Sergei Slovenija

Member

- Messages

- 1,267

- Location

- Slovenija Ljubljana

Raptor day.

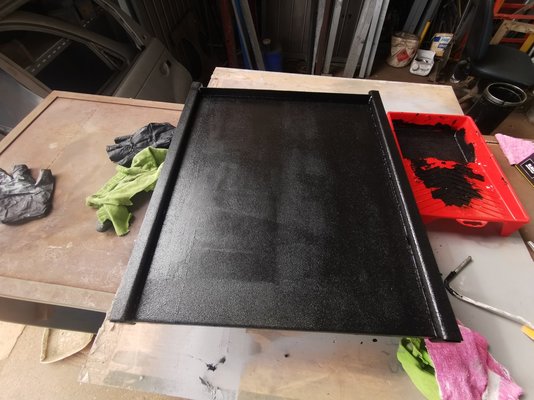

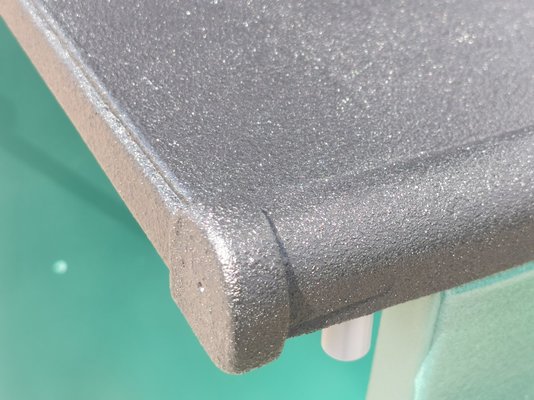

So, all the drawers were sanded and coated with a 2K epoxy primer. Two types of Raptor polyurea coating were tested. Spray-packed on the top of the chest and applied with a roller on the shelves (package in a bottle). I covered half of one shelf with a homemade compound (adding 10% UHMWPE-g graft powder). After the final polymerization, I expect the effect of "sandpaper" and increased abrasive resistance. 2K polyurea itself is strong, we will strengthen it with a polymer from another opera. The spray is very foamy, and the can was barely enough for an area of less than 0.8 m2. I will repaint and increase the thickness of the layer, using a roller, with a Raptor for manual application.

![IMG_20220704_171330748_HDR[1].jpg IMG_20220704_171330748_HDR[1].jpg](https://www.mig-welding.co.uk/forum/data/attachments/350/350539-e2a1e5ac770c02b54a1f098fef215830.jpg?hash=4qHlrHcMAr)

.

.

it'a about 40mm out of square and 30 mil ish wider in the middle than the two ends . I now need another1/2 sheet of ply because of the cuts . In between the wind and the rain I've stripped it all and plyed all bar the last bit . tomorrow facias and drip . they'll be fun as all the timber to the perimeter have been cut sort ! Instead of doing the roof level and then firings jack built the roof on a slope with a 90 mil drop end to end it'been a ba****d

it'a about 40mm out of square and 30 mil ish wider in the middle than the two ends . I now need another1/2 sheet of ply because of the cuts . In between the wind and the rain I've stripped it all and plyed all bar the last bit . tomorrow facias and drip . they'll be fun as all the timber to the perimeter have been cut sort ! Instead of doing the roof level and then firings jack built the roof on a slope with a 90 mil drop end to end it'been a ba****d