Ali

Member

- Messages

- 1,893

- Location

- Cheshire

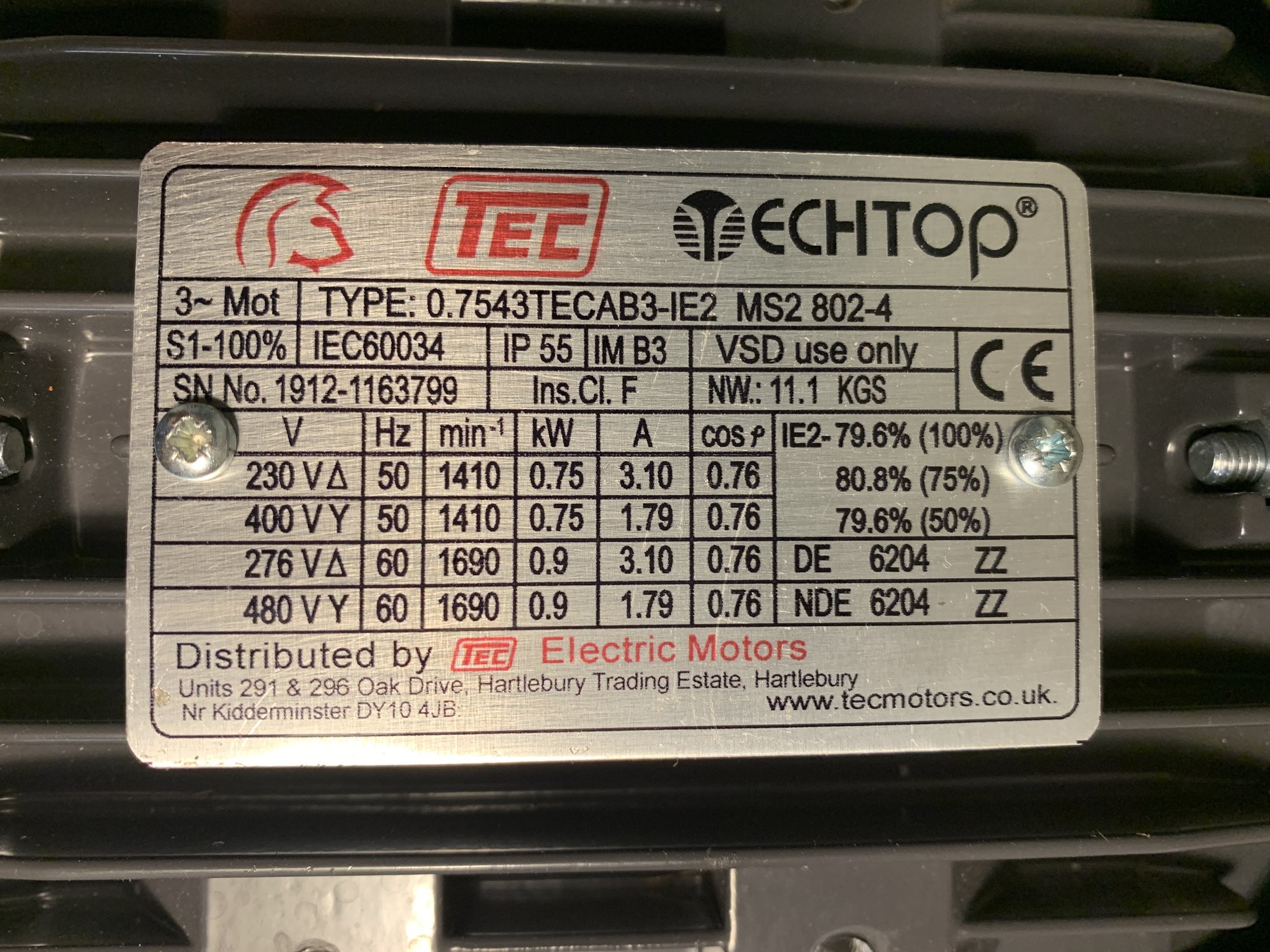

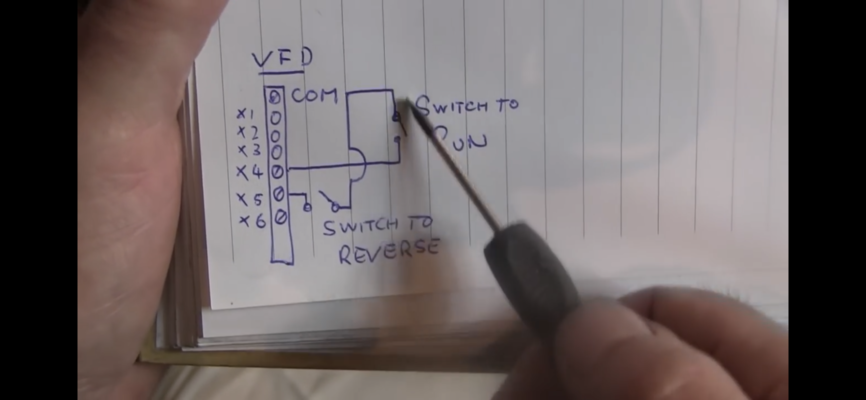

I’m bumbling my way through connecting up a VFD.

Question 1: There is no option in the VFD programming instructions to set the motor type, mine is a 4 pole motor. I’ve searched about and there are instructions for the exact same model VFD showing this as program no. 25. My instructions skip this, 24...26. It feels like I shouldn’t ignore this, advice?

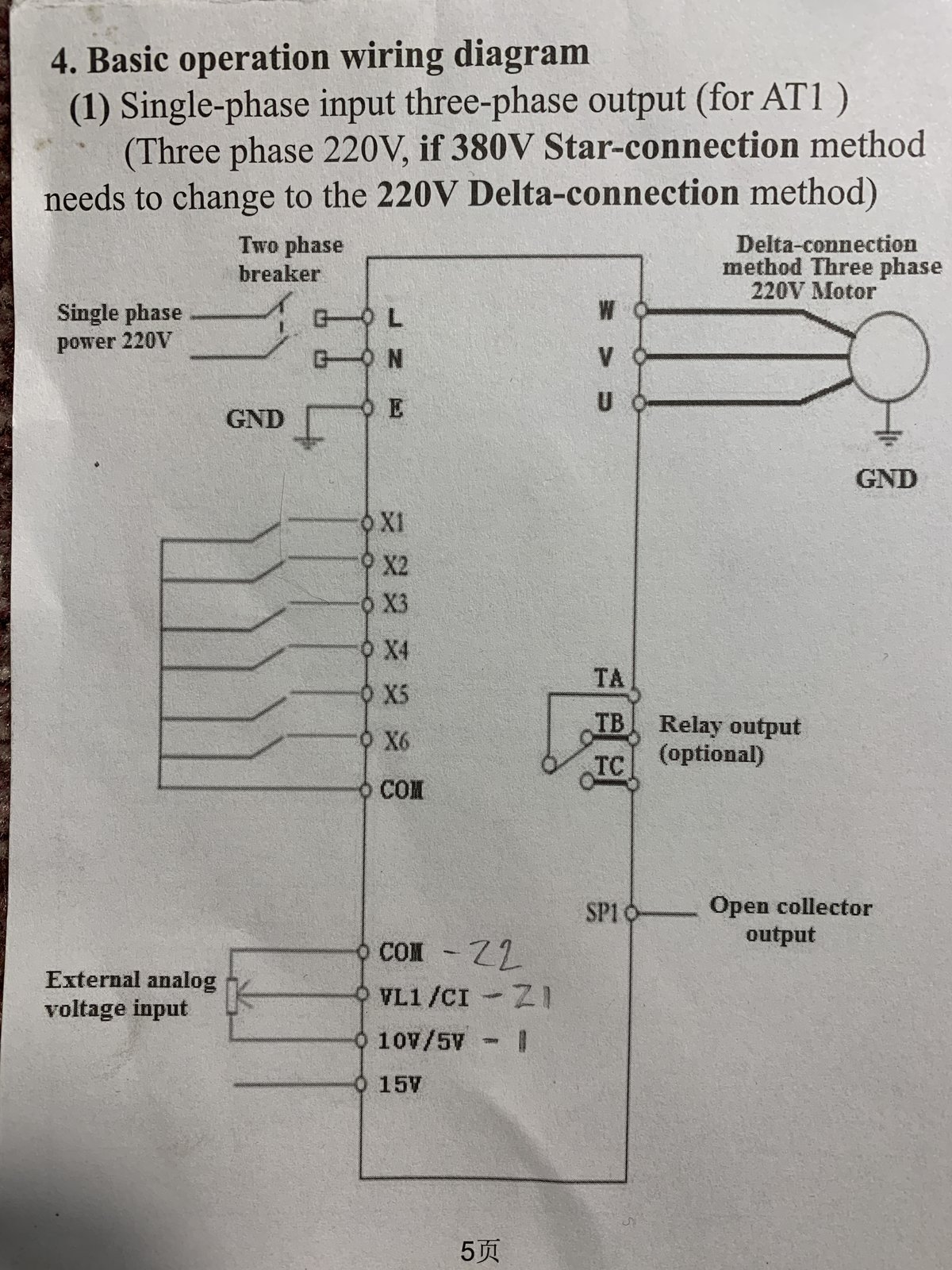

Question 2: The potentiometer I have has terminals marked Z1, 1, Z2.

Is this right? (my pencil markings):

Thanks in advance for any advice making up for my ineptitude.

Question 1: There is no option in the VFD programming instructions to set the motor type, mine is a 4 pole motor. I’ve searched about and there are instructions for the exact same model VFD showing this as program no. 25. My instructions skip this, 24...26. It feels like I shouldn’t ignore this, advice?

Question 2: The potentiometer I have has terminals marked Z1, 1, Z2.

Is this right? (my pencil markings):

Thanks in advance for any advice making up for my ineptitude.

(I'm not joking - looking forward to putting a 3ph motor and a VFD on my lathe

(I'm not joking - looking forward to putting a 3ph motor and a VFD on my lathe  )

)