dyno-tron

Member

- Messages

- 510

- Location

- Near Chester, UK

There are some projects I want to do which involve cutting lots of tube into small slices so decided that a bandsaw is the best solution which gives the finish I want so:-

Due to missing out on a Cutmax bandsaw on e-bay (it went for more than I was prepared to pay and it was miles away) and the impending lockdown I zoomed out yesterday morning and picked up a H80 Bandsaw from Chester Hobby.

First impressions?

Got it home and unpacked, yep - it is typical low end cheap chinese construction e.g. robust but low precision castings, ancillary pressed steel parts are variable quality and smells of cheap grease :-)

Some pics:-

The frame is decent gauge, robust enough and very sturdy when fully built. Better than my Kity613 wood bandsaw which has a thin pressed sheet steel stand and is a bit floppy.

Pullys are cast iron, adjuster mechanism is basic but works.

The red guard is a bit thin, poor fit and seems like an afterthought, it does the job after I took it off and bent it to make it fit better.

Drive pullys look to be decent size :-)

Warco list 130mm capacity for the same machine, and there is 130mm capacity on this, however - the vice is positioned in such a way to obscure about 40mm.

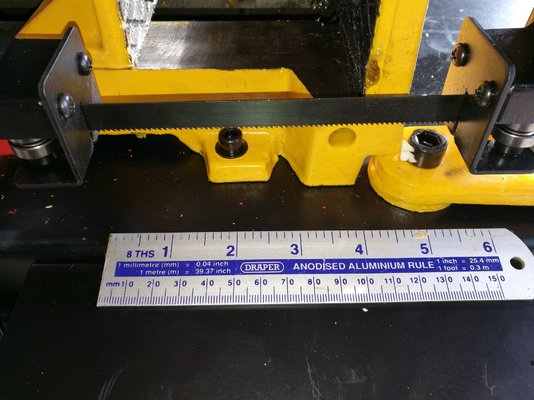

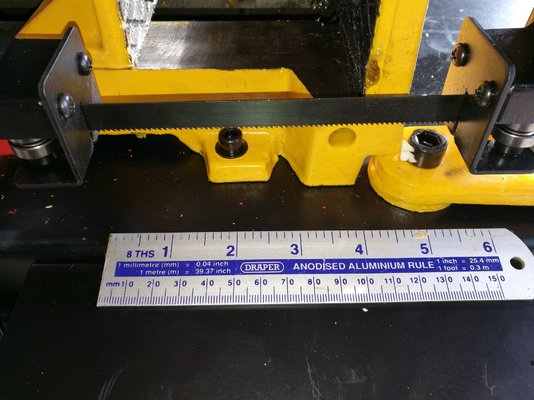

This pic show the rule resting across the saw opening 10mm-140mm

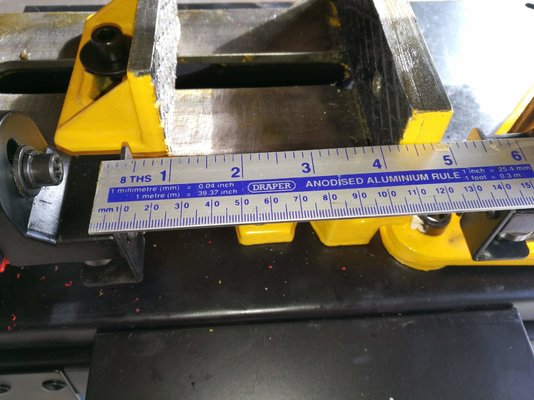

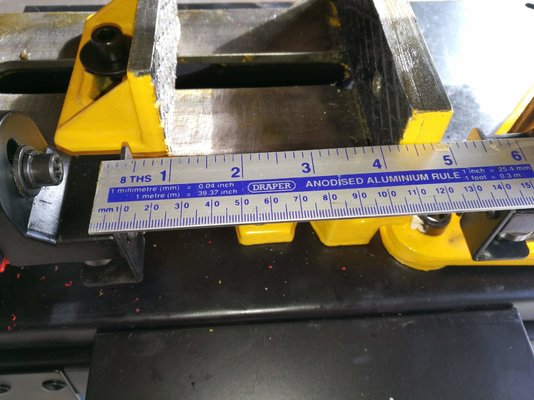

Vise offset is clear in this pic

Vise has plenty of capacity. Maybe it needs a bit of re-engineering/re-positioning to get the full 130mm capacity.

The vise clamp has far too much lift, it needs the travelling nut machining to make it fit better. On the plus side, the acme thread is a good fit so when the nut is machined it should be smooth to use.

The clamp is moved with a plastic handwheel (not shown here) which will most likely break at some point.

Initial conclusion?

The factory really don't need to spend much more to make this into a premium machine, e.g. make blade supports out of a cast/machined pieces instead of pressed, machine it's guide slot instead of relying on the cast recess. Clean up the mould for the main body casting, re-engineer the vise to work better and get the full capacity.

The cheapest Cutmax (the only make I could find that isn't obviously from the same set of blueprints:-) ) is £450, nearly 3 times the price!!

I'm not complaining, I know what I bought and have other Chinese machinery for comparison (mini lathe/Mill/pillar drill/wood lathe etc. So I'm no stranger to this gear and accept there isn't really an option to spend a bit more to get something a bit better.

Will it cut?

That is in the next post!

Due to missing out on a Cutmax bandsaw on e-bay (it went for more than I was prepared to pay and it was miles away) and the impending lockdown I zoomed out yesterday morning and picked up a H80 Bandsaw from Chester Hobby.

First impressions?

Got it home and unpacked, yep - it is typical low end cheap chinese construction e.g. robust but low precision castings, ancillary pressed steel parts are variable quality and smells of cheap grease :-)

Some pics:-

The frame is decent gauge, robust enough and very sturdy when fully built. Better than my Kity613 wood bandsaw which has a thin pressed sheet steel stand and is a bit floppy.

Pullys are cast iron, adjuster mechanism is basic but works.

The red guard is a bit thin, poor fit and seems like an afterthought, it does the job after I took it off and bent it to make it fit better.

Drive pullys look to be decent size :-)

Warco list 130mm capacity for the same machine, and there is 130mm capacity on this, however - the vice is positioned in such a way to obscure about 40mm.

This pic show the rule resting across the saw opening 10mm-140mm

Vise offset is clear in this pic

Vise has plenty of capacity. Maybe it needs a bit of re-engineering/re-positioning to get the full 130mm capacity.

The vise clamp has far too much lift, it needs the travelling nut machining to make it fit better. On the plus side, the acme thread is a good fit so when the nut is machined it should be smooth to use.

The clamp is moved with a plastic handwheel (not shown here) which will most likely break at some point.

Initial conclusion?

The factory really don't need to spend much more to make this into a premium machine, e.g. make blade supports out of a cast/machined pieces instead of pressed, machine it's guide slot instead of relying on the cast recess. Clean up the mould for the main body casting, re-engineer the vise to work better and get the full capacity.

The cheapest Cutmax (the only make I could find that isn't obviously from the same set of blueprints:-) ) is £450, nearly 3 times the price!!

I'm not complaining, I know what I bought and have other Chinese machinery for comparison (mini lathe/Mill/pillar drill/wood lathe etc. So I'm no stranger to this gear and accept there isn't really an option to spend a bit more to get something a bit better.

Will it cut?

That is in the next post!