You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Doris the Dexta renovation

- Thread starter brewdexta

- Start date

I spotted this yesterday so didn't spray the pipes.

Cheers

Andy

Can the pipe go back on reversed to the way in the photo?

brewdexta

The biggest tool in the box

- Messages

- 5,761

- Location

- UK

I think devilbiss do something similar however you buy an adaptor for your spray gun, this allows you to use 3M cup lids, the cups come in 3 sizes, I think. You then buy disposable liners and lids, put a liner in a cup, put in paint and thinners, stick a lid on and drop on the screw on the clamp ring to tighten it. The lid clips onto the gun, as you spray the liner collapses. If you want to stop spraying before using all the paint, take the cup off the adaptor and you get some small caps to clip over the hole to keep the paint fresh. Clean the gun with another cup/liner full of gunwash, and job done. When you want to start again, take off the cap, clip on the paint cup and off you go.

Look up 3M PPS on YouTube

Look up 3M PPS on YouTube

brewdexta

The biggest tool in the box

- Messages

- 5,761

- Location

- UK

Can the pipe go back on reversed to the way in the photo?

I'm a few weekends away from getting the components bolted to the block to find out, but I'll probably replace it with new, my pa left me tube and flaring tools.

I think devilbiss do something similar however you buy an adaptor for your spray gun, this allows you to use 3M cup lids, the cups come in 3 sizes, I think. You then buy disposable liners and lids, put a liner in a cup, put in paint and thinners, stick a lid on and drop on the screw on the clamp ring to tighten it. The lid clips onto the gun, as you spray the liner collapses. If you want to stop spraying before using all the paint, take the cup off the adaptor and you get some small caps to clip over the hole to keep the paint fresh. Clean the gun with another cup/liner full of gunwash, and job done. When you want to start again, take off the cap, clip on the paint cup and off you go.

Look up 3M PPS on YouTube

One thing that is quite interesting is that many videos talk about PPS only being a benefit for paint shops and high volume users. I think the benefits are just as valid if not more so for a low volume user. To be able to mix a small batch, use it over 2-3 days and make no mess is a real benefit. Initial cost seems high but once you've got used to it you wouldn't go back. I hate clean up and I've always said at that point if someone said "Give me £2 and I'll clean the gun" I'd let them do it because as a low user it's likely that one job is your only one that day so to spend £1 on a liner and a lid is a no brainer.It also means you can do all your paint prep in one go because you can have multiple cups ready so no stopping.The only thing I am at odds with is the fact it's more plastic use.

Even though I already have the setup I ended up watching some videos and learnt something. I've only just realised the caps you put on them can be used two ways. I've always put them over the top but I've realised if you are capping while waiting to use them the caps also fit inside the top instead of over which means they are easier to take off.

The other thing I saw is they've now got a new improved version but it doesn't look like it's in the UK yet.

brewdexta

The biggest tool in the box

- Messages

- 5,761

- Location

- UK

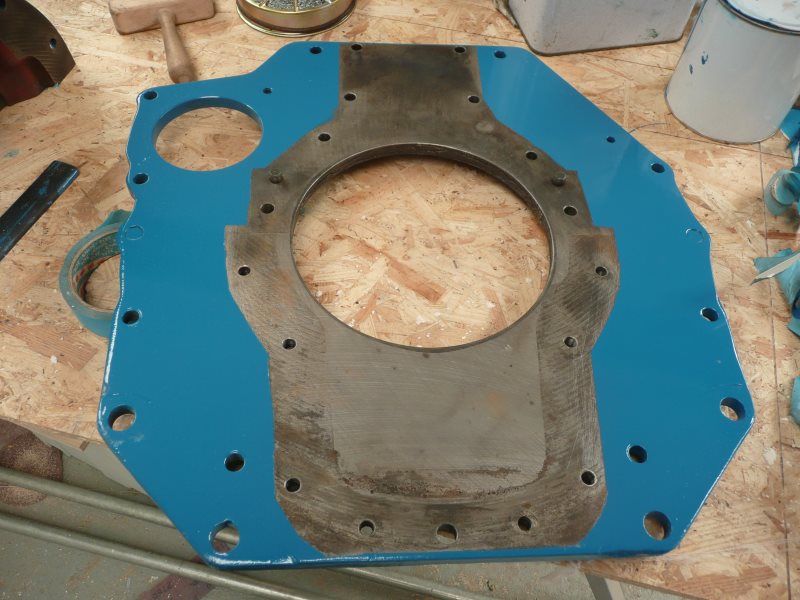

Not much to show for this weeks efforts, mainly putting a second top coat on already painted bits. I'm waiting for the main compressor to be fixed, hopefully tomorrow before painting more bits, apart from the plate between the engine and bell housing.

This was it before most of the gunk was removed, but before masking.

and after the cup brush, sander and final degrease and top coat, on to the other side.

I'm expecting this bit to get a bit of hammer while re-assembling it so will need touching up, I may have to remount the engine on the engine stand to get this on. Not sure yet, I have loads of pictures from dismantling, I shall go back and see if It's worth doing or just get the rest of the bell housing, gearbox and rear axle painted and re-assemble it directly on the chassis. If I put it on before that, it means I can get the sump on and the front axle carrier up in the workshop before lowering it down into the barn to meet the rest of the chassis so that is probably my preference.

Cheers

Andy

This was it before most of the gunk was removed, but before masking.

and after the cup brush, sander and final degrease and top coat, on to the other side.

I'm expecting this bit to get a bit of hammer while re-assembling it so will need touching up, I may have to remount the engine on the engine stand to get this on. Not sure yet, I have loads of pictures from dismantling, I shall go back and see if It's worth doing or just get the rest of the bell housing, gearbox and rear axle painted and re-assemble it directly on the chassis. If I put it on before that, it means I can get the sump on and the front axle carrier up in the workshop before lowering it down into the barn to meet the rest of the chassis so that is probably my preference.

Cheers

Andy

brewdexta

The biggest tool in the box

- Messages

- 5,761

- Location

- UK

Just looking back to 2012 when I first dismantled the engine, blimey, how much space did I have in the workshop! I will put the plate on and remount the engine on the stand. I can then get the flywheel and new clutch on before it meets the rest of the tractor, but using the bolts where the front axle carrier will go at the other end of the engine, if they line up nicely...

The drum kits was an unwanted present from my parents, the kids liked it, try concentrating while a 3 year old is beating the hell out of them!

I had to drill a plate up to mount the engine, the bits that come with the stand just wouldn't work

I forgot how crusty the engine was.

Getting the pulley nut off the crank was a major pain, I had to buy a box spanner in the end.

Cheers

Andy

The drum kits was an unwanted present from my parents, the kids liked it, try concentrating while a 3 year old is beating the hell out of them!

I had to drill a plate up to mount the engine, the bits that come with the stand just wouldn't work

I forgot how crusty the engine was.

Getting the pulley nut off the crank was a major pain, I had to buy a box spanner in the end.

Cheers

Andy

slim_boy_fat

Member

- Messages

- 29,186

- Location

- Scottish Highlands

how much space did I have in the workshop!

A lot more than you currently have, is my bet.

octo0072000

Member

- Messages

- 6,004

- Location

- south yorks

Andy any more updates since 2019 on Doris the Dexta

arther dailey

Member

- Messages

- 7,004

- Location

- England

yup, thats a loverly size shed, and I like you have put the cardboard down to protect floor .Just looking back to 2012 when I first dismantled the engine, blimey, how much space did I have in the workshop! I will put the plate on and remount the engine on the stand. I can then get the flywheel and new clutch on before it meets the rest of the tractor, but using the bolts where the front axle carrier will go at the other end of the engine, if they line up nicely...

View attachment 183860

The drum kits was an unwanted present from my parents, the kids liked it, try concentrating while a 3 year old is beating the hell out of them!

View attachment 183861

I had to drill a plate up to mount the engine, the bits that come with the stand just wouldn't work

View attachment 183862

I forgot how crusty the engine was.

View attachment 183863

Getting the pulley nut off the crank was a major pain, I had to buy a box spanner in the end.

View attachment 183864

Cheers

Andy

brewdexta

The biggest tool in the box

- Messages

- 5,761

- Location

- UK

Andy any more updates since 2019 on Doris the Dexta

I've a couple of small bits here and there but not a lot. I can't remember if I mentioned that I bought some second hand wings, they are original Fomoco rather than the copies I bought originally. The copies fit but they are not the same shape as original.

The guy I bought the second hand ones from has had a go at welding some bits with OA, probably have to take the patches off and start again. Still far better than the ones that were on the tractor when I bought it. That was ages ago. I've resigned myself to delaying this until I've finished the DIY, hopefully start later in the year.

octo0072000

Member

- Messages

- 6,004

- Location

- south yorks

thanks for the update Andy sure you mentioned the wings before

brewdexta

The biggest tool in the box

- Messages

- 5,761

- Location

- UK

I had to get the jet wash out today as the combination of moss, algae and chicken dung around the chicken shed was making it lethal to walk. That was the queue to rescue link box for the dexta, its been outside surrounded by a pile of old pallets and other junk for far too long.

its pretty rough.

Should give me something to work on during the colder months. I jet washed the loose paint and crud off of it, and apart from a few holes and crusty bits, its just about worth sand blasting.

I think this came from a grey fergie originally but was on the Dexta when I bought it. I'll finish it off to match the Dexta, so Empire Blue, but I may do a bit of signwriting on it, as it will be carrying homebrew to the odd car show

I'm going to make a concerted effort next year to get most of the tractor in paint and the engine rebuilt, I think I may have said that a few time before

its pretty rough.

Should give me something to work on during the colder months. I jet washed the loose paint and crud off of it, and apart from a few holes and crusty bits, its just about worth sand blasting.

I think this came from a grey fergie originally but was on the Dexta when I bought it. I'll finish it off to match the Dexta, so Empire Blue, but I may do a bit of signwriting on it, as it will be carrying homebrew to the odd car show

I'm going to make a concerted effort next year to get most of the tractor in paint and the engine rebuilt, I think I may have said that a few time before

Other Daniel

Member

- Messages

- 891

- Location

- France, Charente

You're moving faster than I am with Grandad's SuperDexta.....

brewdexta

The biggest tool in the box

- Messages

- 5,761

- Location

- UK

Correction, I went down to the blasters to have a chat. Price is normally based on minutes of blasting, we ended up negotiating a fixed price. It's more than I thought it was going to cost me, but less than the time based cost,

This is how the rear door came out, as you can see it is well pitted, mainly on the inside. There's a touch of welding to do, then it will be getting two coats of epoxy primer. The inside will eventually be Raptor which will cover some of the pitting. The outside is good enough. eventually the outside will be Empire blue and have my brewery signwriting on it.

Inside very pitted

You can see where it needs a bit of welding.

Outside may be good enough, I'll see what it is like after two coats of epoxy.

Here's the full link box door, size 8 for scale.

Cheers

Andy

This is how the rear door came out, as you can see it is well pitted, mainly on the inside. There's a touch of welding to do, then it will be getting two coats of epoxy primer. The inside will eventually be Raptor which will cover some of the pitting. The outside is good enough. eventually the outside will be Empire blue and have my brewery signwriting on it.

Inside very pitted

You can see where it needs a bit of welding.

Outside may be good enough, I'll see what it is like after two coats of epoxy.

Here's the full link box door, size 8 for scale.

Cheers

Andy

brewdexta

The biggest tool in the box

- Messages

- 5,761

- Location

- UK

Its back from the blaster, quite a bit lighter than when it went by the looks of it

looks like I now have a tractor doily

I don't think its too bad, the remaining metal is quite thick

I'm just checking how many slitting disks I have knocking about. I best check how much argoshield too.

Now nestling in the heated workshop, I'll be tackling the welding this weekend then straight on with the epoxy.

I may leave some perforations as drain holes

looks like I now have a tractor doily

I don't think its too bad, the remaining metal is quite thick

I'm just checking how many slitting disks I have knocking about. I best check how much argoshield too.

Now nestling in the heated workshop, I'll be tackling the welding this weekend then straight on with the epoxy.

I may leave some perforations as drain holes