RobCox

Member

- Messages

- 545

- Location

- Cambridge, UK

This arrived courtesy of DPD the other day:

I bought it off @skotl. My hope was that as it is a 3" dividing head, rather than the 7" I already have, it would be a bit smaller and fit on the shaper a bit easier.

Wrong! Having taken it to bits to start a full refurb, I offered up the base casting to the 7" mounted on the shaper. Turns out that the head that this belongs to

is exactly the same as this

Swing being the difference, oh and ignoring the extra 1/2" . Never mind, it's going to get the full treatment before I sell it I guess. Don't need two.

. Never mind, it's going to get the full treatment before I sell it I guess. Don't need two.

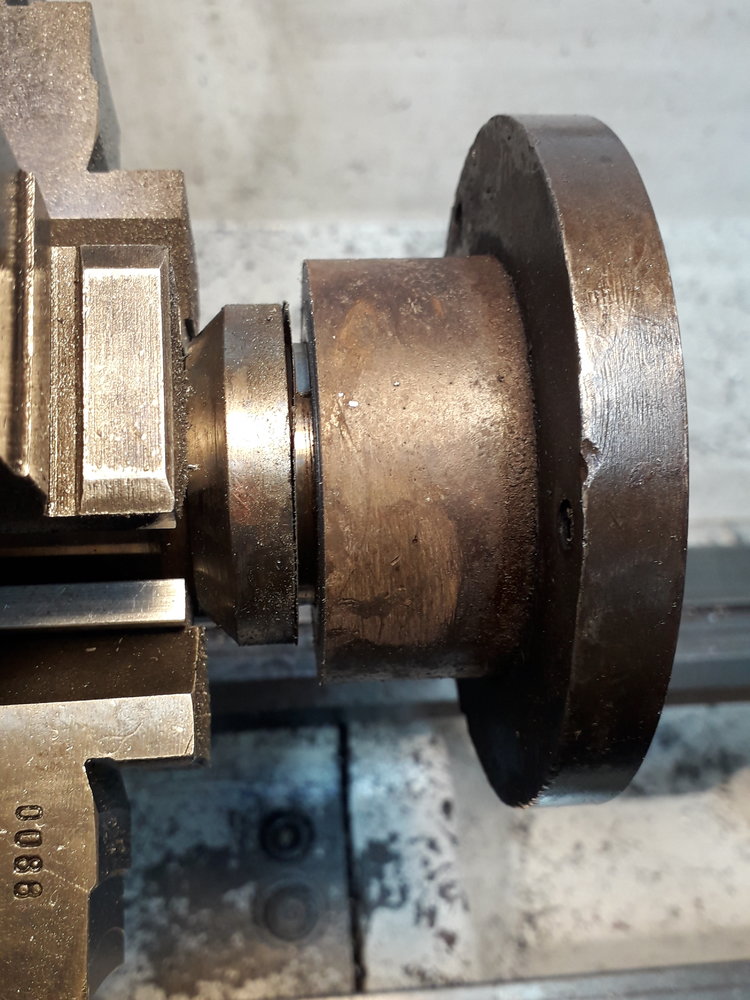

So work on it has begun. I stripped it to bits, except that the chuck was stuck fast to the spindle, really tight, even after cooking it with a propane torch, gripping the spindle in my bench vice and giving the backplate a few whacks on some screws placed in the chuck mounting holes (until one screw sheared off and I gave up). I resorted to the lathe, parting off the backplate close to the spindle:

I managed to avoid the spindle itself and once I'd broken through the backplate came off easily .

.

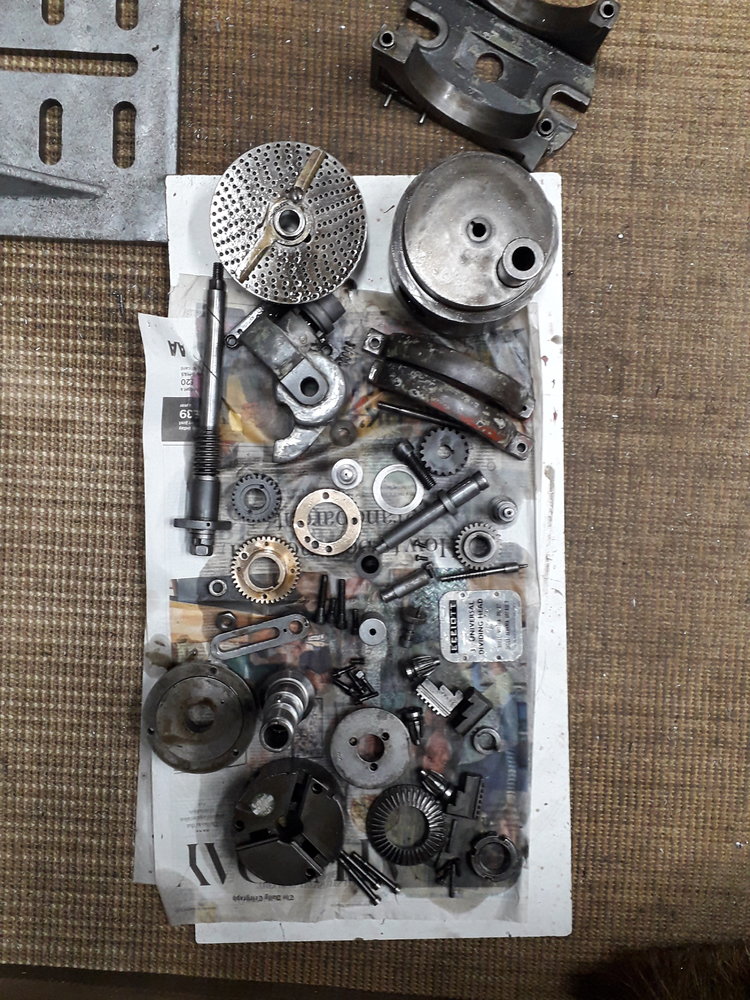

This is the collection of bits after disassembly, after a wire brushing and a bath in white spirit. It was filthy:

I started on the chuck first, which I'll probably keep as its in reasonable nick apart from the "clumsy b*****d" marks. More wire brushing, filing the dings flat (it's not the same shape as an anvil, so why has it been treated like one?), removing burrs and oiled (nearly said "re-oiled", but it hadn't seen any in a long time) it looks like this (with the old screws for comparison):

I bought it off @skotl. My hope was that as it is a 3" dividing head, rather than the 7" I already have, it would be a bit smaller and fit on the shaper a bit easier.

Wrong! Having taken it to bits to start a full refurb, I offered up the base casting to the 7" mounted on the shaper. Turns out that the head that this belongs to

is exactly the same as this

Swing being the difference, oh and ignoring the extra 1/2"

. Never mind, it's going to get the full treatment before I sell it I guess. Don't need two.

. Never mind, it's going to get the full treatment before I sell it I guess. Don't need two.So work on it has begun. I stripped it to bits, except that the chuck was stuck fast to the spindle, really tight, even after cooking it with a propane torch, gripping the spindle in my bench vice and giving the backplate a few whacks on some screws placed in the chuck mounting holes (until one screw sheared off and I gave up). I resorted to the lathe, parting off the backplate close to the spindle:

I managed to avoid the spindle itself and once I'd broken through the backplate came off easily

.

.This is the collection of bits after disassembly, after a wire brushing and a bath in white spirit. It was filthy:

I started on the chuck first, which I'll probably keep as its in reasonable nick apart from the "clumsy b*****d" marks. More wire brushing, filing the dings flat (it's not the same shape as an anvil, so why has it been treated like one?), removing burrs and oiled (nearly said "re-oiled", but it hadn't seen any in a long time) it looks like this (with the old screws for comparison):

. This is impossible to fit with the spindle in place so out it came again. The idler shaft holds the detent which allows or stops the universal feed from moving the dividing plate. This shaft had also received a beating so I skimmed off a couple of thou on the lathe. The anti rotation pin had also been previously sheared off so I drilled it out - breaking a 3.3mm drill in the process. To remove the debris I rotated the shaft 180 degrees and drilled a 2mm hole the other side and used a masonry nail ground down to fit this tiny hole as a punch to drift the detritus out. I then turned a new pin and fitted it:

. This is impossible to fit with the spindle in place so out it came again. The idler shaft holds the detent which allows or stops the universal feed from moving the dividing plate. This shaft had also received a beating so I skimmed off a couple of thou on the lathe. The anti rotation pin had also been previously sheared off so I drilled it out - breaking a 3.3mm drill in the process. To remove the debris I rotated the shaft 180 degrees and drilled a 2mm hole the other side and used a masonry nail ground down to fit this tiny hole as a punch to drift the detritus out. I then turned a new pin and fitted it:

, so I figured I could make one for far less as my time is effectively free, given this is a hobby. I got a chunk of 140mm dia EN1A and took a slice off with my bandsaw. Apparently the capacity of this saw is 125mm for round stock, but it managed this in 3 cuts ok

, so I figured I could make one for far less as my time is effectively free, given this is a hobby. I got a chunk of 140mm dia EN1A and took a slice off with my bandsaw. Apparently the capacity of this saw is 125mm for round stock, but it managed this in 3 cuts ok