You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

mot - joins on brake pipe?

- Thread starter steveo3002

- Start date

premmington

Member

- Messages

- 6,560

- Location

- Norfolk

I suppose it does save a good 12 pence using the female couplers

The reason people do it is - they put a single wall female flare on the harder steel pipe for the join and a bubble flare on the softer cooper replacement.

Double flaring old steel pipe and you get problems - the steel fractures and splits.

Single female flaring them is "bodgy" - but as an MOT tester - as long as does not leak and don't look twisted and it is well supported - its a pass mate...

premmington

Member

- Messages

- 6,560

- Location

- Norfolk

??

That's introducing galvanic corrosion into the mix also

It's only the brakes - what's the worst can happen?

Oh wait....

Yes you may be right - but what are you actually suggesting - not joining the pipes?

Even if you replace a whole brake pipe - from manufacturers joins - you still gonna get dissimilar metals next to each other.

Even if you use a female joiner with two male ends into it - you still gonna get dissimilar metals next to each other.

premmington

Member

- Messages

- 6,560

- Location

- Norfolk

Pretty sure i've seen male into female joins from the factory.

Can't remember where at the moment, might come to me later.....

Yeah they exist - from the factory.

JOEPRO

Member

- Messages

- 5,189

- Location

- UK

Yes you may be right - but what are you actually suggesting - not joining the pipes?

Even if you replace a whole brake pipe - from manufacturers joins - you still gonna get dissimilar metals next to each other.

Even if you use a female joiner with two male ends into it - you still gonna get dissimilar metals next to each other.

Also getting dissimilar metals at brake lines to calipers and other components.

The reason people do it is - they put a single wall female flare on the harder steel pipe for the join and a bubble flare on the softer cooper replacement.

Double flaring old steel pipe and you get problems - the steel fractures and splits.

Single female flaring them is "bodgy" - but as an MOT tester - as long as does not leak and don't look twisted and it is well supported - its a pass mate...

I haven't had problems double flaring steel pipe before but fair enough.

As noted by me and one other person on here so far, unfortunately in NI the testers will fail a car with a female flare on a brake line.

Has to be the double male coupling. Works for me, have a box of them and wouldn't use female flares as I personally see zero advantage and see it as a weak joint depending on a single wall flare to not split or work harden over time.

Nothing else to add to this - just passing on info for what is required in NI.

Melvyn Best

Member

- Messages

- 1,938

- Location

- Cambridge

Does that mean they will fail cars on their first test that come out of the factory made that way??Also getting dissimilar metals at brake lines to calipers and other components.

I haven't had problems double flaring steel pipe before but fair enough.

As noted by me and one other person on here so far, unfortunately in NI the testers will fail a car with a female flare on a brake line.

Has to be the double male coupling. Works for me, have a box of them and wouldn't use female flares as I personally see zero advantage and see it as a weak joint depending on a single wall flare to not split or work harden over time.

Nothing else to add to this - just passing on info for what is required in NI.

If you want to make a really nice looking job of it, as per Joepro's above, the pipe straightener really is essential.

I made one myself from some ally angle, a dozen bearings and some turned sleeves for the bearings. My advice to anyone else would be just buy one They weren't £20 when I made mine, more like £50. I tried it with just the bearings to start with and it put facets on the OD of the pipe, but I'd sunk enough time at that point that it was worth making the semicircular sleeves for the bearings. It really does improve the finish of the job no end though.

They weren't £20 when I made mine, more like £50. I tried it with just the bearings to start with and it put facets on the OD of the pipe, but I'd sunk enough time at that point that it was worth making the semicircular sleeves for the bearings. It really does improve the finish of the job no end though.

As for galvanic corrosion, it only occurs in the presence of an electrolyte. An assembled joint is gas tight. I wouldn't worry about any corrosion on the sealing faces.

I made one myself from some ally angle, a dozen bearings and some turned sleeves for the bearings. My advice to anyone else would be just buy one

They weren't £20 when I made mine, more like £50. I tried it with just the bearings to start with and it put facets on the OD of the pipe, but I'd sunk enough time at that point that it was worth making the semicircular sleeves for the bearings. It really does improve the finish of the job no end though.

They weren't £20 when I made mine, more like £50. I tried it with just the bearings to start with and it put facets on the OD of the pipe, but I'd sunk enough time at that point that it was worth making the semicircular sleeves for the bearings. It really does improve the finish of the job no end though.As for galvanic corrosion, it only occurs in the presence of an electrolyte. An assembled joint is gas tight. I wouldn't worry about any corrosion on the sealing faces.

I was going toIf you want to make a really nice looking job of it, as per Joepro's above, the pipe straightener really is essential.

I made one myself from some ally angle, a dozen bearings and some turned sleeves for the bearings. My advice to anyone else would be just buy oneThey weren't £20 when I made mine, more like £50. I tried it with just the bearings to start with and it put facets on the OD of the pipe, but I'd sunk enough time at that point that it was worth making the semicircular sleeves for the bearings. It really does improve the finish of the job no end though.

I wish I'd thought of the clamps for matching existing pipes

JOEPRO

Member

- Messages

- 5,189

- Location

- UK

I'm think my old Pug 106 has them under the seat area to join pipes.Pretty sure i've seen male into female joins from the factory.

Can't remember where at the moment, might come to me later.....

As for galvanic corrosion - has nobody had a car old enough to struggle to remove bleed nipples or tube nuts from calipers?

I got to the point I would swap bleed nipples, fully greased up, every year, just to avoid the issue occuring.

Trying brass at the moment . . . but that's got concerns too.

I got to the point I would swap bleed nipples, fully greased up, every year, just to avoid the issue occuring.

Trying brass at the moment . . . but that's got concerns too.

I have struggled to remove bleed nipples, but galvanic corrosion wasn't the cause. That was allsorts of road grime making its way down the hole in the nipple and rusting the nipple to the taper in the caliper. I thought I was winning when I got the nipple loose without breaking it, but the crap stuck to it tore out the thread in the caliper as I unscrewed it. There's a reason for the rubber caps that many people seem to casually discard....

premmington

Member

- Messages

- 6,560

- Location

- Norfolk

Does that mean they will fail cars on their first test that come out of the factory made that way??

NI test should be the same as a UK test - NI is England....

They just got problems with thruput - Maha ramps with welds cracking - not letting family run business do the testing from the outset - then wanting them to do it...

Oh yeah - I got a good handle on the motortrade in NI - I have dear friend who trades there and I visit allot....

If you wanted to design a system to promote corrosion, you wouldn't go far wrong designing a bleed nipple. The seal is on the end face and while the threads are tight, the centre drilling allows (salt laden) moisture right to the back of the thread and also allows airflow out from the back to promote water wicking right down the thread.

When I rebuilt my MX5 calipers, I made stainless bleed nipples and fitted them with lashings of red rubber grease on the threads. So far, so good.

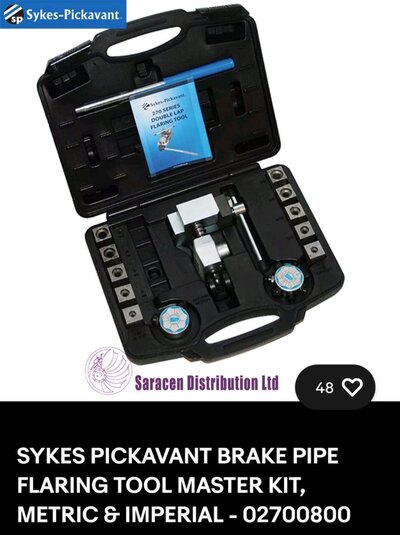

For flaring, I've got a kit that came from Frost that has SAE and DIN tooling in a case but it looks like they only sell them as singles now. SAE and DIN. I used a machine mart set for years before that on copper, kunifer and steel, but the tube clamp marked the tube wall and getting the pipe length right and flared square was fussy. The Frost kit (or wherever you get it from) just works and doesn't leave any marks on the pipe. I use a BS2 or 3 centre drill to deburr the pipe after cutting with a tubing cutter, any burrs really throw the machine mart style tools off.

I used a bender like this for all the pipes on my Dad's Cavalier project ^

When I rebuilt my MX5 calipers, I made stainless bleed nipples and fitted them with lashings of red rubber grease on the threads. So far, so good.

For flaring, I've got a kit that came from Frost that has SAE and DIN tooling in a case but it looks like they only sell them as singles now. SAE and DIN. I used a machine mart set for years before that on copper, kunifer and steel, but the tube clamp marked the tube wall and getting the pipe length right and flared square was fussy. The Frost kit (or wherever you get it from) just works and doesn't leave any marks on the pipe. I use a BS2 or 3 centre drill to deburr the pipe after cutting with a tubing cutter, any burrs really throw the machine mart style tools off.

I used a bender like this for all the pipes on my Dad's Cavalier project ^

keithski122

Member

- Messages

- 2,064

I had a mot advisory for grease on my brake pipes....................it was the mot tester who greased them about four years ago!Coat of underseal sploshed on top.

Sorted.

I went for AN-3 coated stainless braided Teflon hose when I did my last car, pipes run in cabin.

Two lengths from Master cylinder to rear bias valves, then a bulkhead fitting through wheel bucket and another line to rear calipers.

Front lines are one piece from Master Cylinder to caliper(s).

Kept the diagonal split for safety.

Two lengths from Master cylinder to rear bias valves, then a bulkhead fitting through wheel bucket and another line to rear calipers.

Front lines are one piece from Master Cylinder to caliper(s).

Kept the diagonal split for safety.

doubleboost

Member

- Messages

- 3,941

- Location

- Newcastle upon Tyne England

Very tidy a credit to you those pipesIf you want to make a really nice looking job of it, as per Joepro's above, the pipe straightener really is essential.

I made one myself from some ally angle, a dozen bearings and some turned sleeves for the bearings. My advice to anyone else would be just buy oneThey weren't £20 when I made mine, more like £50. I tried it with just the bearings to start with and it put facets on the OD of the pipe, but I'd sunk enough time at that point that it was worth making the semicircular sleeves for the bearings. It really does improve the finish of the job no end though.

As for galvanic corrosion, it only occurs in the presence of an electrolyte. An assembled joint is gas tight. I wouldn't worry about any corrosion on the sealing faces.

View attachment 487907