You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lang lathe

- Thread starter HMB

- Start date

WorkshopChris

Member

- Messages

- 5,049

- Location

- South East Essex

Looks like a good set of kit providing you have 3 phase or a big enough converter should do all you can throw at it.

Screwdriver

Member

- Messages

- 10,991

That lathe is never going to be 2 tons. 650-750 kg about 3/4 of a tonne.

It does look like it should have a gap piece but I wouldn't be surprised if it never had one. Its a very short bed with a very long throw, a specialist lathe in other words. It would probably make 350 - 450 on eBay so 150 - 250 would be a reasonable offer to a mate.

When/if you are picking it up, take everything you can. Any odd bits, clamps, vices, angle blocks, stock - everything.

It does look like it should have a gap piece but I wouldn't be surprised if it never had one. Its a very short bed with a very long throw, a specialist lathe in other words. It would probably make 350 - 450 on eBay so 150 - 250 would be a reasonable offer to a mate.

When/if you are picking it up, take everything you can. Any odd bits, clamps, vices, angle blocks, stock - everything.

penfold

Ambassador plenipotentiary

- Messages

- 2,116

- Location

- Argyll and Bute, God's own country.

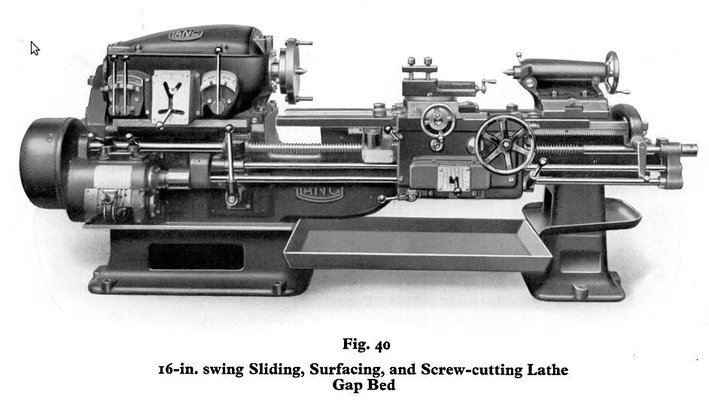

Even Lang Junior lathes weigh over a tonne; this isn't a Junior, it looks a lot like the 16".That lathe is never going to be 2 tons. 650-750 kg about 3/4 of a tonne.

It does look like it should have a gap piece but I wouldn't be surprised if it never had one. Its a very short bed with a very long throw, a specialist lathe in other words. It would probably make 350 - 450 on eBay so 150 - 250 would be a reasonable offer to a mate.

When/if you are picking it up, take everything you can. Any odd bits, clamps, vices, angle blocks, stock - everything.

Screwdriver

Member

- Messages

- 10,991

Even Lang Junior lathes weigh over a tonne; this isn't a Junior, it looks a lot like the 16".

View attachment 84119 View attachment 84120

OK. Can we nail this down a little:

Are you saying this is a six foot bed, eight feet or ten?

S.

<edit> TBH, looking at the two again, it could be the 6 foot machine. In which case it's a fecking HUGE lathe. And,as you suggest, on the heavy side!

WorkshopChris

Member

- Messages

- 5,049

- Location

- South East Essex

At a big guess, using that morse taper as a scale i would guess the bed is no more than 3 1/2 foot ish, maybe 4 with the gap piece fitted.

brightspark

Member

- Messages

- 41,586

- Location

- yarm stockton on tees

it will .quite common fitting it that way if theres no backplate to suit the headstockI am told that the 3jaw chuck fits into the 4 jaw but I'll be seeing it this week

WorkshopChris

Member

- Messages

- 5,049

- Location

- South East Essex

So only any use for holding smaller parts, your going to have to mess around with a DTI anyway so might as well just use the 4 jaw.

So only any use for holding smaller parts, your going to have to mess around with a DTI anyway so might as well just use the 4 jaw.

Yeah but you only need to set it up once if you're making 100 small parts, and an inaccurate chuck can be compensated for with the 4 jaw

brightspark

Member

- Messages

- 41,586

- Location

- yarm stockton on tees

that is very true providing all the parts u are making are all the same diameter and one jaw seems to be a few thou out .sometimes the wear is in the scroll so altering the settings it will need clocking up if a larger or smaller diameter is fitted inYeah but you only need to set it up once if you're making 100 small parts, and an inaccurate chuck can be compensated for with the 4 jaw

Absolutelythat is very true providing all the parts u are making are all the same diameter and one jaw seems to be a few thou out .sometimes the wear is in the scroll so altering the settings it will need clocking up if a larger or smaller diameter fitted in