gaz1

Member

- Messages

- 20,083

- Location

- westyorkshire

ive been around youtube often and have noticed a few builds out there

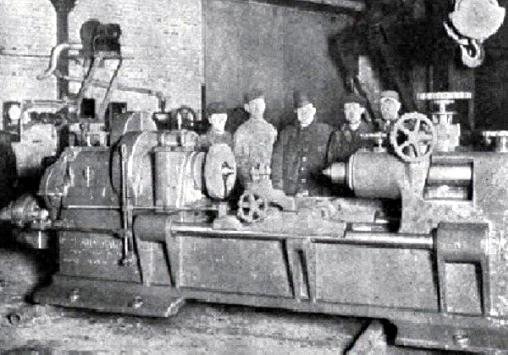

concrete lathe

https://www.engineeringforchange.or...6/02/multimachine-concrete-lathe-ver-1-10.pdf

milling machine

http://opensourcemachinetools.org/w...ploads/2013/12/romig-a-small-bench-miller.pdf

cnc machine

concrete lathe

https://www.engineeringforchange.or...6/02/multimachine-concrete-lathe-ver-1-10.pdf

milling machine

http://opensourcemachinetools.org/w...ploads/2013/12/romig-a-small-bench-miller.pdf

cnc machine

, never heard of epoxy concrete before

, never heard of epoxy concrete before  Thanks for posting

Thanks for posting