You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best way to apply m2.5 taps in 1.5 mild?

- Thread starter julianf

- Start date

julianf

Member

- Messages

- 8,899

- Location

- devon, uk

No good I'm afraid. I don't get control over the fastener.Use Taptite screws instead (if they exist that small)

Chris Snow

Member

- Messages

- 187

- Location

- Nottingham

Once had a load of 5mm mild steel laser cut for M3. Had to drill them out as they were not accurate enough and also hardened.

julianf

Member

- Messages

- 8,899

- Location

- devon, uk

Ok, so ive approved the laser cutting at 2.3mm dia for the pilots

If anyone wanted to give advice as to changes to the laser cutting, the time for that had passed.

julianf

Member

- Messages

- 8,899

- Location

- devon, uk

Ive picked up the job today, and had a go with the OSG m2.5 tap, with disappointing results -

Using a battery powered drill, the process is fine, however, one thread just seemed to loose torque half way, and, sure enough, an m2.5 machine screw just pushes through.

But...

The other threads are not great either. They feel "loose".

Either the holes were cut on the large side, or my technique is way out, but, in truth, it all seemed pretty simple - load up the tap on low speed, drill in (not a lot of resistance) and drill out again.

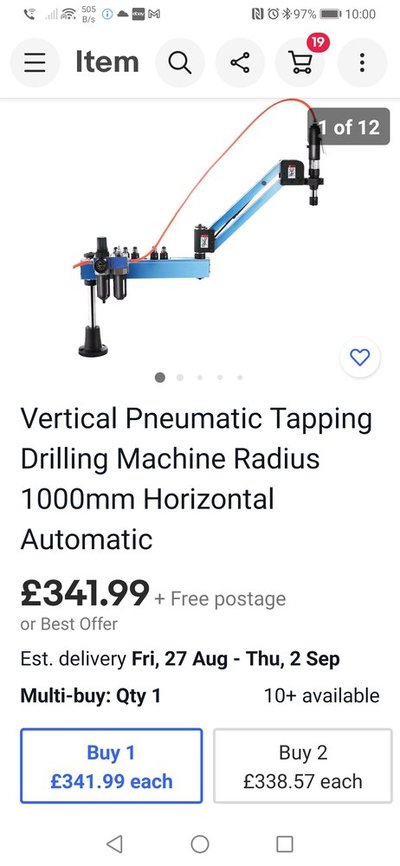

Ive just hit ebay again for one of these -

(ie same again, pretty much, but in M3)

I wanted M2.5, but, as the job is a write off currently, if i can get a good thread to M3, then that will salvage something.

Using a battery powered drill, the process is fine, however, one thread just seemed to loose torque half way, and, sure enough, an m2.5 machine screw just pushes through.

But...

The other threads are not great either. They feel "loose".

Either the holes were cut on the large side, or my technique is way out, but, in truth, it all seemed pretty simple - load up the tap on low speed, drill in (not a lot of resistance) and drill out again.

Ive just hit ebay again for one of these -

M3 Roll Tap Fluteless Coated FETTE LMT | eBay

Find many great new & used options and get the best deals for M3 Roll Tap Fluteless Coated FETTE LMT at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

(ie same again, pretty much, but in M3)

I wanted M2.5, but, as the job is a write off currently, if i can get a good thread to M3, then that will salvage something.

Pete.

Member

- Messages

- 15,074

- Location

- Kent, UK

Roll taps a.k.a thread forming taps are critical on hole size but you get a nice strong thread with them. If your taps are tearing out the threads then I suggest using a better lube.

Why not get the laser company to bash out a test plate in your desired material with a couple of hundred holes say 5 lots of 40 in steps of 0.1mm? That way you can fine-tune your tapping setup for the mass production.

Why not get the laser company to bash out a test plate in your desired material with a couple of hundred holes say 5 lots of 40 in steps of 0.1mm? That way you can fine-tune your tapping setup for the mass production.

julianf

Member

- Messages

- 8,899

- Location

- devon, uk

Roll taps a.k.a thread forming taps are critical on hole size but you get a nice strong thread with them. If your taps are tearing out the threads then I suggest using a better lube.

Why not get the laser company to bash out a test plate in your desired material with a couple of hundred holes say 5 lots of 40 in steps of 0.1mm? That way you can fine-tune your tapping setup for the mass production.

That would be the smart move.

Close inspection shows some marking on the holes from leads, so that may be causing issue also.

Another idea is that I get them to fire the laser at the job to get the pilot positioned correctly and then drill them here. That way I have in-house control over the dia before tapping.

Sure it adds another process but we are talking low thousands of holes on the expected life span of the job, so that may be the easiest solution?

Thank you once again.

Ali

Member

- Messages

- 1,956

- Location

- Cheshire

I don’t think the run out would be a problem, the reversing heads usually have collets with rubber between the jaws that allow a bit of flex.Ok, so ive approved the laser cutting at 2.3mm dia for the pilots, and just ordered one of these -

M2.5 x 0.45 FLUTELESS THREAD FORMING ROLL TAP OSG RH4-P | eBay

Find many great new & used options and get the best deals for M2.5 x 0.45 FLUTELESS THREAD FORMING ROLL TAP OSG RH4-P at the best online prices at eBay! Free delivery for many products.www.ebay.co.uk

which i think is some Japanese company's product.

Ill have a go on the first 5 units (170 holes) with what i have here (drill press, battery drill, etc) and see how i go.

If the job is a go-er, then ill order one of those things for the drill press.

One concern - my drill press has a little run-out. Ive never measured it, but i dont clamp parts when drilling, as there is a little wobble. Obviously more apparent with long drills.

I assume, if people are talking about doing these with hand drills, that getting one of those reversing chucks wont be a problem with some minor run out? Again, its not like ill be clamping the part anyway, as ill be working at speed.

Thanks to all.

julianf

Member

- Messages

- 8,899

- Location

- devon, uk

If I go for the lasered pilot and then opening up the hole to size myself, is this the sort of kit I should be looking at -

www.myford.co.uk

www.myford.co.uk

I don't really do precision stuff by hand so all this is (kind of) new to me!

PRESTO M50 1.0MM - 5.9MM DIN338 HSS DRILL SET 09500M50 - Myford Tools

50 Pcs Jobber Drill Set – 1.0mm – 5.9mm in 0.1mm increments. General-purpose drill, to drill steels with tensile strength up to 1.000 N/mm2, cast steel, grey cast iron, malleable cast iron, nickel brass and graphite. Number of Drills – 50 Material – HSS Finish – P1 Steam Tempered

www.myford.co.uk

www.myford.co.uk

I don't really do precision stuff by hand so all this is (kind of) new to me!

julianf

Member

- Messages

- 8,899

- Location

- devon, uk

Roll taps need precise holes, without any hardening or crap….

As, indeed, I was told earlier! It appears my hopes that the situation would be better have been proved wishful.

So, yes, am now looking for the fix / solution.

I only got a run of 5 made up for exactly the reason that I wasn't certain it would all work out. If I can rework these to M3 it won't be a total waste, and then try and get a workable solution for m2.5 in the future.

Hood

Member

- Messages

- 17,984

- Location

- Carnoustie, Scotland

Personally I would be using a spiral point tap, hole size not so critical and your only issue would be to hold the drill steady when you switch to reverse so that you don't move the drill offline and snap the tap.

I would likely be in high speed on the cordless drill but I suppose that depends on the speeds of your drill.

I would also be looking at a decent quality tap, I only use YG Prime powder metal taps nowadays as I have found them to be as good as the big names and they last me a long time.

I would likely be in high speed on the cordless drill but I suppose that depends on the speeds of your drill.

I would also be looking at a decent quality tap, I only use YG Prime powder metal taps nowadays as I have found them to be as good as the big names and they last me a long time.

Kram

Member

- Messages

- 8,381

- Location

- Sussex

The scrap parts, a blob of braze and try again?

First thing is measure the holes, a set of small drill shanks/pin gauges and a micrometer and see how far out the laser is, or as Pete says, get a test plate made, but thats assuming the settjngs are consitent. They might change things for a production run.

Laser might have left a hard or lumpy edge that the roll tap doesnt like.

I know combined drill/spiral taps exist, not sure if any available are decent quality, but I havent looked.

If laser cutting the holes reduces the effort a lot, then a spiral point tap will be most forgiving, but you will need the smaller 2.05mm holes.

My choice would be get the holes marked. Drill them with a carbide stub drill in drill press just before tapping with cordless.

I use 2.1mm carbide drills for most small holes including with cordless. The reduced flex keeps it right on the centre punch instead of wondering about like a normal hss will.

First thing is measure the holes, a set of small drill shanks/pin gauges and a micrometer and see how far out the laser is, or as Pete says, get a test plate made, but thats assuming the settjngs are consitent. They might change things for a production run.

Laser might have left a hard or lumpy edge that the roll tap doesnt like.

I know combined drill/spiral taps exist, not sure if any available are decent quality, but I havent looked.

If laser cutting the holes reduces the effort a lot, then a spiral point tap will be most forgiving, but you will need the smaller 2.05mm holes.

My choice would be get the holes marked. Drill them with a carbide stub drill in drill press just before tapping with cordless.

I use 2.1mm carbide drills for most small holes including with cordless. The reduced flex keeps it right on the centre punch instead of wondering about like a normal hss will.

- Messages

- 13,577

- Location

- England

Would have been a nice job for flow drilling, tool heats the material and displaces it as it breaks through, then tapped with a roll tap.

The formed hole is usually perfect for the tap. Brilliant on thin sheet metal.

Not sure if they do them quite that small though.

The formed hole is usually perfect for the tap. Brilliant on thin sheet metal.

Not sure if they do them quite that small though.

julianf

Member

- Messages

- 8,899

- Location

- devon, uk

If laser cutting the holes reduces the effort a lot, then a spiral point tap will be most forgiving, but you will need the smaller 2.05mm holes.

My choice would be get the holes marked. Drill them with a carbide stub drill in drill press just before tapping with cordless.

I use 2.1mm carbide drills for most small holes including with cordless. The reduced flex keeps it right on the centre punch instead of wondering about like a normal hss will.

Im quite happy to go with that if it does the job.

I did these with the hand drill, and, whilst they didnt work, it wasnt as random as i thought it would be at all. I do wonder if ill ware out the forwards / reverse slider though!

I dont mind getting the reversing chuck that someone, possibly you, mentioned before, once these teething issues are dealt with.

Ive got the m3 tap ordered now anyway. The job can use m2.5 or m3 - people just like m2.5 as it gives them a little play for alignment issues, but, if it were me, id choose m3 - but its not me buying them, so i have to do what they want, not what i would want!

I got a handful (5) made up. Im hoping they will go to m3, but, even if they dont, ill still spray them up and use them for product photos!