brewdexta

The biggest tool in the box

- Messages

- 5,737

- Location

- UK

Other bits of this have been covered in this thread about paint and this thread about fixing the front axle

Its tea break time and its cold in the workshop so I'm posting a few pics as I go along.

Today I decided to attack the hydraulics, I took the hydraulic cover off in 2012 so about time I sorted it.

Here's it on the bench upside down after a quick clean off the loose crap.

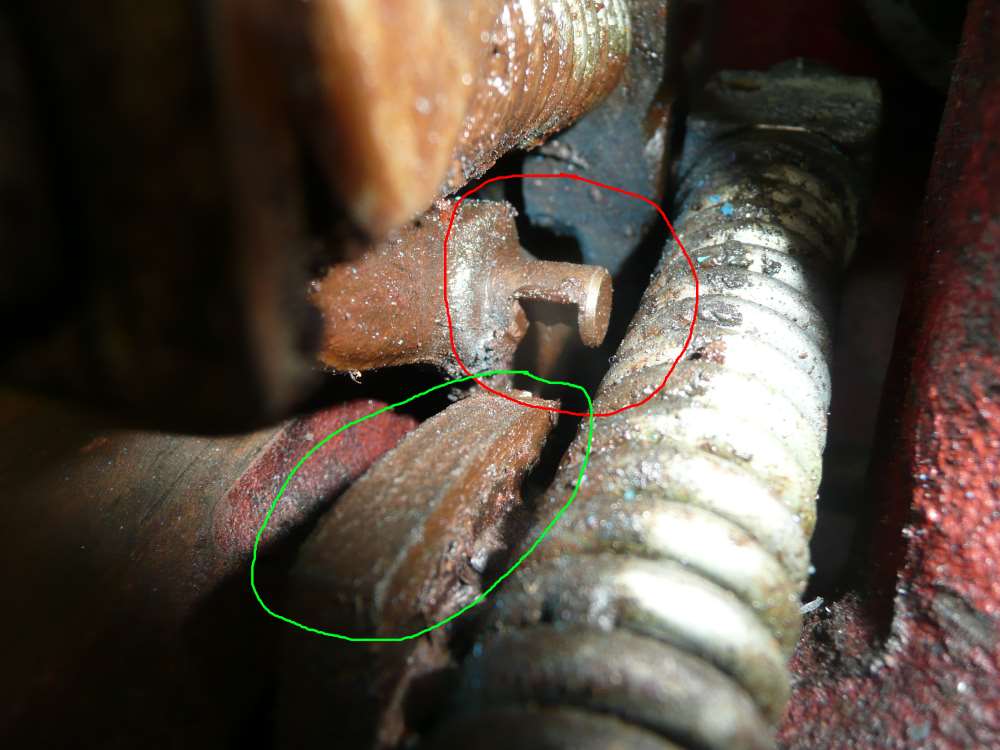

First job is to fix the position control arm stop pin. Its worn and this is the cause of all sorts of maladies if is not fixed. Here it is highlighted in red with the cam it rubs against in green

Its a push fit, I don't want to take the thing completely apart to do this as there is loads of adjustments to redo. Some people have even built them up with weld in situ.

Here's the other side of the pin

And another view of the other side

Its a bit tight so I can see some choice words coming out before I've finished.

And yes I will be clearing out all the dust and grit before it goes back on the tractor

More later

Its tea break time and its cold in the workshop so I'm posting a few pics as I go along.

Today I decided to attack the hydraulics, I took the hydraulic cover off in 2012 so about time I sorted it.

Here's it on the bench upside down after a quick clean off the loose crap.

First job is to fix the position control arm stop pin. Its worn and this is the cause of all sorts of maladies if is not fixed. Here it is highlighted in red with the cam it rubs against in green

Its a push fit, I don't want to take the thing completely apart to do this as there is loads of adjustments to redo. Some people have even built them up with weld in situ.

Here's the other side of the pin

And another view of the other side

Its a bit tight so I can see some choice words coming out before I've finished.

And yes I will be clearing out all the dust and grit before it goes back on the tractor

More later

. I'm letting it soak for a few minutes while I brace myself for the next assault.

. I'm letting it soak for a few minutes while I brace myself for the next assault.