duncans

Member

- Messages

- 731

- Location

- leicester

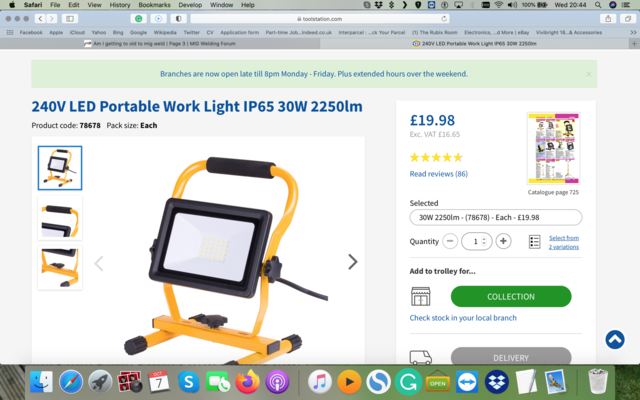

hi DARPH I've got type 2 as well squirt that fluid in my eyes that sting like billio and pictures took they can find all types of things that can be up with you when they look at the pictures I've been fine these past 3 or 4 times I've had to go and agree the 30 watt led lights make a huge difference

Aha, amazing what the search function'll store for future reference, certainly for longer than we will.......

Aha, amazing what the search function'll store for future reference, certainly for longer than we will.......