On paper it should make things worse as around 2/3 of the total heat is at the +ve electrode i.e. for a given amperage etc you're putting more heat into the tungsten and less into the workI'd imagine the DCEP might give different results.

Oh ye....It didnt take long really to get a puddle maybe 10-15 seconds, although the puddle was very wide and flat. Doesnt seem to be much penetration through, when looking inside the box.

Its 50mm box, so looking at the pic, the bead looks about 10mm+ wide

Would have thought it'd take longer to get a pool. Bead width pretty much tallies with the little play i had today. My kit won't play ball with TIG DCEP (it thinks you're being daft and refuses to work) but out of curiousity i cranked the AC balance as far towards EP as it goes...

Material and wire are both 1.5mm 1050 Al

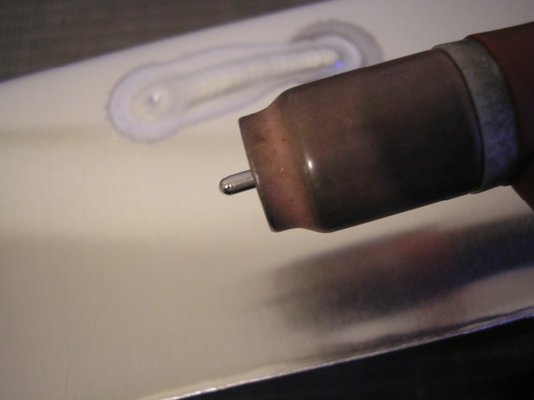

Tungsten is 2.4mm huntingdon fusion multistrike

68A and 60Hz throughout, i just floored the pedal waited for a weldpool and then shut off the arc after a short bead.

first two pics are tungsten before and after at 35% EN. Started counting after striking an arc, first 5 or 6 secs it was going nuts while the tungsten sorted itself out before stabilising enough to weld. Got to 13 before i had a weldpool that was stable and ready for some wire.

Front and back of beads. One on the left was @ 71%EN (i let the offcut cool back to ambient as it was a good excuse for a cuppa). Initially i tried to use the same tungsten but it wouldn't restrike, probably as the HF is set to min. You can see where the HF was going nuts. Changing HF settings is a bit of a ball ache so i swapped in another 2.4 prepped as in the first post. Weldpool took a couple secs to get going, much nicer and faster as you'd expect. Measuring across the toes the bead on the left ranges from 4-5mm while the one on the right is 7-9mm wide.

I think I might just throw my torch on the ground and get a desk job after seeing them

I think I might just throw my torch on the ground and get a desk job after seeing them

here...

here...  ). Me managing to cast a shadow over part of the pic didn't help things but the bead on left is cleaner/brighter. I put that down to the time taken for the weld with lots of EP. Weld ally with too long of an arc length or too slowly and welds typically come out duller just as with stainless etc

). Me managing to cast a shadow over part of the pic didn't help things but the bead on left is cleaner/brighter. I put that down to the time taken for the weld with lots of EP. Weld ally with too long of an arc length or too slowly and welds typically come out duller just as with stainless etc