To be fair, I think Alfa at that time were as good as everyone else at rust proofing. Afterall, how many J-reg Fords, Rovers, etc do you see around anymore? Especially as it probably hasn't had any rust-proofing topups ever, and not in the last 10 years when it was just an old car . . .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

25 year old Alfa 75 back from the brink (hopefully)

- Thread starter Dcal

- Start date

Dieselman 63

Forklift Certified

- Messages

- 5,872

- Location

- Wellington, New Zealand

They were notorious for gaining rust quickly though. Same with Lancias - beautiful shapes but rusted before your eyes.

jpmillermatic

Member

- Messages

- 1,094

bravo, bravo!

very nicely done.

JP

very nicely done.

JP

Again, only as much as just about everything else around - but the scare story the Mirror put around about series one Lancia Beta saloon engines falling out allowed me to buy some excellent cars very cheaply over the years and wear them out.They were notorious for gaining rust quickly though. Same with Lancias - beautiful shapes but rusted before your eyes.

(The engines couldn't fall out, but they did rust around the rear engine mount, and unlike say Austin where your 1100 and Mini rear subframe might need replacing at the first MOT, they bought them back - and so the story started . . .)

Dieselman 63

Forklift Certified

- Messages

- 5,872

- Location

- Wellington, New Zealand

Again, only as much as just about everything else around - but the scare story the Mirror put around about series one Lancia Beta saloon engines falling out allowed me to buy some excellent cars very cheaply over the years and wear them out.

(The engines couldn't fall out, but they did rust around the rear engine mount, and unlike say Austin where your 1100 and Mini rear subframe might need replacing at the first MOT, they bought them back - and so the story started . . .)

My dad hammered his delta, he sold it when the sills were going... and the badge kept getting nicked meaning it rusted there... and the window trims were bubbling and then she went the way of many Italian cars, the electrics went haywire! Still, a Passat is an upgrade right?

Hmm - dunno about a Passat!

I bought my first integrale while I still had my 75 TS, a Beta Spyder and a Beta Coupe. Sold the 75 TS (Hi Rufus ;-) - where's me radio? ) and the Betas. Used the integrale as a sensible car in all weathers, leaving it outside, for 10 yrs ish. Did no welding on it. Bought an integrale evo and stuck a tow bar on it - abused that for 12yrs or so. Just swopping the engine out - I swopped last year to Petronus 20W50 following an expert opinion . . . destroyed a big end the other week. When it goes back in, it'll have a diet of Millers 10W60 as per the last 20yrs . . .

Any how, back to the 75 . . ;-)

I bought my first integrale while I still had my 75 TS, a Beta Spyder and a Beta Coupe. Sold the 75 TS (Hi Rufus ;-) - where's me radio? ) and the Betas. Used the integrale as a sensible car in all weathers, leaving it outside, for 10 yrs ish. Did no welding on it. Bought an integrale evo and stuck a tow bar on it - abused that for 12yrs or so. Just swopping the engine out - I swopped last year to Petronus 20W50 following an expert opinion . . . destroyed a big end the other week. When it goes back in, it'll have a diet of Millers 10W60 as per the last 20yrs . . .

Any how, back to the 75 . . ;-)

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

Bricol,

We seem to have very similar tastes in cars.

I also take your point on reputation.

I've driven Italian cars, mostly fiats, ever since I started driving.

Always liked them and they were dirt cheap because of the reputation Italian cars have over here.

Standout ones were a 124 coupe and a 131 racing. I drove both of them into the ground without any major issues.

Would love to have either of them now

Ive also got a Delta in bits on a spit.

Got all the welding and bodywork done and its waiting for top coat. Went completely nuts on it, back to metal both top and bottom. There wasn't a grommet left on the shell. Lost interest a bit when everything I need costs a fortune.

I'll get back to it when I have the alfa on the road

Bummer on your Delta.

Is your crank OK? As I'm sure you know, they are hardened and you aren't suppose to regrind them. The engine in mine had undersized shells and ran great oil pressure. According to the receipts that came with it, they were replaced a fair while ago and seem to be holding up.

The 75 was supposed to be a stopgap that I could easily get on the road. Hasn't worked out that way

Dieselkid was you dads an Integrale?

I can't remember any of my Fiats having electrical issues, maybe I was just lucky.

We seem to have very similar tastes in cars.

I also take your point on reputation.

I've driven Italian cars, mostly fiats, ever since I started driving.

Always liked them and they were dirt cheap because of the reputation Italian cars have over here.

Standout ones were a 124 coupe and a 131 racing. I drove both of them into the ground without any major issues.

Would love to have either of them now

Ive also got a Delta in bits on a spit.

Got all the welding and bodywork done and its waiting for top coat. Went completely nuts on it, back to metal both top and bottom. There wasn't a grommet left on the shell. Lost interest a bit when everything I need costs a fortune.

I'll get back to it when I have the alfa on the road

Bummer on your Delta.

Is your crank OK? As I'm sure you know, they are hardened and you aren't suppose to regrind them. The engine in mine had undersized shells and ran great oil pressure. According to the receipts that came with it, they were replaced a fair while ago and seem to be holding up.

The 75 was supposed to be a stopgap that I could easily get on the road. Hasn't worked out that way

Dieselkid was you dads an Integrale?

I can't remember any of my Fiats having electrical issues, maybe I was just lucky.

Dieselman 63

Forklift Certified

- Messages

- 5,872

- Location

- Wellington, New Zealand

Bricol,

We seem to have very similar tastes in cars.

I also take your point on reputation.

I've driven Italian cars, mostly fiats, ever since I started driving.

Always liked them and they were dirt cheap because of the reputation Italian cars have over here.

Standout ones were a 124 coupe and a 131 racing. I drove both of them into the ground without any major issues.

Would love to have either of them now

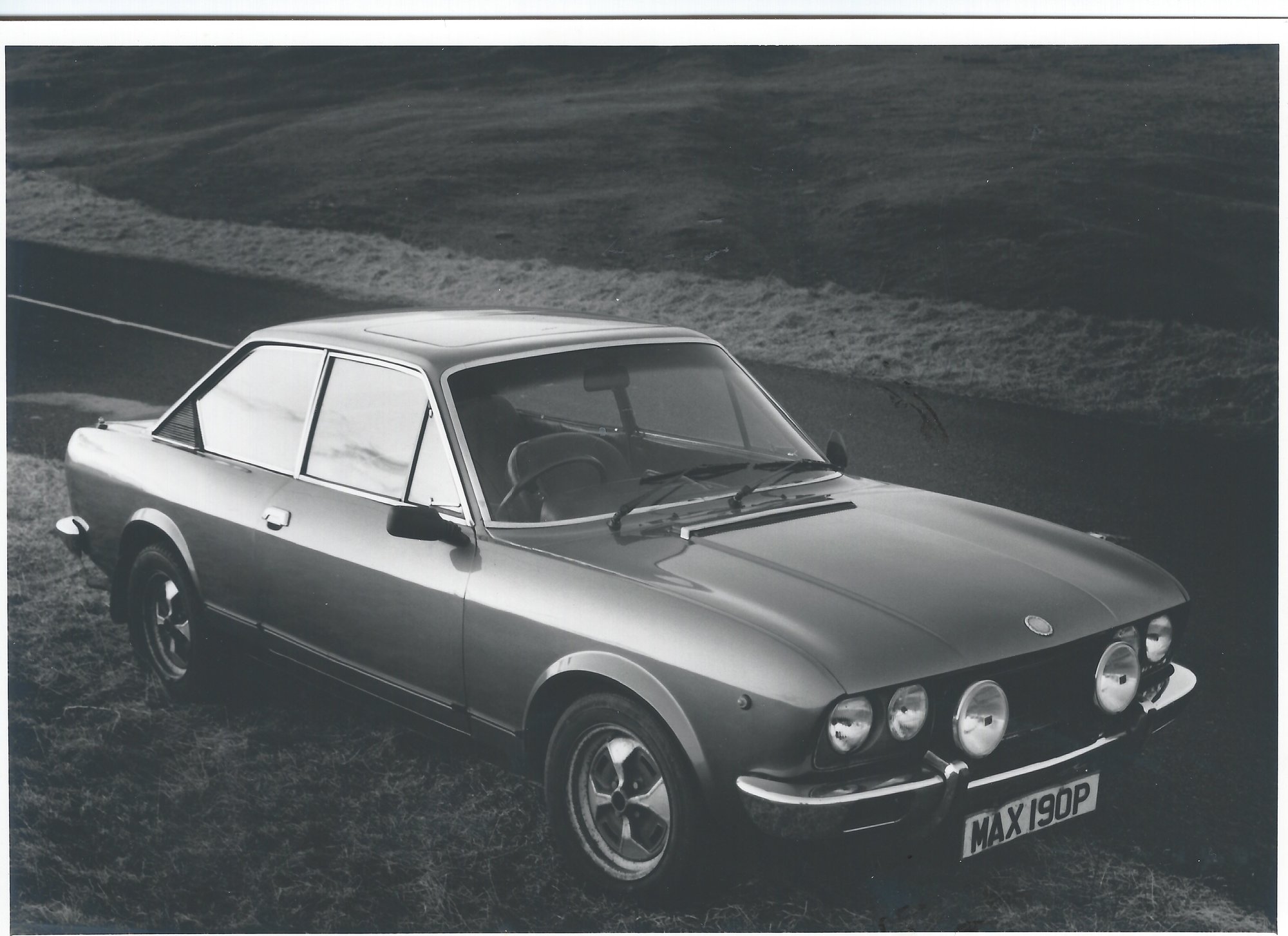

View attachment 140474

Ive also got a Delta in bits on a spit.

Got all the welding and bodywork done and its waiting for top coat. Went completely nuts on it, back to metal both top and bottom. There wasn't a grommet left on the shell. Lost interest a bit when everything I need costs a fortune.

I'll get back to it when I have the alfa on the road

Bummer on your Delta.

Is your crank OK? As I'm sure you know, they are hardened and you aren't suppose to regrind them. The engine in mine had undersized shells and ran great oil pressure. According to the receipts that came with it, they were replaced a fair while ago and seem to be holding up.

View attachment 140475

The 75 was supposed to be a stopgap that I could easily get on the road. Hasn't worked out that way

Dieselkid was you dads an Integrale?

I can't remember any of my Fiats having electrical issues, maybe I was just lucky.

Nope just the standard block lamp one. Still a pocket rocket or so he claims! Used to do Southport to Manchester daily then all the way to Durham at the weekends, maybe 1993/4?

You mean like this:

It was a bit of a breath in moment the first time I rolled it over . . .

Worked on it when I felt like it, didn't when I didn't. Back on the road last August.

Cranks are nitrided and it is indeed recommended not to regrind as you go through it - but Lancia sell undersized shells . . . Pretty confident mine is under-undersize now! Shame as someone in the past prepared it well. I have a spare N/A engine from a Thema (or something) sat in the shed with a hopefully good crank. I was so hacked off/depressed/fed up I bought a complete Fiat coupe engine from Martin at Deltaparts (known him for over 16yrs or so, so trust the engine is good). I've had to swop so much over between the two, I might as well bought a new crank and rebuilt my engine. Re-manufactured turbo coming next week - my 200,000 unit is rather worn!

I bought a 159 3.2 Q4 unseen on ebay as my stop gap. Needed something to tow with and missed the integrale - getting in and out of trialing field with a trailer behind with a car on is a little easier with all wheels driving. Had that 18mths and it needed the prop bearing doing - think I've mentioned that on here before.

Had a couple of electrical issues with italian cars - the 75 oil level sensor went up the creek - so it lit the LED on the check panel - which meant the big lamp lit. So you'd cancel it. Until you used the handbrake - when it would come back on , as it was supposed to. But then stay on when you released the handbrake . . . meaning you had to cancel it again. I suppose I could have replaced the sensor - instead I relied on the dipstick and wired the LED to the oil pressure LED . . so they both came on when the ign switched on, but went out when it started . . .

And a Beta HPE took to turning it's lights off automatically. A slight problem in the outside lane of the M1N at night heading home from Sheffield and uni. A session of removing the fuse box, and unplugging and re-plugging every wire in the back of it between fuses and connectors to the main loom sorted it - cleaned all the contacts by unplugging/replugging.

And the engine earth lead on the 16V integrale in the piccies - suddenly took to just going "click" when starting . . . jump lead between body and engine porved the point - a new lead from under the battery to the engine and reliability resumed. Used to commute to work in Aachen, Germany for a year or so in that car.

I've had exactly the same sort issues on Triumphs, Renaults, Peugeots, Fords . . . it's just an old car thing.

One thing I wish I'd done with the integrale on the spit - I repaired it with my modified SIP Migmate, bought in 1992 to sort a HPE when the borrowed welder went back. After I'd finished it, I was struggling to weld some thin steel and thought sod it - and bought a new GYS . . . and now when I do a bit of welding, I looked around for anything else that needs welding . . . I've even been known to simply run a weld for no reason at all, other than it's pleasure to use and just turns out good welds that look good.

It was a bit of a breath in moment the first time I rolled it over . . .

Worked on it when I felt like it, didn't when I didn't. Back on the road last August.

Cranks are nitrided and it is indeed recommended not to regrind as you go through it - but Lancia sell undersized shells . . . Pretty confident mine is under-undersize now! Shame as someone in the past prepared it well. I have a spare N/A engine from a Thema (or something) sat in the shed with a hopefully good crank. I was so hacked off/depressed/fed up I bought a complete Fiat coupe engine from Martin at Deltaparts (known him for over 16yrs or so, so trust the engine is good). I've had to swop so much over between the two, I might as well bought a new crank and rebuilt my engine. Re-manufactured turbo coming next week - my 200,000 unit is rather worn!

I bought a 159 3.2 Q4 unseen on ebay as my stop gap. Needed something to tow with and missed the integrale - getting in and out of trialing field with a trailer behind with a car on is a little easier with all wheels driving. Had that 18mths and it needed the prop bearing doing - think I've mentioned that on here before.

Had a couple of electrical issues with italian cars - the 75 oil level sensor went up the creek - so it lit the LED on the check panel - which meant the big lamp lit. So you'd cancel it. Until you used the handbrake - when it would come back on , as it was supposed to. But then stay on when you released the handbrake . . . meaning you had to cancel it again. I suppose I could have replaced the sensor - instead I relied on the dipstick and wired the LED to the oil pressure LED . . so they both came on when the ign switched on, but went out when it started . . .

And a Beta HPE took to turning it's lights off automatically. A slight problem in the outside lane of the M1N at night heading home from Sheffield and uni. A session of removing the fuse box, and unplugging and re-plugging every wire in the back of it between fuses and connectors to the main loom sorted it - cleaned all the contacts by unplugging/replugging.

And the engine earth lead on the 16V integrale in the piccies - suddenly took to just going "click" when starting . . . jump lead between body and engine porved the point - a new lead from under the battery to the engine and reliability resumed. Used to commute to work in Aachen, Germany for a year or so in that car.

I've had exactly the same sort issues on Triumphs, Renaults, Peugeots, Fords . . . it's just an old car thing.

One thing I wish I'd done with the integrale on the spit - I repaired it with my modified SIP Migmate, bought in 1992 to sort a HPE when the borrowed welder went back. After I'd finished it, I was struggling to weld some thin steel and thought sod it - and bought a new GYS . . . and now when I do a bit of welding, I looked around for anything else that needs welding . . . I've even been known to simply run a weld for no reason at all, other than it's pleasure to use and just turns out good welds that look good.

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

Yes exactly like that

Sorta work at it same as you, do a bit when it suit but your 4 years seems decidedly speedy compared to my progress.

The worst is over but stuff keeps getting in the way.

Hasn't suited for a while but will get back to it shortly

Want to get it fully painted before the insects come out in force.

By coincidence it's the same paint code as the 75 so will get a bit of practice.

Did you ever do a built thread on your Evo?

Ive a pile of photos so should start one when I finish with the Alfa.

What GYS did you go for?

You are putting me in the notion!

Sorta work at it same as you, do a bit when it suit but your 4 years seems decidedly speedy compared to my progress.

The worst is over but stuff keeps getting in the way.

Hasn't suited for a while but will get back to it shortly

Want to get it fully painted before the insects come out in force.

By coincidence it's the same paint code as the 75 so will get a bit of practice.

Did you ever do a built thread on your Evo?

Ive a pile of photos so should start one when I finish with the Alfa.

What GYS did you go for?

You are putting me in the notion!

dobbslc

Member

- Messages

- 13,641

- Location

- Hertfordshire UK

I too had a SIP Migmate that was basicly junk! I treated myself to a GYS 140 easymig and instantly became a good welder!

Seriously the differece is massive.

PS don't blame us if your missus comes after you with a hammer when she finds out you've bought a new welder.......

Seriously the differece is massive.

PS don't blame us if your missus comes after you with a hammer when she finds out you've bought a new welder.......

Last edited by a moderator:

dobbslc

Member

- Messages

- 13,641

- Location

- Hertfordshire UK

Here's a link to my review.

http://www.mig-welding.co.uk/forum/threads/gys-easymig-140-review.71308/

http://www.mig-welding.co.uk/forum/threads/gys-easymig-140-review.71308/

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

Cheers dobbslc, thanks for the review.

The wife is very understanding (I suppose I could have worse vices and at least see knows where I am)

She doesn't give me a hard time which is just as well as I've been pretty out of control on the tool front recently.

You've now got me started looking.

Does the 140 only take 100mm roles? Ive no need for the 15kg rolls (they would be well rusted before I use them up) but normally I use 5kgs rolls.

Also if I need to weld something thick I get the stick welder out so don't need big power, (but I might change if the mig welder could weld thick sections)

I'm now going to have to go and try out a couple of welders.

Welders choice in Belfast stock GYS so I can try one out, but is anything else worth trying - Jasic?

Ive a real problem with tools

For years I didn't buy anything unless i really needed it, now I'm older I just go ahead and buy it or make a tool up.

My only saving grace is I'm not a tool snob. (the only snapon I have is a tool box and that was second hand)

Don't get me wrong I like good tools but for the use I give them there needs to be a good reason to spend more than I have to.

A better preforming tool for a little more money is a good reason.

I also find the for sale section on here pretty irresistible and I've got some great stuff.

Exuptoy, have you tried out any inverter Migs?

I haven't so have no idea how they weld, but value the opinion of people working on similar sorts of projects.

The wife is very understanding (I suppose I could have worse vices and at least see knows where I am)

She doesn't give me a hard time which is just as well as I've been pretty out of control on the tool front recently.

You've now got me started looking.

Does the 140 only take 100mm roles? Ive no need for the 15kg rolls (they would be well rusted before I use them up) but normally I use 5kgs rolls.

Also if I need to weld something thick I get the stick welder out so don't need big power, (but I might change if the mig welder could weld thick sections)

I'm now going to have to go and try out a couple of welders.

Welders choice in Belfast stock GYS so I can try one out, but is anything else worth trying - Jasic?

Ive a real problem with tools

For years I didn't buy anything unless i really needed it, now I'm older I just go ahead and buy it or make a tool up.

My only saving grace is I'm not a tool snob. (the only snapon I have is a tool box and that was second hand)

Don't get me wrong I like good tools but for the use I give them there needs to be a good reason to spend more than I have to.

A better preforming tool for a little more money is a good reason.

I also find the for sale section on here pretty irresistible and I've got some great stuff.

Exuptoy, have you tried out any inverter Migs?

I haven't so have no idea how they weld, but value the opinion of people working on similar sorts of projects.

What GYS did you go for?

A multipearl 200-2.

I knew I could weld to a reasonable degree as when I used work 3-phase "proper" weldlng plant, even as a design engineer, I could turn out a good looking, strong weld, time after time. But it was a bit hit and miss with the SIP - might do a whole day of good welding and come to it the day after and . . . Improved when I stuck a EUro torch on it, even better when I disconnected welding earth from mains earth (having melted the power cable to a my pillar drill on the same metal bench) and better still using decent wire and argoshield light rather than gasless wire.

But the from the first use, the GYS allowed me to produce good welds. Even with some crap wire that simply burnt back to the tip in the SIP.

A multipearl 200-2.

I knew I could weld to a reasonable degree as when I used work 3-phase "proper" weldlng plant, even as a design engineer, I could turn out a good looking, strong weld, time after time. But it was a bit hit and miss with the SIP - might do a whole day of good welding and come to it the day after and . . . Improved when I stuck a EUro torch on it, even better when I disconnected welding earth from mains earth (having melted the power cable to a my pillar drill on the same metal bench) and better still using decent wire and argoshield light rather than gasless wire.

But the from the first use, the GYS allowed me to produce good welds. Even with some crap wire that simply burnt back to the tip in the SIP.

dobbslc

Member

- Messages

- 13,641

- Location

- Hertfordshire UK

The wife is very understanding (I suppose I could have worse vices and at least see knows where I am)

She doesn't give me a hard time which is just as well as I've been pretty out of control on the tool front recently

That sounds like mine!

Pigeon_Droppings2

Member

- Messages

- 6,720

- Location

- london

I had a migmate too as a youngster...it's terrible for learning how to weld...15 years later I had another go at it and bought a Kemppi minarc....expensive but beautifully made and just fits in a cupboard. It's suitcase sized and weighs nothing...digital controls for materials and sizes means just set it to steel and set thickness and done....can then tweak the power and feed but most of the time the std settings work fine...I generally weld 0.8mm on Japan cars!

Migmate had those stupid power switches...what a faff.

Migmate had those stupid power switches...what a faff.

Exuptoy

Member

- Messages

- 3,144

- Location

- Maesteg, South Wales

I did pick up a small Tig inverter set a long time ago for a very good price but never tried an inverter MIG so cannot comment. This is the site to ask questions though!

My Porta cost me £650 from Steve (Weldequip) on here with a spot weld timer (which I've never used) and I wouldn't be without it now. It's a cracking set but so it should be for 600 quid I suppose. It does go down to 15 amps though which is exceptional apparently. This was a run weld on the rear quarter on a low setting on 0.6mm. Maybe a little too slow travel or slightly low power but no distortion.

My Porta cost me £650 from Steve (Weldequip) on here with a spot weld timer (which I've never used) and I wouldn't be without it now. It's a cracking set but so it should be for 600 quid I suppose. It does go down to 15 amps though which is exceptional apparently. This was a run weld on the rear quarter on a low setting on 0.6mm. Maybe a little too slow travel or slightly low power but no distortion.

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

Back on topic,

No wonder it takes so long to do anything, but every days a school day.

Last couple of patches to the drivers side inner guard -

Use a bit of copper to fill the gaps

Then attack it with a grinder and a spot blaster

A coat of Jotan 87

And finish it off with seam sealer and 3m stone-chip

I need to sort the front panel and reinstall the bonnet and wings before I can go any further with this side.

No wonder it takes so long to do anything, but every days a school day.

Last couple of patches to the drivers side inner guard -

Use a bit of copper to fill the gaps

Then attack it with a grinder and a spot blaster

A coat of Jotan 87

And finish it off with seam sealer and 3m stone-chip

I need to sort the front panel and reinstall the bonnet and wings before I can go any further with this side.