BChild

SIP - enough with the mods!!!!

- Messages

- 1,023

just adding to this, almost gone to the wall thread.

pretty much gone to the wall indeed

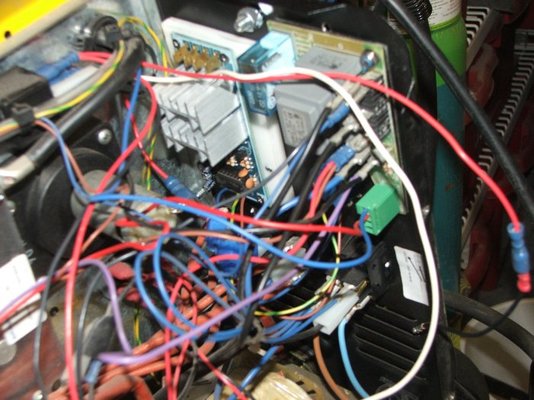

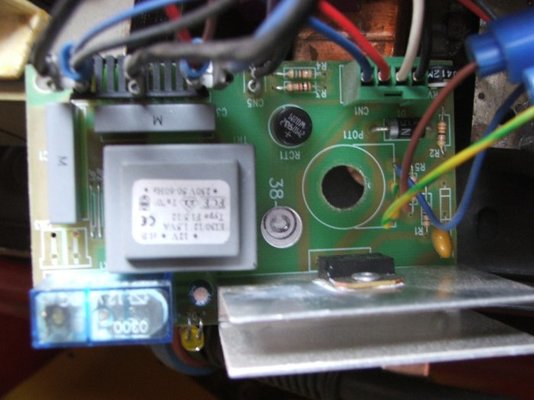

pretty much gone to the wall indeedto everyone thinking about this... do it properly fit a PWM controller, and a transformer... use the normal control circuitry to supply your brake switching relay. doing it this way you'll not suffer any variations on motor speed, you'll have precise control from the pot controlling the PWM circuit and thus wire speed. welding will become so much more relaible.

Plucking up the courage to do it.......

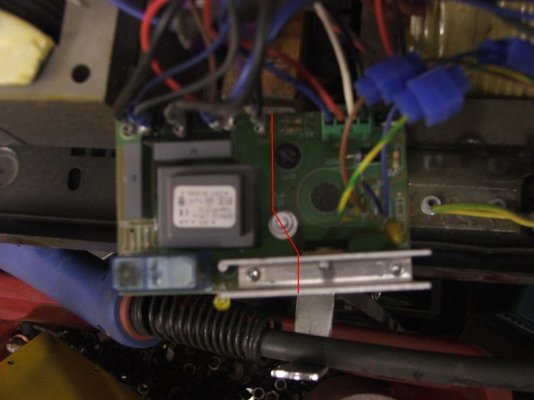

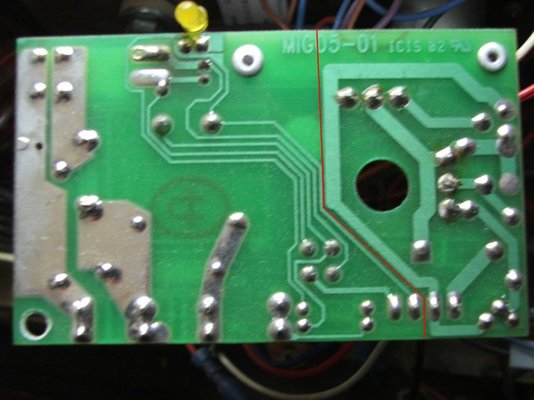

) is the 24V feed to the PWM as it needs to be controlled same as the gas solenoid I fitted when I converted the machine to euro torch - in fact that's almost a plan! FLW!!!!!

) is the 24V feed to the PWM as it needs to be controlled same as the gas solenoid I fitted when I converted the machine to euro torch - in fact that's almost a plan! FLW!!!!!