Franknstein

New Member

- Messages

- 29

- Location

- Milton Keynes, UK

Hi All

See my attached pics.

I removed a cylinder head from my 328i BMW the other day and one of the head bolts snapped. The block is aluminium and the head bolts steel. It snapped a couple of mm below the surface of the deck.

My plan is to weld a nut to it then try extract... if that method does not work, then I can grind flat and try and easy out etc..

I was after some advice welding this, even to ask if it can be done, as I am concerned I will melt the aluminium.

My thought was to take the top half of the broken head bolt, and machine it hollow, with a wall thickness of a couple mm, then chop it down to about 5mm tall. Then drop this little hollow cylinder piece into the hole sitting on top of the broken stud section, then fill it with weld... now it will sit proud of the head by a couple mm...

then drop a washer and m10 or larger nut on top and fill with weld again...

The theory is the little hollow cylinder should protect the threads from the arc.

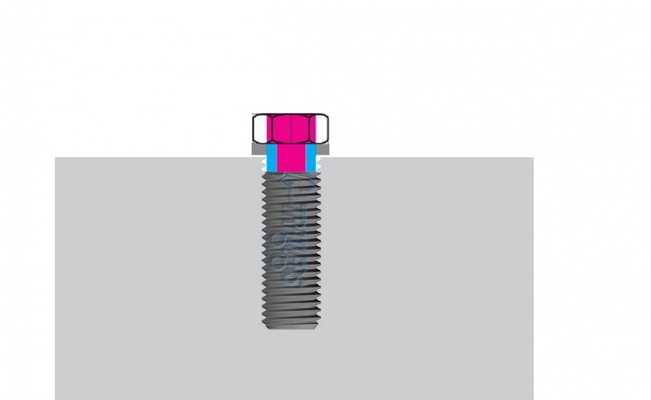

See my diagram. Blue is my hollow cylinder I will make from the other section of the head bolt, the pink is the weld, and the grey a washer.

I have a stick welder which I have welded a lot of stuff with. But I actually bought a GYS smartmig about a month back, but havent tried it yet! Should I try this with the stick or mig?

Any suggestions/thoughts/warnings appreciated.

thanks

See my attached pics.

I removed a cylinder head from my 328i BMW the other day and one of the head bolts snapped. The block is aluminium and the head bolts steel. It snapped a couple of mm below the surface of the deck.

My plan is to weld a nut to it then try extract... if that method does not work, then I can grind flat and try and easy out etc..

I was after some advice welding this, even to ask if it can be done, as I am concerned I will melt the aluminium.

My thought was to take the top half of the broken head bolt, and machine it hollow, with a wall thickness of a couple mm, then chop it down to about 5mm tall. Then drop this little hollow cylinder piece into the hole sitting on top of the broken stud section, then fill it with weld... now it will sit proud of the head by a couple mm...

then drop a washer and m10 or larger nut on top and fill with weld again...

The theory is the little hollow cylinder should protect the threads from the arc.

See my diagram. Blue is my hollow cylinder I will make from the other section of the head bolt, the pink is the weld, and the grey a washer.

I have a stick welder which I have welded a lot of stuff with. But I actually bought a GYS smartmig about a month back, but havent tried it yet! Should I try this with the stick or mig?

Any suggestions/thoughts/warnings appreciated.

thanks