Morrisman

Forum Supporter

- Messages

- 9,056

- Location

- Staffordshire, England

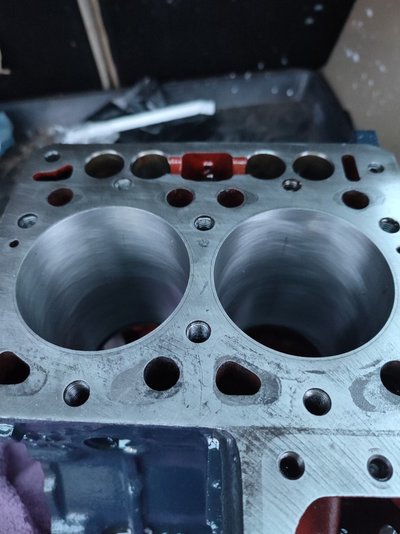

I remember when I worked on a Russian built cold war era seismic vessel years ago. I was 'supervising' 2 Russian mechanics looking after 2000psi 1800cfm LMS air compressors. My company had nowhere else to put me, the industry was on a down turn, so I was essentially a spare body. I even slept in the ships hospital as there was no spare cabin for me.There's a knackered 404d-22 in a 20yo JCB Teletruk where I'm working.

It was working but to my ear rather clattery & rough when I started there back in the summer, slow to rev up & I thought it had a bit of blue smoke.

Hydraulics were slow, it picked up revs slowly & basically ran like a bag of carp. It was also "breathing" quite a bit, pushing oil mist out the oil filler cap.

Owner insisted it was fine, & asked me to service it (Saying he'd paid 2k not that long hence to have the engine "overhauled" - well I looked online for the price of the overhaul kit parts & they were 1.8k alone - so that told me all I needed to know).

I reckoned it was clapped & low compression - but he wouldn't have it (he's ex REME as well).

I changes oil, filters, cleaned out the hydraulic system & replaced the oil & filter, adjusted the valve clearances. It ran better, but not that much better.

In a matter of maybe 2-months it got progressively worse, more smoky & clattery, harder to start.... but he insisted the smoke & rough running was just due to an injector, & the poor starting down to glow plugs.

(I tested the GP's & all 4 were OK, & it was breathjng so hard it was blasting smoke & oil from the filler, remove the dipstick on idle amd it blew smoke & oil drops out, & using oil excessively now).

l told him again IMO him it was forked - but he kept using it.

It's now been sitting dead as a boat anchor I the yard for the last 3-months..

The compressor engines ran a bit rough, and one would not pull full operating rpm properly. I asked about maintenance procedures and records, and was assured these Russian guys knew what they were doing, and I was basically told to keep my nose out.

My company eventually had a team of guys come out to the ship in Singapore, and they did a full rebuild on the one 12v/71 that wouldn't rev properly. After a weeks work and a $100,000 bill it was run up, warmed up for a while, then put under load..... and still wouldn't pull full rpm.

I put my foot down and got the engine overhaul guys to shut it down and pull the air filters off. When it was fired up it sound different, and surprise surprise, it pulled full rpm with glee!

I had been secretly digging through the spares store, of which there was very little, and found two boxed up air filters, both were used and dirty. Their idea of changing air filters was to blow them out with an airline and put the used ones back in the stores, and get the other two out. How long that had been going on is anybody's guess.

The Russian guys, nice enough chaps, both from Azerbaijan, would throw nothing away, all used spares were kept, old gaskets, broken parts, stripped bolts, everything was stashed away somewhere. I guess years of 'austerity' in the collapsed USSR had done that to them.