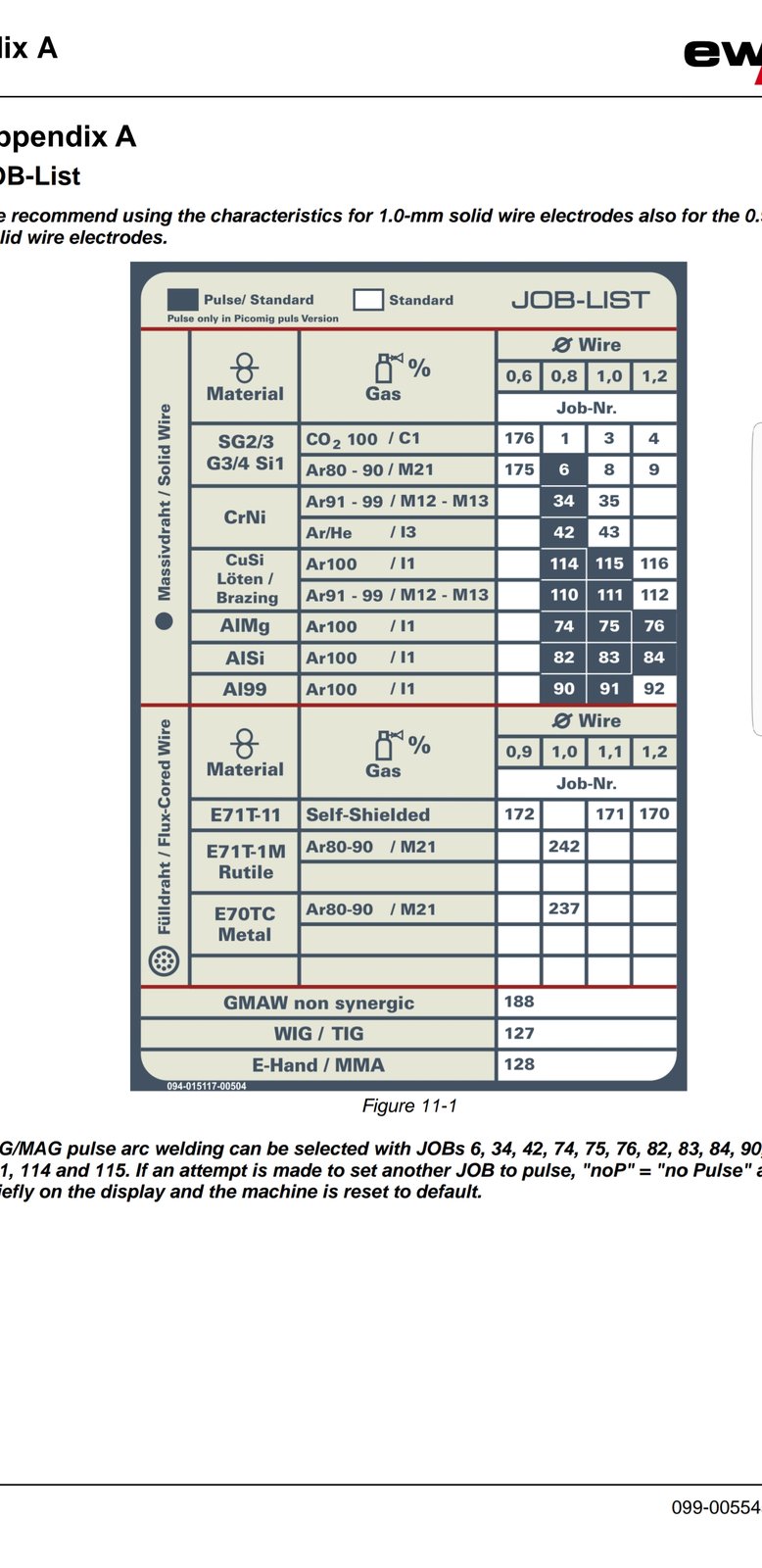

ForceArc etc will just be chosen by selecting the relevant job number, see mine below.

Job 247 being 1.2 AlMg in ForceArc

ForceArc etc will just be chosen by selecting the relevant job number, see mine below.

Job 247 being 1.2 AlMg in ForceArc

hotponyshoes

Member

- Messages

- 7,940

- Location

- Somerset. Uk

Maybe. On my tig i turn pulse on, then set the pulse frequency. I turn this down so I can get nice even drops of filler. (As I have no skills)

I can't see anything like that on my job sticker?

It's in the specs though

I can't see anything like that on my job sticker?

It's in the specs though

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Will have to wait for @Jim Davey to say whether the Pico you have has ForceArc or not.

hotponyshoes

Member

- Messages

- 7,940

- Location

- Somerset. Uk

I will have to twiddle the knob and see if there are any jobs in there that are not on the sticker..

Is the force arc etc usefull?

I have just noticed that the spot time and interval time can be set down to 0.1 of a second which might be one way of getting nice even dimes?

Is the force arc etc usefull?

I have just noticed that the spot time and interval time can be set down to 0.1 of a second which might be one way of getting nice even dimes?

hotponyshoes

Member

- Messages

- 7,940

- Location

- Somerset. Uk

I have checked the job list and it's only giving me the ones that are on the sticker?

I will drop ewm an email and see what is going on with the missing features.

I have had a bit more practice at 'cosmetic' welding but not quite got there yet! Ran out of scraps today so will have to cut some more up and have another go!

My welds are still a bit smoother/flatter than I would like (trying to achieve the stacked look). If I was using tig I would add more filler at each dab it stack it up a bit, with the synergic, I turn the wire speed up which also turns the amps up so I just end up traveling faster rather than building the weld top up.

I tried JOB188 (manual / non-synergic) but it will not let me turn pulse on at all when in manual? Is that normal?

I will drop ewm an email and see what is going on with the missing features.

I have had a bit more practice at 'cosmetic' welding but not quite got there yet! Ran out of scraps today so will have to cut some more up and have another go!

My welds are still a bit smoother/flatter than I would like (trying to achieve the stacked look). If I was using tig I would add more filler at each dab it stack it up a bit, with the synergic, I turn the wire speed up which also turns the amps up so I just end up traveling faster rather than building the weld top up.

I tried JOB188 (manual / non-synergic) but it will not let me turn pulse on at all when in manual? Is that normal?

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Not sure regarding manual mode, never used it on the 355 and don't even think the 330 has it.

As you only have single pulse then torch manipulation will be the only way to get any real pattern in the weld. Try either back/forth or small circular movements, think it most likely circular movements I did in the previous pic of the monitor stands. Then again I just vary things as I progress as I watch the puddle and can change between tecniques as I go

To get the stacked look you really need double pulse I would say.

As you only have single pulse then torch manipulation will be the only way to get any real pattern in the weld. Try either back/forth or small circular movements, think it most likely circular movements I did in the previous pic of the monitor stands. Then again I just vary things as I progress as I watch the puddle and can change between tecniques as I go

To get the stacked look you really need double pulse I would say.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I would call that the rippled lookYou can get the stacked look with a slight back and forth movement as you travel.

This is the pic I posted in the other thread of single pulse.

And this was double pulse which I would call the stacked look

This was also double pulse but with a quick move between pulses.

6 milli billi

Member

- Messages

- 118

Hi all, just wanted to say this really is a thorough and excellent review of our Picomig 180 Puls machine! Thank you to Hotponyshoes for taking the time to share his experiences, and to all those that have added comments and advice! I will send a link to this to our factory in Germany, as i am sure they will be very interested in all of the valid points you have made. I can confirm that the 180/ 185 machines do not have ForceArc/ or RootArc options, these processes are only available on the 415v Picomig 355 variants. I agree with your point ref the guide tube being part of the conversion set, however the only reason I can see is that in the past where we had conversion sets that could be used on different machines, they all have different distances from the euro fitting to the rollers, therefore we would have several additional part numbers to stock, with every conversion set for each model. However in the case of the 180, this is now the only machine that is using this particular wire feed set up, so we would only have 1 size. I will mention to the relevant people. If there is anything else i can help with just let me know. Happy New Year to all!!