Hi. I recently finished a 12 week welding course ( hobby / interest, not accredited ) and thought i'd get myself a second hand mig.

I bought a Sip Migmate 150 as it had all the features i was looking for.

It was bought for one job by the pevious owner then put back in the box and left sitting for 5 years, it does look like new.

There was light rust on the reel of wire but i took off the top few layers and and it was shiney and new looking.

Tried using it today and had some issues.

No matter what setting i had it on the wire kept burning back and interrupting the wire feed. When i just pressed the trigger to feed wire it seemed to feed fine. As soon as i weld it just burns back.

I tried altering the stick out and gas flow (CO2), wire speed and power and the speed at which i moved the torch. Sometimes it would let me form a puddle and start to weld but eventually it would burn back.

It has a reasonably full 5KG reel of 0.6 wire and i have tightened the wheels of the motor down.

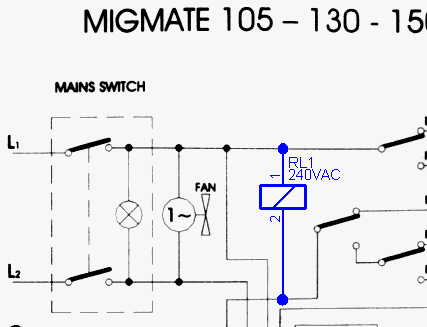

Power is high/ low on main switch then min/med/max on fine tune.

I had a good clean earth.

Metal was mild steel tubing 2mm thick.

Also when i removed the tip to inspect there was a small spring behind the tip that is now somewhere in my garden and i need a new one.

Is it my crap technique as the machines in college were much easier to use or is there something i should do with my set up/equipment?

I bought a Sip Migmate 150 as it had all the features i was looking for.

It was bought for one job by the pevious owner then put back in the box and left sitting for 5 years, it does look like new.

There was light rust on the reel of wire but i took off the top few layers and and it was shiney and new looking.

Tried using it today and had some issues.

No matter what setting i had it on the wire kept burning back and interrupting the wire feed. When i just pressed the trigger to feed wire it seemed to feed fine. As soon as i weld it just burns back.

I tried altering the stick out and gas flow (CO2), wire speed and power and the speed at which i moved the torch. Sometimes it would let me form a puddle and start to weld but eventually it would burn back.

It has a reasonably full 5KG reel of 0.6 wire and i have tightened the wheels of the motor down.

Power is high/ low on main switch then min/med/max on fine tune.

I had a good clean earth.

Metal was mild steel tubing 2mm thick.

Also when i removed the tip to inspect there was a small spring behind the tip that is now somewhere in my garden and i need a new one.

Is it my crap technique as the machines in college were much easier to use or is there something i should do with my set up/equipment?