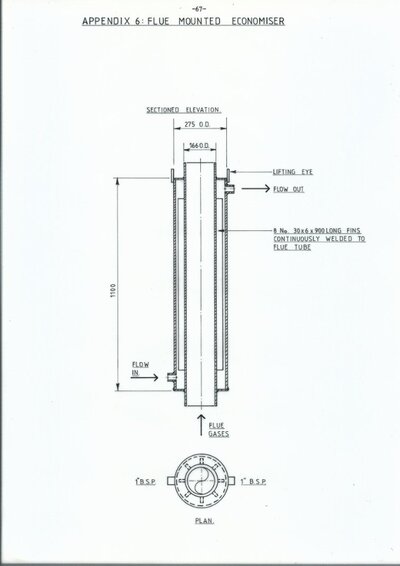

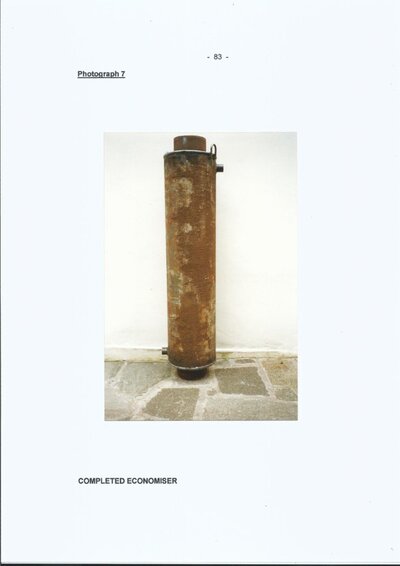

VanMarco, Back in 1999, I built a flue gas economiser (together with a load of other related things) as part of a study and dissertation that was produced for my MSc. This was fitted to a very simple on-farm bale burner which was used with all sorts of fuel (typical farmers shove in anything that can burn) so the fuel sourcse was very random and far from being of uniform calorific value and moisture content. Much of it was demolition waste. I've attached the details of the construction and photos of it. It was decided to go away from the multi tube type due to the problems of cleaning. The existing flue would get clogged due to heavy deposits which is something that you can't avoid when burning random waste . Cleaning was done by rods and brushes which was quick and easy - something you need when it's clogging in the middle of a cold spell. A multi flue economiser with the problems of making the end caps removeable for cleaning and also gas tight was looked at and excluded for day-to-day practicability.

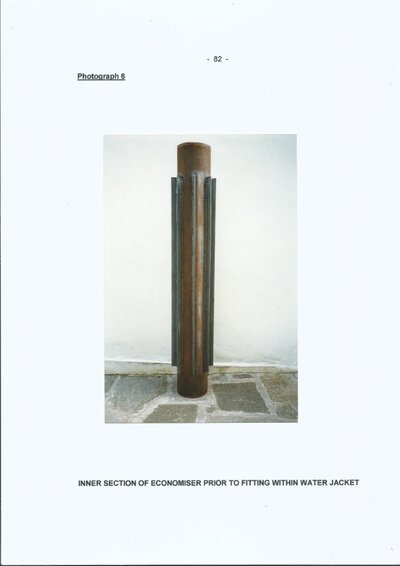

The chosen design doesn't hinder the flue cleaning in any way. The fins were fully welded to the flue tube to ensure maximum conductivity into the water and ensure good and even water distribution. The basic boiler prior to the installation of the economiser was as expected only about 30 % combustion efficient.

Tests after adding the economiser showed that at maximum operating conditions, i.e. good combustion maximum flue temp and low return water temperatures, the economiser could add an extra 18 kW of heat to the system (just over 50 % of the boiler capacity) so was a very effective way of upping its capacity and overall thermal efficiency. The flue gas temperatures were typically halved.

I also carried-out modifications to primary and secondary air plus some other things. All of these were tested and recorded and formed part of the dissertation. In short, a simply constructed economiser gave sufficient bennefits that the farmer kept it in place right up until the system was decomissioned few years ago .

Hopefully you will find this useful. I've loads more info from the tests on primary and secondary air etc but I won't bore you with those!

I'll post the economiser details in a while when I've dug them out.

The chosen design doesn't hinder the flue cleaning in any way. The fins were fully welded to the flue tube to ensure maximum conductivity into the water and ensure good and even water distribution. The basic boiler prior to the installation of the economiser was as expected only about 30 % combustion efficient.

Tests after adding the economiser showed that at maximum operating conditions, i.e. good combustion maximum flue temp and low return water temperatures, the economiser could add an extra 18 kW of heat to the system (just over 50 % of the boiler capacity) so was a very effective way of upping its capacity and overall thermal efficiency. The flue gas temperatures were typically halved.

I also carried-out modifications to primary and secondary air plus some other things. All of these were tested and recorded and formed part of the dissertation. In short, a simply constructed economiser gave sufficient bennefits that the farmer kept it in place right up until the system was decomissioned few years ago .

Hopefully you will find this useful. I've loads more info from the tests on primary and secondary air etc but I won't bore you with those!

I'll post the economiser details in a while when I've dug them out.