For now you can figure that out really easily by putting a dial gauge on a magnetic stand on the wheel head so the plunger is vertical and just zero it at the top of the chuck and crank the head down a whole crank of the wheel, and divide it by the number of graduations on one turn. Do more turns and divide by the number of turns too if you want to be more accurate.I redressed the wheel and off we went - this time made sure to use lighter cuts (1 or 2 notches on the wheel - I still need to figure out what each notch increment is - a DRO will definitely help).

- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Jones & Shipman 540P Surface grinder post

- Thread starter Pawcu

- Start date

@jmp49 thanks for your feedback and pictures - really appreciate it

Yeah I would love to get my hands on a balancer - the previous owner has a balancer but no arbor, but I might be able to get an arbor machined so will see. And you're right you can definitely see a nicer finish on the right one congrats - I heard that on smaller wheels balancing is not required as much but it clearly shows that it still affects.

- I heard that on smaller wheels balancing is not required as much but it clearly shows that it still affects.

And yes really thinking about getting a DRO - wasn't planning to but as you mentioned, it was a bit of a hassle to get the wheel to touch off again after dressing it, a DRO will definitely help in that area. Mind I ask how you mounted the scales for the head (is that the z axis or is it the Y since is perpendicular to the spindle?)

Thanks for the tip of the Dial gauge - I will definitely need to do that till I get the DRO sorted xD

Yeah I would love to get my hands on a balancer - the previous owner has a balancer but no arbor, but I might be able to get an arbor machined so will see. And you're right you can definitely see a nicer finish on the right one congrats

- I heard that on smaller wheels balancing is not required as much but it clearly shows that it still affects.

- I heard that on smaller wheels balancing is not required as much but it clearly shows that it still affects.And yes really thinking about getting a DRO - wasn't planning to but as you mentioned, it was a bit of a hassle to get the wheel to touch off again after dressing it, a DRO will definitely help in that area. Mind I ask how you mounted the scales for the head (is that the z axis or is it the Y since is perpendicular to the spindle?)

Thanks for the tip of the Dial gauge - I will definitely need to do that till I get the DRO sorted xD

I didnt take pics because I'd got burned out on posting stuff that period and decided to just do stuff for just myself, but I'll do so in the next day or two, its better explained in pictures, but its not perfect, I have to take one scale off to remove the table. I've also got a lot of backlash in the wheel head screw, so I can compensate for that as the dro shows true movement, not what the dials and 70 years of wear say it is, thats the other great thing about a dro everybody forgets. I put scales on every axis because I thought why not, a lot of people told me that was useless and I just needed the wheel head, but I have found it useful since doing it.

My arbor was a random piece of steel in the scrap bin at the start. I taper turned it where the wheel fitted, and then ground it in on the surface grinder between centres, so definitely worth grabbing the balancer without imho.

I measured the taper on the hub as best I could between 7 & 8 degrees, then set the topslide on my lathe to the same, and taper cut on a piece of scrap, then checked it with blu, nudged the topslide angle and repeated until it printed perfectly. I think I had to do this 8 times

Once I did this, I put the eventual workpiece in the lathe and turned the taper on it, then the other elements, then touched them off in the grinder between centres and finished there. I keep resisting the temptation to buy a cylindrical grinder due to limited space, so the setting up a cross table on the machine and locking the long axis trick is handy.

Once done, you can push the arbor into the hub and it stays there with stiction enough to balance with so no retaining nut/thread needed for me.

On my wheel hub you can see two allen grub screws, on this design I can back off these screws and slide around the piece of metal around them to balance the wheel/hub as one unit. On some you have to shave material off the wheel instead carefully to achieve this. I think I said already if you get chance to get a bunch of hubs, do so, this is the reason why, you dont need to rebalance and can just do a light touch off if you keep the hub/wheel as a unit together, so it makes changing wheels/grade/diameter much quicker.

My arbor was a random piece of steel in the scrap bin at the start. I taper turned it where the wheel fitted, and then ground it in on the surface grinder between centres, so definitely worth grabbing the balancer without imho.

I measured the taper on the hub as best I could between 7 & 8 degrees, then set the topslide on my lathe to the same, and taper cut on a piece of scrap, then checked it with blu, nudged the topslide angle and repeated until it printed perfectly. I think I had to do this 8 times

Once I did this, I put the eventual workpiece in the lathe and turned the taper on it, then the other elements, then touched them off in the grinder between centres and finished there. I keep resisting the temptation to buy a cylindrical grinder due to limited space, so the setting up a cross table on the machine and locking the long axis trick is handy.

Once done, you can push the arbor into the hub and it stays there with stiction enough to balance with so no retaining nut/thread needed for me.

On my wheel hub you can see two allen grub screws, on this design I can back off these screws and slide around the piece of metal around them to balance the wheel/hub as one unit. On some you have to shave material off the wheel instead carefully to achieve this. I think I said already if you get chance to get a bunch of hubs, do so, this is the reason why, you dont need to rebalance and can just do a light touch off if you keep the hub/wheel as a unit together, so it makes changing wheels/grade/diameter much quicker.

Thanks pictures will definitely be appreciatedI didnt take pics because I'd got burned out on posting stuff that period and decided to just do stuff for just myself, but I'll do so in the next day or two, its better explained in pictures, but its not perfect, I have to take one scale off to remove the table. I've also got a lot of backlash in the wheel head screw, so I can compensate for that as the dro shows true movement, not what the dials and 70 years of wear say it is, thats the other great thing about a dro everybody forgets. I put scales on every axis because I thought why not, a lot of people told me that was useless and I just needed the wheel head, but I have found it useful since doing it.

My arbor was a random piece of steel in the scrap bin at the start. I taper turned it where the wheel fitted, and then ground it in on the surface grinder between centres, so definitely worth grabbing the balancer without imho.

I measured the taper on the hub as best I could between 7 & 8 degrees, then set the topslide on my lathe to the same, and taper cut on a piece of scrap, then checked it with blu, nudged the topslide angle and repeated until it printed perfectly. I think I had to do this 8 times

Once I did this, I put the eventual workpiece in the lathe and turned the taper on it, then the other elements, then touched them off in the grinder between centres and finished there. I keep resisting the temptation to buy a cylindrical grinder due to limited space, so the setting up a cross table on the machine and locking the long axis trick is handy.

Once done, you can push the arbor into the hub and it stays there with stiction enough to balance with so no retaining nut/thread needed for me.

On my wheel hub you can see two allen grub screws, on this design I can back off these screws and slide around the piece of metal around them to balance the wheel/hub as one unit. On some you have to shave material off the wheel instead carefully to achieve this. I think I said already if you get chance to get a bunch of hubs, do so, this is the reason why, you dont need to rebalance and can just do a light touch off if you keep the hub/wheel as a unit together, so it makes changing wheels/grade/diameter much quicker.

View attachment 493457

I found some 0.1um scales on ebay which I'm thinking of getting for the head and 1um for the saddle travel.

I'm not sure if I have the skill yet to machine the arbor - will get a friend of mine to do it for me :P

Regarding the hub I have an extra one (possibly 2) and the one I have on the machine for sure has the weights... which in hind sight I should have probably removed xD

I still need to go through the whole pile of grinding wheels I have to sort out what they're for and their grit etc...

You mentioned you lock the long axis on the machine, was this something you added yourself or it came with the machine cause I dont seem to have a lock on the long axis, only on the saddle

I added it by drilling and tapping a bolt in that I can nip up to lock the slideway, originally my machine was a all hydraulic machine running production in a factory, so they didnt need the facility to lock things etc. Picture from when it was actually clean. You can see the finger gauge magneted to the workhead while tramming in the end fence of the magnetic chuck so I can use it as a known true reference to position things on.

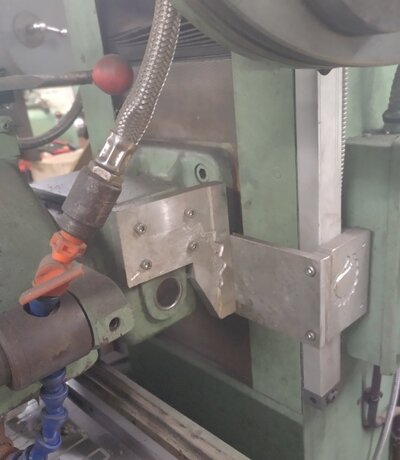

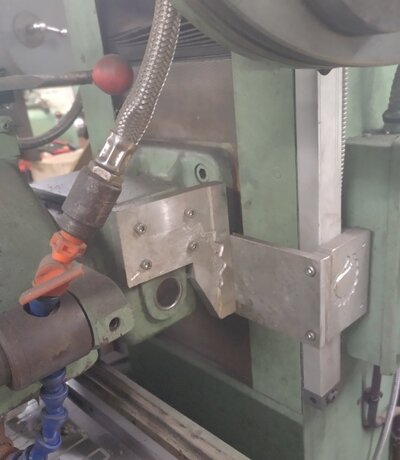

DRO scales today, I need to clean it badly. First the head scale, Ignore the funny shapes on the alloy parts, they were test pieces from my cnc milling machine conversion and spare in the scrapbin. They assemble with the m6 allens, and hidden pins locate them so you can remove the joiner to remove it without disturbing the scale body itself which is tapped into the casting of the machine.

Next the saddle cross axis, its tucked away beneath the rightmost end above the hydraulic controls for the long axis, out the way of grit and flying objects

Finally the long axis, its hard to see, but the scale head is screwed to the lower half of the casting, and the machine table is tapped for the scale body, so the wire stays stationary and it can have the gap facing downwards to help with not getting grinding dust in it, which inevitably will happen over time anyway. But I'll just replace it with another cheap chinese scale anyway then.

It eliminates this nonsense written in sharpie on the machine casting itself. I may have burnt workpieces once or twice getting the sums wrong and taking massive cuts by accident before doing this.

The sad bit is it also makes access to under the saddle much more awkward, and while most tasks can be done with the slide covers moved, I have to change a hydraulic hose that powers the long axis hydraulic cylinder as it split and thats impossible with the table in place. I've been putting off doing it for a few years now and just using it manually.

You dont remove the weights to be clear, you put them at 12 o'clock and 6 o'clock to offset each other, then alter the positions progressively away from the heavy spot identified on the balancer by sliding them round, the weights dont come out the hub at all without disassembly of the hub itself because this would be really dangerous if they came loose in service and flew off, theyre kept in by their shapes and the shape of the groove they slide in, and the grub screw forces the weights taper shape into the hub female taper rather than screwing into anything.

DRO scales today, I need to clean it badly. First the head scale, Ignore the funny shapes on the alloy parts, they were test pieces from my cnc milling machine conversion and spare in the scrapbin. They assemble with the m6 allens, and hidden pins locate them so you can remove the joiner to remove it without disturbing the scale body itself which is tapped into the casting of the machine.

Next the saddle cross axis, its tucked away beneath the rightmost end above the hydraulic controls for the long axis, out the way of grit and flying objects

Finally the long axis, its hard to see, but the scale head is screwed to the lower half of the casting, and the machine table is tapped for the scale body, so the wire stays stationary and it can have the gap facing downwards to help with not getting grinding dust in it, which inevitably will happen over time anyway. But I'll just replace it with another cheap chinese scale anyway then.

It eliminates this nonsense written in sharpie on the machine casting itself. I may have burnt workpieces once or twice getting the sums wrong and taking massive cuts by accident before doing this.

The sad bit is it also makes access to under the saddle much more awkward, and while most tasks can be done with the slide covers moved, I have to change a hydraulic hose that powers the long axis hydraulic cylinder as it split and thats impossible with the table in place. I've been putting off doing it for a few years now and just using it manually.

You dont remove the weights to be clear, you put them at 12 o'clock and 6 o'clock to offset each other, then alter the positions progressively away from the heavy spot identified on the balancer by sliding them round, the weights dont come out the hub at all without disassembly of the hub itself because this would be really dangerous if they came loose in service and flew off, theyre kept in by their shapes and the shape of the groove they slide in, and the grub screw forces the weights taper shape into the hub female taper rather than screwing into anything.

Thanks for the pictures they do help

I was thinking of putting the head axis inside because of the grit and I cannot do it on the right side (opposite the dust to be clear) because i have the limit switch for the power rise and and fall - I mean I guess i can still do it if I need to just needs extra bracketry and faffing about. Will see - need to order them first xD

And thanks for the tip about the weights - I'll try and get around to putting them as you mentioned

I was thinking of putting the head axis inside because of the grit and I cannot do it on the right side (opposite the dust to be clear) because i have the limit switch for the power rise and and fall - I mean I guess i can still do it if I need to just needs extra bracketry and faffing about. Will see - need to order them first xD

And thanks for the tip about the weights - I'll try and get around to putting them as you mentioned

I was going to put the head axis scale inside, then I removed all the rear covers and there was no real space without drilling big holes in internal braces inside it, and I didnt want to alter the structure at all like that because the accuracy and stability of the machine is all about that column strength so I'd rather ruin the scale over a long timespan than the machine. I dont have power rise and fall, just a fine and coarse mode that changes gearing inside the crank handle!

I don't know J&S grinders to know if the column is the same situation, be interesting to see if its possible on them and sure there are other people have done it on these machines to get inspiration from.

As is I've got it round the corner out the worst debris area even though I couldnt work out a way to robustly add a extra shield over it, and I always true the wheel with coolant on and wet grind to cut down on dust, a lot of this dust is because I havent been in the machine workshop as much lately rather than grit and its not been covered up.

I have seen a lot of rubber bellows on aliexpress etc appear lately, and wondered if you could put the scale inside one somehow, but for me its been fine for about 6 years like this, and it has wipers built in & scales are cheap to replace.

Look forward to your updates.

I don't know J&S grinders to know if the column is the same situation, be interesting to see if its possible on them and sure there are other people have done it on these machines to get inspiration from.

As is I've got it round the corner out the worst debris area even though I couldnt work out a way to robustly add a extra shield over it, and I always true the wheel with coolant on and wet grind to cut down on dust, a lot of this dust is because I havent been in the machine workshop as much lately rather than grit and its not been covered up.

I have seen a lot of rubber bellows on aliexpress etc appear lately, and wondered if you could put the scale inside one somehow, but for me its been fine for about 6 years like this, and it has wipers built in & scales are cheap to replace.

Look forward to your updates.

I checked yesterday and there is a bit of room at the top... but will need to see how that will pan out once I have the scale itself. A friend of mine installed his on the bottom in the front near the motor with a bracket going to the back plate (so the scale is not mounted to the plate with the rubber mounts as that will obviously throw the reading off). He still has to test it out first to see if it will work accurately enough so I am waiting for him to try it out first before I go to that approach xD

But yes if all else fails I will most probably mount them on the outside like yours and just use 'larger' brackets to go around the limit switch and what not.

But yes if all else fails I will most probably mount them on the outside like yours and just use 'larger' brackets to go around the limit switch and what not.