eLuSiVeMiTe

Member

- Messages

- 16,383

- Location

- ......

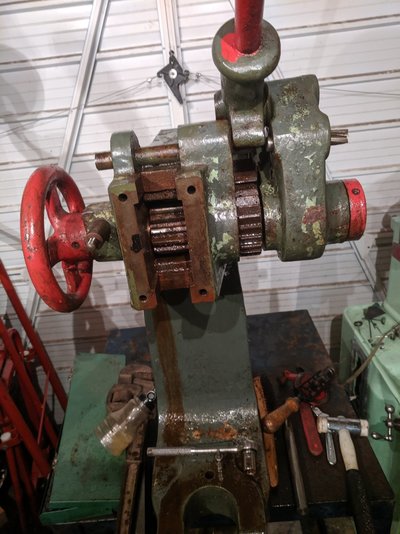

Rather than cluttering up the today I aquired thread I'll post up here.

Gonna need some work to get this back to work.

It's marked as a no.2 but what weight that relates to I couldn't say.

Doing a bit of digging on them it's a compound leverage ratcheting arbour press.

Slide a pin across and double the force.

Here's how I found it.

Apparently been sitting outside for the last 2 years...

Why it was outside will become apparent later.

Gonna need some work to get this back to work.

It's marked as a no.2 but what weight that relates to I couldn't say.

Doing a bit of digging on them it's a compound leverage ratcheting arbour press.

Slide a pin across and double the force.

Here's how I found it.

Apparently been sitting outside for the last 2 years...

Why it was outside will become apparent later.