gaz1

Member

- Messages

- 20,530

- Location

- westyorkshire

you can improve it if you weld direct to a steel wood stove top

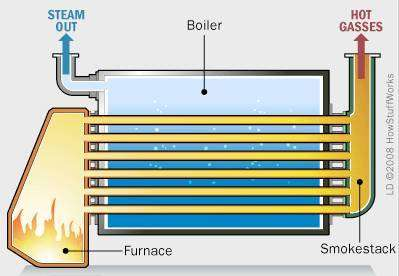

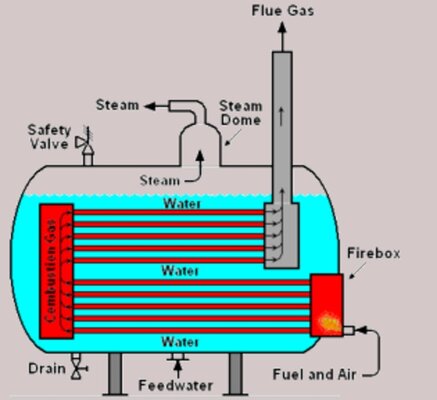

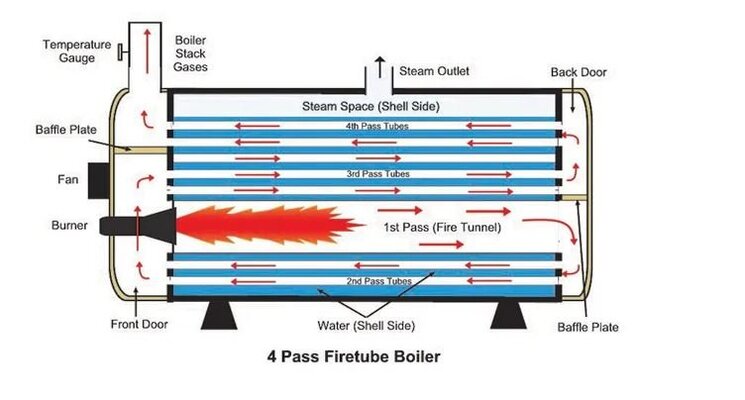

if your based on a normal wood stove and you come out of the rear you can then flow the fireboxes flue exhaust back to the front and up to the next level via tubes again before the final lift with the chimney

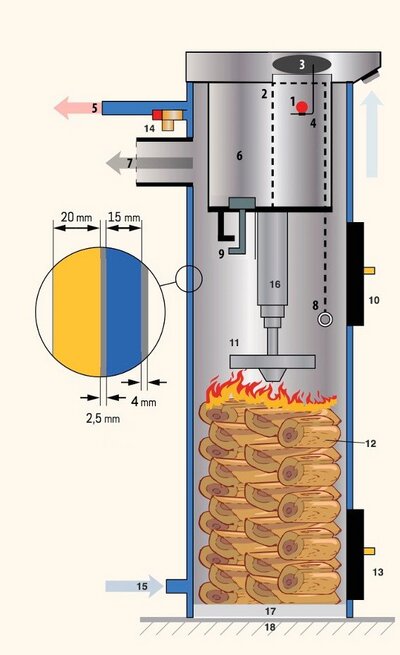

the pic is for a pellet boiler but can be used with a normal wood stove

for sizing of the tubes you have to match the stoves flue pipe so how many of your tubes equal the stoves flue size 5" or 6" should be about 7-8, 2" tubing

but you still need ash collection boxes at the rear of the stove so you can brush the steel tubes clean

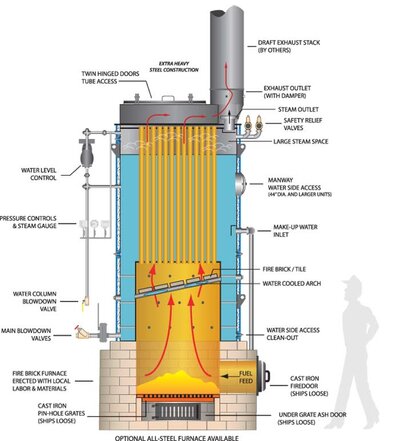

if your intending a seperate boiler you can connect it at the rear or from the top of the stove but you need your boiler stood above the fire stove

but it will chew through wood using secondary air will conserve on wood even more so if you preheat the secondary air released above the fire itself as it gasifys rather well and you burn this whist the stove is set at a lower level

if your based on a normal wood stove and you come out of the rear you can then flow the fireboxes flue exhaust back to the front and up to the next level via tubes again before the final lift with the chimney

the pic is for a pellet boiler but can be used with a normal wood stove

for sizing of the tubes you have to match the stoves flue pipe so how many of your tubes equal the stoves flue size 5" or 6" should be about 7-8, 2" tubing

but you still need ash collection boxes at the rear of the stove so you can brush the steel tubes clean

if your intending a seperate boiler you can connect it at the rear or from the top of the stove but you need your boiler stood above the fire stove

but it will chew through wood using secondary air will conserve on wood even more so if you preheat the secondary air released above the fire itself as it gasifys rather well and you burn this whist the stove is set at a lower level

thanks for the help!

thanks for the help!