- Messages

- 14,822

- Location

- UK

It will be interesting to see how it all goes with new NSSS 7th edition.

Indeed!

I heard about the 3rd party WQMS coming in, and it wasn't unexpected that post Grenfell every fabricator is now expected to intumes. every stick of steel that leaves the place.(Not that steelwork was a factor in the fire whatsoever of course...?)

Very knee-jerk. Blather everything in intumescent irrelevent of where its going.

And another little push for us that are CE Ex3 to be BCSA members I see.

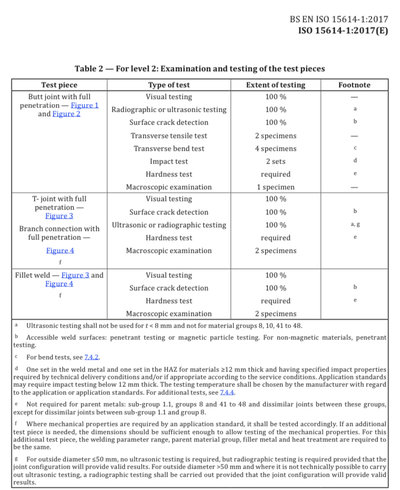

NDT on 304 6mm fillets. I understand DPI is the only form of NDT that can be done? I'm told UT is possible but hard on SS butts, but no chance on SS fillets.

NDT on 304 6mm fillets. I understand DPI is the only form of NDT that can be done? I'm told UT is possible but hard on SS butts, but no chance on SS fillets.