Blue Chips

Forum Supporter

- Messages

- 759

- Location

- Maine, USA

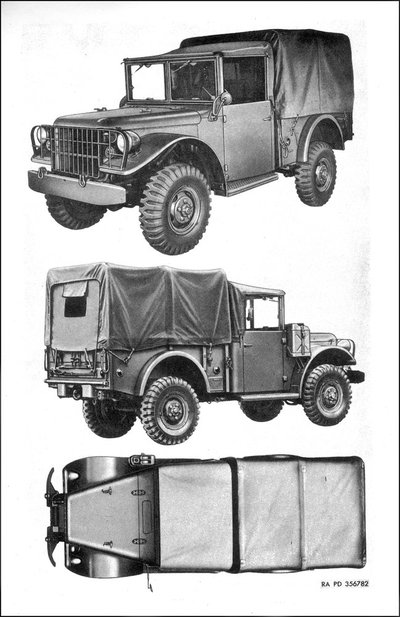

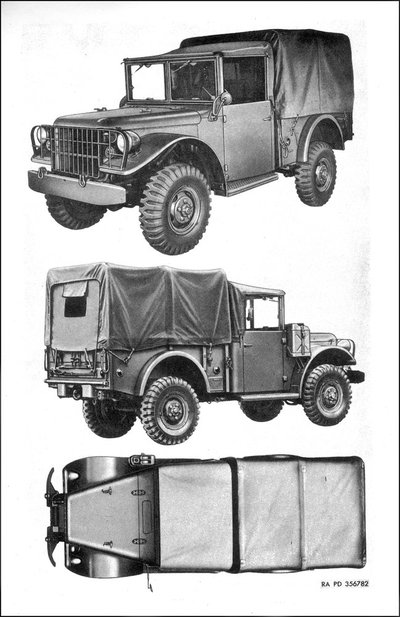

I've started work again on my 1954 Dodge M37 3/4-ton military cargo truck restoration project. Since this will be an ongoing project, I've started a new thread for it. I've had the M37 stashed away in a shipping container for a number of years, and now it's residing in a storage unit a short distance from our house in Brunswick. I've removed most of the body parts to do a semi-frame-off restoration (everything but the cab), and the parts are all in the storage unit. The thumbnails below show the current state of the M37 and what it should look like if/when it's done. I don't know if I'll stay with the canvas cab top or find a metal or fiberglass hard top for it.

We are currently in the planning stage for building a second two-car garage, but until that's built, I'll have to keep the M37 in the storage unit. I don't think I'm allowed to work on vehicles in the rented storage unit, but that doesn't preclude me from working on various components that I can carry back and forth between the storage unit and my workshop.

To get the momentum going again on this project, I thought I'd start by working on the brake system. I already replaced/rebuilt all of the brake components for all four wheels some time ago (see below) at the same time that I overhauled the hubs and wheels/rims, so that much of the brake system is done. BTW, I went to a lot of trouble to find five rims and split rings that were in very good or NOS condition, which I then sandblasted, primed, and painted. Here are a few photos of the brakes and wheels.

A few days ago, I brought the frame member that holds the brake master cylinder (the cylinder is mounted under the floor of the cab) over to my workshop. The original master cylinder was in a rebuildable condition, but as a safety upgrade I've decided to convert the brakes to a two-circuit (front-rear) system, using a tandem master cylinder. Shown below is the old master cylinder after cleaning it up. Notice that it has a valve and fitting that connects to a tube that vents the reservoir to the engine's air intake system as part of the vehicles deep-water fording setup. With a fording (snorkel) kit installed, the M37 could ford water up to 84 inches deep! However, I'm not planning on doing any deep-water fording, so the replacement master cylinder doesn't need a fording vent.

I found a new tandem master cylinder that was used on, IIRC, a late Dodge WM300 Power Wagon, which had the same front and rear drum brakes, wheels, axles, etc., as the M37, and the cylinder bore is the same as the original M37 master cylinder bore (1-1/4"). I plan to add a pressure-differential valve/switch (NOT a proportioning valve) to warn of any front or rear system failure.

The main difference as far as installation goes, is that the original master cylinder had a three-bolt mount, whereas the tandem master cylinder is a two-bolt mount, so I had to alter the frame member a bit by drilling two new mounting holes, and just because I like to over-engineer things a bit, I fabricated two adapter plates. The new master cylinder has to be mounted with its mounting boss almost touching the mounting flange of the frame member, and because there is some radius in the bend of that mounting flange, I made one plate with a radiused edge to conform to the flange bend radius. That allowed me to avoid having to grind a radius into the master cylinder mounting boss. I made the other adapter plate as a backing/reinforcing plate, simply because I wanted to make sure that the frame member didn't lose any strength from the extra mounting holes, but instead would actually gain some additional strength from the plates.

Here are the two adapter plates that I fabricated (one is 3/32" thick and the other is 1/4" thick):

The images below show the frame member with the adapter plates attached, after sandblasting, priming with self-etching primer, and painting in Marine Corps green alkyd enamel. BTW, the weld is not mine; it's the original weld.

I tried the new tandem master cylinder for fit. So far so good. It won't be permanently mounted until after the frame member is reinstalled on the truck.

I plan to continually update this thread as I progress on the project.

We are currently in the planning stage for building a second two-car garage, but until that's built, I'll have to keep the M37 in the storage unit. I don't think I'm allowed to work on vehicles in the rented storage unit, but that doesn't preclude me from working on various components that I can carry back and forth between the storage unit and my workshop.

To get the momentum going again on this project, I thought I'd start by working on the brake system. I already replaced/rebuilt all of the brake components for all four wheels some time ago (see below) at the same time that I overhauled the hubs and wheels/rims, so that much of the brake system is done. BTW, I went to a lot of trouble to find five rims and split rings that were in very good or NOS condition, which I then sandblasted, primed, and painted. Here are a few photos of the brakes and wheels.

A few days ago, I brought the frame member that holds the brake master cylinder (the cylinder is mounted under the floor of the cab) over to my workshop. The original master cylinder was in a rebuildable condition, but as a safety upgrade I've decided to convert the brakes to a two-circuit (front-rear) system, using a tandem master cylinder. Shown below is the old master cylinder after cleaning it up. Notice that it has a valve and fitting that connects to a tube that vents the reservoir to the engine's air intake system as part of the vehicles deep-water fording setup. With a fording (snorkel) kit installed, the M37 could ford water up to 84 inches deep! However, I'm not planning on doing any deep-water fording, so the replacement master cylinder doesn't need a fording vent.

I found a new tandem master cylinder that was used on, IIRC, a late Dodge WM300 Power Wagon, which had the same front and rear drum brakes, wheels, axles, etc., as the M37, and the cylinder bore is the same as the original M37 master cylinder bore (1-1/4"). I plan to add a pressure-differential valve/switch (NOT a proportioning valve) to warn of any front or rear system failure.

The main difference as far as installation goes, is that the original master cylinder had a three-bolt mount, whereas the tandem master cylinder is a two-bolt mount, so I had to alter the frame member a bit by drilling two new mounting holes, and just because I like to over-engineer things a bit, I fabricated two adapter plates. The new master cylinder has to be mounted with its mounting boss almost touching the mounting flange of the frame member, and because there is some radius in the bend of that mounting flange, I made one plate with a radiused edge to conform to the flange bend radius. That allowed me to avoid having to grind a radius into the master cylinder mounting boss. I made the other adapter plate as a backing/reinforcing plate, simply because I wanted to make sure that the frame member didn't lose any strength from the extra mounting holes, but instead would actually gain some additional strength from the plates.

Here are the two adapter plates that I fabricated (one is 3/32" thick and the other is 1/4" thick):

The images below show the frame member with the adapter plates attached, after sandblasting, priming with self-etching primer, and painting in Marine Corps green alkyd enamel. BTW, the weld is not mine; it's the original weld.

I tried the new tandem master cylinder for fit. So far so good. It won't be permanently mounted until after the frame member is reinstalled on the truck.

I plan to continually update this thread as I progress on the project.

I could do with a burger right now.

I could do with a burger right now.