You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

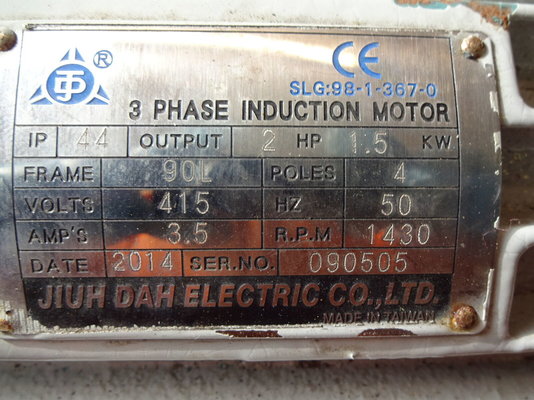

3ph motor running with VFD

- Thread starter Bsmith

- Start date

Brad93

Member

- Messages

- 19,436

- Location

- Essex, United Kingdom

Not without pulling the windings to make it run on 220v

northwest

Searching for the Holy Grail.........

- Messages

- 6,673

- Location

- Manchester UK

Well, yes and no. It can be ran with a 415volt VFD but I suspect what you are asking is "Can this motor run off a 240volt VFD"? and the answer is no.

However if you get someione to pull the points outof the wiring then you could run it 220 volts*

*someone far better able than I will be along shortly to explain.

However if you get someione to pull the points outof the wiring then you could run it 220 volts*

*someone far better able than I will be along shortly to explain.

Well no, no yes. You can run it on 240vsd, as @not done it yet says it will be on reduced torque, or reduced speed. I run a 4.5 kW mill on 240v, just haven't got around to pulling the windings yet.Well, yes and no. It can be ran with a 415volt VFD but I suspect what you are asking is "Can this motor run off a 240volt VFD"? and the answer is no.

However if you get someione to pull the points outof the wiring then you could run it 220 volts*

*someone far better able than I will be along shortly to explain.

Ahh ok thanks fellas. My boxford lathe has a 1+1/2 hp single phase motor, it struggles a bit when turning bigger dia stuff. Thought if I got a 2hp, 3 phase motor and a vfd it would be powerful enough for all. I also believe 3 phase is smoother running and I like the speed control on vfd.

uk.banggood.com

uk.banggood.com

Do you have a link to the vfd you were thinking of?

Stu

Topshak AT1-2200X 2.2KW 220V PWM Control Inverter 1Phase Input 3Phase Out Inverter Variable Frequency Inverter

Only US$104.99, buy best Minleaf AT1-2200X 2.2KW 220V PWM Control Inverter 1Phase Input 3Phase Out Inverter Variable Frequency Inverter sale online store at wholesale price.

My Old Landy

Engineering Mayhem

- Messages

- 3,498

- Location

- North Lincs

In essence yes. Choose a motor with the mounting option to suit your application. If using a cheaper vfd rate it slightly higher than required. I have two lathes and a mill all running off vfd's (there are posts on the forum showing mine and a few vids on my YouTube channel).So, to do what I would like I would need a 2hp, 220v 3phase motor and a vfd? Would I be ok with them?

Pete.

Member

- Messages

- 15,074

- Location

- Kent, UK

Ahh ok thanks fellas. My boxford lathe has a 1+1/2 hp single phase motor, it struggles a bit when turning bigger dia stuff. Thought if I got a 2hp, 3 phase motor and a vfd it would be powerful enough for all. I also believe 3 phase is smoother running and I like the speed control on vfd.

1.5hp is a good match for a Boxford. Are you sure that it's not belt slip? What do you call 'bigger stuff' ?

brightspark

Member

- Messages

- 41,590

- Location

- yarm stockton on tees

a 1 hp quality old english motor will be fine/ if not a foreign or a clark 1,5 hp

Agroshield

Member

- Messages

- 6,395

In essence yes. Choose a motor with the mounting option to suit your application.

The challenge is if the motor shaft diameter is different to the existing one. The drive pulley will not then fit the new motor and you cannot put it in the lathe to alter its bore as it is coming off the old motor that is driving the lathe. The solution is obvious: never own only one lathe.

brightspark

Member

- Messages

- 41,590

- Location

- yarm stockton on tees

or have a mate or brother that has oneThe challenge is if the motor shaft diameter is different to the existing one. The drive pulley will not then fit the new motor and you cannot put it in the lathe to alter its bore as it is coming off the old motor that is driving the lathe. The solution is obvious: never own only one lathe.

6 - 8" dia I also find the lathe heavy to start in cold weather especially when using the gear train. Maybe the motor does not provide the power it is plated to do. It was one of the cheaper £Bay motors. If I remember right I think the original motor was 1hp 415v.1.5hp is a good match for a Boxford. Are you sure that it's not belt slip? What do you call 'bigger stuff' ?

Changed motors once or twice before so have 2 pulleys.The challenge is if the motor shaft diameter is different to the existing one. The drive pulley will not then fit the new motor and you cannot put it in the lathe to alter its bore as it is coming off the old motor that is driving the lathe. The solution is obvious: never own only one lathe.