You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A few random stainless jobs

- Thread starter Paul.

- Start date

- Messages

- 23,942

- Location

- Birmingham

Do they give you a "fag packet" drawing with rough dimensions and leave the design to you?

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

Just a phone call along the lines of "need a stand for a short person asap, leave it with you", that's the spec, never had a drawing from this customer for anything I've ever made for them,Do they give you a "fag packet" drawing with rough dimensions and leave the design to you?

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

Just done with a flap wheel, I keep the old ones for corners cos it puts a groove in them if you have a lot to do,Hi Paul,

How do you radius the edge of the plate so nicely. That's a really nice touch.

Last edited:

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

Another job finished today,

Customer is moving into a new office and has fitted a fully glazed door to get some light in, to try and deter out of hours visitors I built this to cover it up,

40 x 40 stainless box section with an aluminium front panel bonded and riveted on, frame is fixed to the brickwork with a combination of large coach screws and plastic plugs, resin anchors , and through bolts into the concrete floor, a couple of keyed alike disclocks will keep it closed,

Its in an enclosed courtyard, which helps with the security, and also makes it tricky to get a decent picture.

These are the hinges, the hexagon flats have since been turned off and the nuts tig welded on

Customer is moving into a new office and has fitted a fully glazed door to get some light in, to try and deter out of hours visitors I built this to cover it up,

40 x 40 stainless box section with an aluminium front panel bonded and riveted on, frame is fixed to the brickwork with a combination of large coach screws and plastic plugs, resin anchors , and through bolts into the concrete floor, a couple of keyed alike disclocks will keep it closed,

Its in an enclosed courtyard, which helps with the security, and also makes it tricky to get a decent picture.

These are the hinges, the hexagon flats have since been turned off and the nuts tig welded on

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

......with an aluminium front panel bonded and riveted on

Just for future reference, what did you use for the bonding?

Screwdriver

Member

- Messages

- 10,969

I want to say it's like torture seeing all this amazing work but actually it is inspiring. There is an elegant simplicity to your design which just shouts quality.

Great stuff.

Great stuff.

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

3m panelbond, they use it for sticking cars together, it had a line of 3m round it and a parallel line of sticks like alongside it and round the rivets to keep the water out,Just for future reference, what did you use for the bonding?

just in case the rivets let water through its got some drain holes in the bottom, I've seen square box sections bulge and split when filled with water that turns to ice.

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

This one was a teaser, all those angled cuts and the notching to fit round the legs, very fiddly, its a counter to be used in an exhibition and will be clad in board with some fancy graphics on it, so most of the metalwork will not be seen. no mug for scale but its 2 mtrs long and the legs are 4" dia tube

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

^^^ Seems a shame to cover that up.

- Messages

- 23,942

- Location

- Birmingham

What happens to it after the exhibition?, most stands are skipped when the doors close

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

This is for one of my regular customers, it will be used as a product display stand in their reception area after the show.What happens to it after the exhibition?, most stands are skipped when the doors close

gordon stephenson

Member

- Messages

- 7,430

- Location

- Skelton in Cleveland U.K.

No more words,, Just superb, (as usual) Thanks for sharing Paul.

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

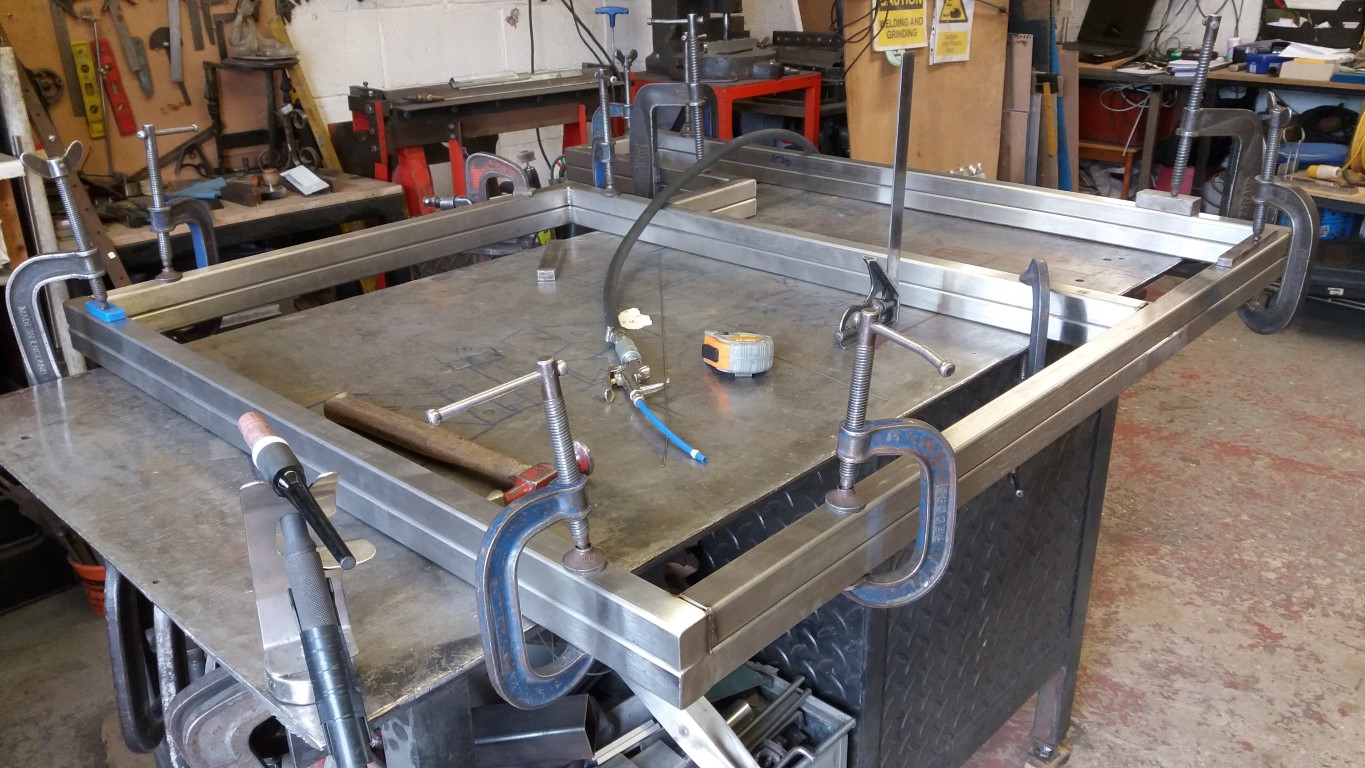

A bit of machine guarding here, its 30 x 30 x 3 stainless box, those that have ever welded it will know how much it distorts when welding so a bit of thought with welding sequence and a lot of air quenching to keep the heat down on this one,

Make up one end and then use it as a jig to build the second one

Then assemble it, the bits of red oxide UB have levelling bolts in them for laying up jobs like these, as you can see the floor has a bit of a slope on it, plenty of clamps make the job easy(ish).

And completed, the sun made a decent photo a bit tricky but you'll get the idea, its 2.5 mtrs long and about 1.2m square so bigger than the photo makes it look.

Make up one end and then use it as a jig to build the second one

Then assemble it, the bits of red oxide UB have levelling bolts in them for laying up jobs like these, as you can see the floor has a bit of a slope on it, plenty of clamps make the job easy(ish).

And completed, the sun made a decent photo a bit tricky but you'll get the idea, its 2.5 mtrs long and about 1.2m square so bigger than the photo makes it look.

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

Ok, its not stainless but I'll stick this here anyway.

Got these finished today,

Enclosures for those MUX multiplexing thigimajigs that they use in networks etc, normally they are fitted horizontally in the racks but this is to mount them vertically, the idea is that the internal fans in the MUX suck the air in at the bottom and blow it out the top, nice little project thad I had to design and make six off in total, its all mild steel the outer bodies are 1.5mm and the inner is 1.2mm,

And what a difference a bit of powder coating makes

And one of the internal welds, all migged, not too much welding though to keep the distortion to a minimum

Got these finished today,

Enclosures for those MUX multiplexing thigimajigs that they use in networks etc, normally they are fitted horizontally in the racks but this is to mount them vertically, the idea is that the internal fans in the MUX suck the air in at the bottom and blow it out the top, nice little project thad I had to design and make six off in total, its all mild steel the outer bodies are 1.5mm and the inner is 1.2mm,

And what a difference a bit of powder coating makes

And one of the internal welds, all migged, not too much welding though to keep the distortion to a minimum

Bill Edwards

Member

- Messages

- 4,935

- Location

- Scarborough, North Yorkshire

Looks decent Paul

WorkshopChris

Member

- Messages

- 4,987

- Location

- South East Essex

Looks good, Do you ever have problems with contamination when working mild steel in a mainly stainless environment. Or is it just a case of keeping disks separate and watching for sparks and grinding dust.

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

Looks good, Do you ever have problems with contamination when working mild steel in a mainly stainless environment. Or is it just a case of keeping disks separate and watching for sparks and grinding dust.

No real problems, I don't have much space to store much stock so there is usually very little around to get contaminated, separate disks and keeping the storage rack covered is enough, the main cause for contamination in a lot of shops is when people grind mild steel and the fallout lands on stainless stock, a bit of damp and you have a problem, but its not as big an issue for general work as the internet would have everyone believe, benchtops, cutting tools, vices, files etc. are all steel, and come into contact with stainless getting worked, if the jobs cleaned up properly before it goes out then shouldn't really be a problem, I certainly have never had any complaints about anything I've ever made

I once worked on a specialised medical equipment project and the customer insisted on a dedicated isolated work area with stainless benches, but everything I made went out for electro polishing or bead blasting, so it was all a bit ott really