Migmac

Forum Supporter

- Messages

- 8,929

- Location

- Kintyre. Scotland

Good thought...wondering if just grease or some kind of dry lube would be best.

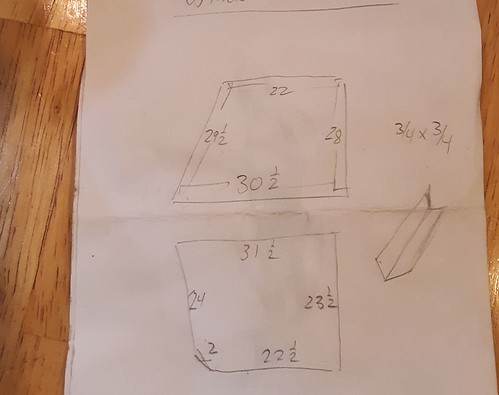

To design the bottom bracket, I put the thing on the lift....Welding upside down is not fun...as you guys well know! the lift at least helps with getting some distance between you and the weld spatter.....

I figured out what I wanted to do with the lower bracket and will be able to unbolt it at the end of the winter if need be. it took some time. I decided to use that 1/4 plate I bought a while back. glad I did.....

It took a couple of tries to get everything squared up and tacked, but once I had it where I wanted, it went fairly well...

and the bracket mostly finished. I still have to make a few relief cuts for parts of the frame and check the bolt holes, but Im happy with that....

tired...time to sleep!

thanks for lookin

JP

I just used grease, all I have

Steady on, we usually get the tail-end of your storms about 7-10 days later, but it's FAR too early on the year for that!

Steady on, we usually get the tail-end of your storms about 7-10 days later, but it's FAR too early on the year for that!