- Messages

- 17,674

Which makes it sound like number 1 is gas test then! Try it again and see if the wire sparks when you touch it against some steel (earth clamp on of course).

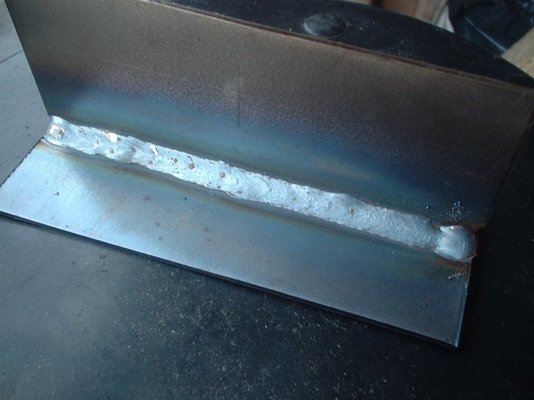

The reason I say those welds are poor is because on most you've only fused to one edge and on others there's so much spattery build up that there will not be much (if any) penetration.

Look at this picture;

The only parts of that vertical plate that have any fusion is the two inches of weld at the top and maybe one or two spots down the right side. The rest has more or less no fusion whatsoever, you can see that clearly by the rolled over edge.

The other patch in that photo is just held on with masses of spatter, there's no proper weld bead to be seen apart from the 1/2" long one going over the corner on the left side.

The other pic with the angled piece in shows just the same, though there is a bit more fusion in places. The vertical right edge of that isn't joined at all at the bottom, you can see the gap between the plate and the parent metal.

The reason I say those welds are poor is because on most you've only fused to one edge and on others there's so much spattery build up that there will not be much (if any) penetration.

Look at this picture;

The only parts of that vertical plate that have any fusion is the two inches of weld at the top and maybe one or two spots down the right side. The rest has more or less no fusion whatsoever, you can see that clearly by the rolled over edge.

The other patch in that photo is just held on with masses of spatter, there's no proper weld bead to be seen apart from the 1/2" long one going over the corner on the left side.

The other pic with the angled piece in shows just the same, though there is a bit more fusion in places. The vertical right edge of that isn't joined at all at the bottom, you can see the gap between the plate and the parent metal.

......As Snoop says ...much better ,however its much easier to weld on a plate than it is to join (butt weld)2 plates together,knowing that you are pushed for time ,follow the advice given to ChrisB on his "first welds" threads ,if you look at his early attempts they look very like your welds on the car ....do some butt welds using the thin metal technique,then try some fillets,post your pics and get some feed back ,we really aren't snobby p1*s takers here ,but your early attempts were not passable for an mot and thats what you need to aim for ....look at the difference in Chris's early welds and later using "thin metal technique" i honestly believe you will achieve better welds quicker ,iI use the same technique on cars as i use Co2 and you can run hotter ,over 1.5-2mm i don't ,but it will get your welding to mot standard quicker...good luck

......As Snoop says ...much better ,however its much easier to weld on a plate than it is to join (butt weld)2 plates together,knowing that you are pushed for time ,follow the advice given to ChrisB on his "first welds" threads ,if you look at his early attempts they look very like your welds on the car ....do some butt welds using the thin metal technique,then try some fillets,post your pics and get some feed back ,we really aren't snobby p1*s takers here ,but your early attempts were not passable for an mot and thats what you need to aim for ....look at the difference in Chris's early welds and later using "thin metal technique" i honestly believe you will achieve better welds quicker ,iI use the same technique on cars as i use Co2 and you can run hotter ,over 1.5-2mm i don't ,but it will get your welding to mot standard quicker...good luck