You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 phase motor.

- Thread starter ukracer

- Start date

Spark plug

Member

- Messages

- 4,036

- Location

- Durham, England

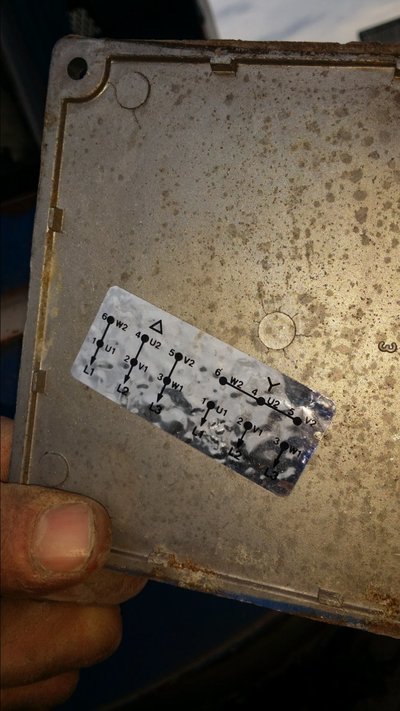

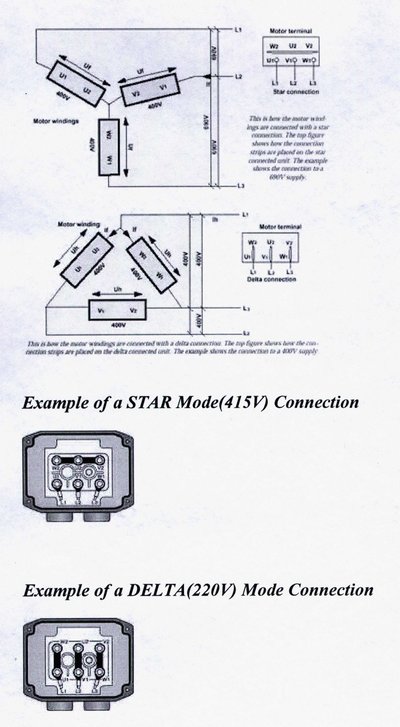

Looks like you need to wire the motor in delta configuration. Do this by moveing the jumper plates so they match up to the diagram next to the triangle symbol.

Edit: that is of course if your inverter has a 230v output.

Edit: that is of course if your inverter has a 230v output.

currently "STAR" 415 Volts 3 phase

if you change to wired in delta looks as if it may well pull in the region of 10.4 amps the trip on the starter is currently set in excess of this. in 415 Volts the plate says 6.4 amps so there was not much protection

whats the output on the Transwave, 415 or 220 Volts??

Stan

if you change to wired in delta looks as if it may well pull in the region of 10.4 amps the trip on the starter is currently set in excess of this. in 415 Volts the plate says 6.4 amps so there was not much protection

whats the output on the Transwave, 415 or 220 Volts??

Stan

WorkshopChris

Member

- Messages

- 4,987

- Location

- South East Essex

What is the overload set at in photo 4 i cant make it out from the photo. Motor data plate has 6 amps. Is this a new bit of kit to you or has it just developed a fault. If it's a new bit of kit might just need the overload adjusting to suit new supply. Can you put a clamp meter on it at startup.

good chance the inverter is 240v 3 phase not 415 (a lot are 240v, only expensive ones are 415)

so motor needs re-wiring into delta to match inverter

(check inverter to make sure this is right)

you see the little plates on the 3 right hand side motor connectors joining them together? take them off and turn them 90' so they join each connector to the connector on their left (fingers crossed they'll be 3 little plates there, their usually is unless someone's messed with it)

so motor needs re-wiring into delta to match inverter

(check inverter to make sure this is right)

you see the little plates on the 3 right hand side motor connectors joining them together? take them off and turn them 90' so they join each connector to the connector on their left (fingers crossed they'll be 3 little plates there, their usually is unless someone's messed with it)

OK guys. Thanks for all this. The motor 8s currently on an extra to fan for a blasting cabin.20 foot.

It powers the extraction.

The phase converter is a 4 hp transwave model. It works on other 3 phase kit.

The trip has a max of 10 amps. I think I am reading that the motor is pulling around 6.4

It's never been run by my mate but was supposed to be working. My mate does not have true 3 phase just the static inverter.

It's only going to cost around 200 to swap the motor for single phase .plus a new trip switch for single phase........but it's intrigued me now.

The housing the motor is under/in is big BUT it looks like the motor could have been overheating as the box on top actually blanks the air intakes on the end of the motor .

What intrigues me is is can I remember my school physics well enough.....if the voltage produced by the inverter is slightly too low would that cause the motor to pull more current to compensate? ???? Causing protection switch in the unit to trip

(the inverter does not trip or blow a fuse..) this is what's bugging me. Lol

It powers the extraction.

The phase converter is a 4 hp transwave model. It works on other 3 phase kit.

The trip has a max of 10 amps. I think I am reading that the motor is pulling around 6.4

It's never been run by my mate but was supposed to be working. My mate does not have true 3 phase just the static inverter.

It's only going to cost around 200 to swap the motor for single phase .plus a new trip switch for single phase........but it's intrigued me now.

The housing the motor is under/in is big BUT it looks like the motor could have been overheating as the box on top actually blanks the air intakes on the end of the motor .

What intrigues me is is can I remember my school physics well enough.....if the voltage produced by the inverter is slightly too low would that cause the motor to pull more current to compensate? ???? Causing protection switch in the unit to trip

(the inverter does not trip or blow a fuse..) this is what's bugging me. Lol

It's set at 10 when we are running it. If it's set lower than 10 it just trips quicker. And you confirm what I was reading that the motor is only 6What is the overload set at in photo 4 i cant make it out from the photo. Motor data plate has 6 amps. Is this a new bit of kit to you or has it just developed a fault. If it's a new bit of kit might just need the overload adjusting to suit new supply. Can you put a clamp meter on it at startup.

So far the only thing that makes real sense to me and my limited knowledge is the motor actually has a fault.......my mate does not have a meter but if anyone can post a suitable ebay link I am sure he would buy one...

Hello UKracer,

your terminology is misleading, is it an inverter drive or a rotary converter, which I believe the transwave is?

If an inverter variable frequency drive you must connect the motor directly to it , i.e. forget the starter and as most are 240v output reconnect the motor to delta.

If it's a rotary converter and it works others devices then that would seem to be OK, assuming a 415 ish output. Exactly what switch is tripping. Does your transwave have an output (load) current ammeter?

Re your physics, reduce voltage gives reduced current not more but with motors if the voltage is very low for the rated motor voltage it can pull more current depending on the motor load, this is because a motor also generates when running and this back EMF opposes the motor current.

Alec

your terminology is misleading, is it an inverter drive or a rotary converter, which I believe the transwave is?

If an inverter variable frequency drive you must connect the motor directly to it , i.e. forget the starter and as most are 240v output reconnect the motor to delta.

If it's a rotary converter and it works others devices then that would seem to be OK, assuming a 415 ish output. Exactly what switch is tripping. Does your transwave have an output (load) current ammeter?

Re your physics, reduce voltage gives reduced current not more but with motors if the voltage is very low for the rated motor voltage it can pull more current depending on the motor load, this is because a motor also generates when running and this back EMF opposes the motor current.

Alec

It's a transwave. NOT rotary. It's 415 volt out put and runs other 3 phase 415 gear just fine.

The motor is fitted into a 20 foot container (as an extractor system for sand blasting) and is prewired to the switches etc.

It "allegedly" was fine on purchase but my mate only has 240 single phase on site so needed a way to power it with 415 3 phase using and inverter.

http://www.powercapacitors.co.uk/wp...TC1_static_converters_literature_overview.pdf

It's the type on the left in light blue paint. I think it's the 3.0kw version.

You say don't use a starter if it's 240 volt VFD but does that also apply if it's 415 from a static converter?

Is that switch with a variable amp lever a starter??

The motor is fitted into a 20 foot container (as an extractor system for sand blasting) and is prewired to the switches etc.

It "allegedly" was fine on purchase but my mate only has 240 single phase on site so needed a way to power it with 415 3 phase using and inverter.

http://www.powercapacitors.co.uk/wp...TC1_static_converters_literature_overview.pdf

It's the type on the left in light blue paint. I think it's the 3.0kw version.

You say don't use a starter if it's 240 volt VFD but does that also apply if it's 415 from a static converter?

Is that switch with a variable amp lever a starter??

Spark plug

Member

- Messages

- 4,036

- Location

- Durham, England

Ok so as the static phase converter has a 415v output the motor is wired correctly.

So now I'm thinking the motor is drawing more current on start up due to being ran from the converter, which is causing the overload to trip. So you need to turn the overload up, ideally by measuring the curren with a clamp meter and setting the overload accordingly.

So now I'm thinking the motor is drawing more current on start up due to being ran from the converter, which is causing the overload to trip. So you need to turn the overload up, ideally by measuring the curren with a clamp meter and setting the overload accordingly.

AH so that is possible thenOk so as the static phase converter has a 415v output the motor is wired correctly.

So now I'm thinking the motor is drawing more current on start up due to being ran from the converter, which is causing the overload to trip. So you need to turn the overload up, ideally by measuring the curren with a clamp meter and setting the overload accordingly.

I think the previous poster confirmed my physics. Lol and if the inverter is giving less voltage that the motor expects/requires it tries to pull more Amps to compensate .

Biggest problem then now is the switch is adjusted to max. Which is 10 amps.

That was fine as the motor is 6 amps at 415 but I guess we are saying that it might need a 15 amp switch now until it gets up to full speed OR the phase converter is just too small for that motor.

Talking about clamp meters is a 25 quid on of ebay ok or does it HAVE to be a fluke?Ok so as the static phase converter has a 415v output the motor is wired correctly.

So now I'm thinking the motor is drawing more current on start up due to being ran from the converter, which is causing the overload to trip. So you need to turn the overload up, ideally by measuring the curren with a clamp meter and setting the overload accordingly.

WorkshopChris

Member

- Messages

- 4,987

- Location

- South East Essex

If i was to recommend a clamp meter for regular use then any from the fluke range, depending on features required but if i was looking for a basic meter for occasional use i thing it would probably be either.

http://uk.rs-online.com/web/p/produ...|prd|8937907&gclid=CNnT6bmQgcwCFfAy0wod_wMKrg

http://www.toolstation.com/shop/Ele...+Equipment/sd3348/Digital+Clamp+Tester/p61650

I have one very similar to the toolstation model it was the last one they stocked it performs well enough. But its ok in clamp mode,, but i wouldn't trust putting anything higher than 110v on the probes got better meters for that but as a 3rd meter to let me monitor all 3 lines at once its fine.

I have no connection with the RS one but i would trust that they have sourced and selected a safe and reliable product to put there name to.

http://uk.rs-online.com/web/p/produ...|prd|8937907&gclid=CNnT6bmQgcwCFfAy0wod_wMKrg

http://www.toolstation.com/shop/Ele...+Equipment/sd3348/Digital+Clamp+Tester/p61650

I have one very similar to the toolstation model it was the last one they stocked it performs well enough. But its ok in clamp mode,, but i wouldn't trust putting anything higher than 110v on the probes got better meters for that but as a 3rd meter to let me monitor all 3 lines at once its fine.

I have no connection with the RS one but i would trust that they have sourced and selected a safe and reliable product to put there name to.

WorkshopChris

Member

- Messages

- 4,987

- Location

- South East Essex

What is the correct name of this switch please

DOL Starter with overload (Direct On Load)

http://www.toolstation.com/shop/p53799?table=no

http://www.toolstation.com/shop/Ele...essories/sd3080/Thermal+Overload+Relay/p31837

they are about the best price around as far as i know.

Wedg1e

They call me Mr. Bodge-angles

- Messages

- 7,928

- Location

- Teesside, England

What is the correct name of this switch please.View attachment 82347 View attachment 82348

It's a DOL (Direct OnLine) starter.

It strikes me that 10 seconds is a long tiime for a motor to spin up to full RPM (and thus be still taking start-up current).

My mate has a 4-post lift and bought a TransWave to power its hydraulics; the pump wpuld barely try to start even though the rating of the TW was higher than the pump's motor. He did some research and found that it wasn't recommended by the makers for that purpose so he had to buy a humungous one which does now work... but it cost him a bomb.

Even cheap AC clamp meters are as accurate as you need; I have a £17 B&Q special that is within fractions of a percent of my AVO across its range (we do instrument calibration at work so easy to check). It's only if you need DC measurement that the price goes up.

WorkshopChris

Member

- Messages

- 4,987

- Location

- South East Essex

Just a quick through might be worth disconnecting the motor terminals and measure the resistance cross the windings. All 3 should be the same any deviation would indicate a possible motor problem.

Yeah I read that when I sourced my own converter. Especially lifts for some reason.It's a DOL (Direct OnLine) starter.

It strikes me that 10 seconds is a long tiime for a motor to spin up to full RPM (and thus be still taking start-up current).

My mate has a 4-post lift and bought a TransWave to power its hydraulics; the pump wpuld barely try to start even though the rating of the TW was higher than the pump's motor. He did some research and found that it wasn't recommended by the makers for that purpose so he had to buy a humungous one which does now work... but it cost him a bomb.

Even cheap AC clamp meters are as accurate as you need; I have a £17 B&Q special that is within fractions of a percent of my AVO across its range (we do instrument calibration at work so easy to check). It's only if you need DC measurement that the price goes up.

It might not be 10 seconds to be fair. I had my grandson with me who I was concentrating on but it sounded /felt like it had done the hard work of accelerating and was just reaching top speed sort of thing.

daleyd

Member

- Messages

- 10,421

- Location

- Wrexham, North Wales

If the full load current of the motor is 6 amps and your having to adjust the overload to 10 amps then there is something wrong, I'd suggest a clamp meter as above. No need for anything fancy, most cheapies will read close enough. Also what's the load on the motor, if it's got a lot of inertia then you can be limited by the number of starts (the windings get hot due to the starting current) , unlikely on a small motor but I've had overloads trip on large fans with a couple of starts in a row.

WorkshopChris

Member

- Messages

- 4,987

- Location

- South East Essex

If the full load current of the motor is 6 amps and your having to adjust the overload to 10 amps then there is something wrong, I'd suggest a clamp meter as above. No need for anything fancy, most cheapies will read close enough. Also what's the load on the motor, if it's got a lot of inertia then you can be limited by the number of starts (the windings get hot due to the starting current) , unlikely on a small motor but I've had overloads trip on large fans with a couple of starts in a row.

Spot on advise above, the overload on my dust extractor is correctly set to protect the motor.

If you turn it on it will run all day if it gets blocked it will trip.

But if you start it running then turn off, then re start without giving it a few min's in between it trips within seconds.