Dishing stump, again.

There was another thread on here today discussing routers. I remembered I had one in the garage so dragged it out to tidy up my shoddy woodwork. It is rarely used. My router bit selection is pretty limited (Aldi special buys!) and I didn't have anything that would tidy the bottom of the dish, but the circumference cleaned up pretty nicely.

It's fairly circular for cutting by hand to a line, and the diameter has gone up to about 4 and three quarter inches. It doesn't sound a lot, but the area increase is very noticeable.

I thought I'd a have a go with this planishing hammer to smooth out all the bumps from yesterday. I didn't persevere very long. The hammer is very noisy. It is currently powered by a 24litre direct drive compressor which kicks in after about 10 seconds of use. Double the annoyance.

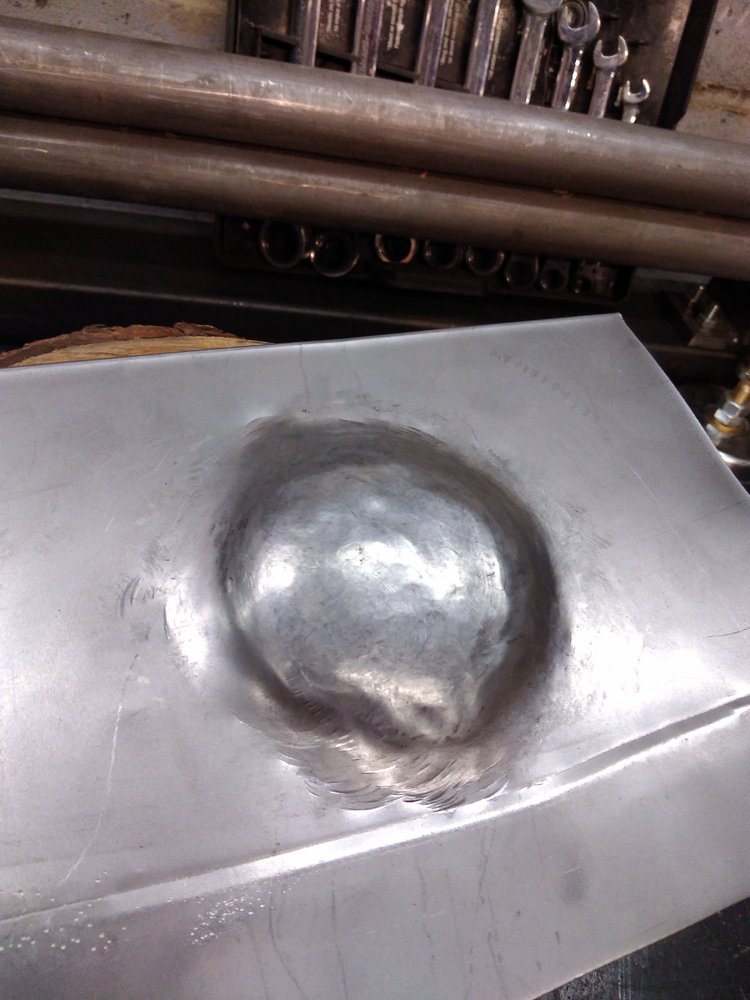

There's a bit of a knack to working the metal which I haven't picked up yet. I got the sheet looking fairly smooth and nice and then promptly hammered the crown flat. I think that the problem was that I didn't apply enough downward pressure with my hands to keep the metal stretched and the crown in shape. I made a little effort trying to rescue it but I think I've stretched the metal a bit too much so I packed in. Notice all the hammer marks around the edges too. Deffo something wrong there. It's a little less lumpy than yesterday. Probably wouldn't take long to get a reasonable finish.

There was another thread on here today discussing routers. I remembered I had one in the garage so dragged it out to tidy up my shoddy woodwork. It is rarely used. My router bit selection is pretty limited (Aldi special buys!) and I didn't have anything that would tidy the bottom of the dish, but the circumference cleaned up pretty nicely.

It's fairly circular for cutting by hand to a line, and the diameter has gone up to about 4 and three quarter inches. It doesn't sound a lot, but the area increase is very noticeable.

I thought I'd a have a go with this planishing hammer to smooth out all the bumps from yesterday. I didn't persevere very long. The hammer is very noisy. It is currently powered by a 24litre direct drive compressor which kicks in after about 10 seconds of use. Double the annoyance.

There's a bit of a knack to working the metal which I haven't picked up yet. I got the sheet looking fairly smooth and nice and then promptly hammered the crown flat. I think that the problem was that I didn't apply enough downward pressure with my hands to keep the metal stretched and the crown in shape. I made a little effort trying to rescue it but I think I've stretched the metal a bit too much so I packed in. Notice all the hammer marks around the edges too. Deffo something wrong there. It's a little less lumpy than yesterday. Probably wouldn't take long to get a reasonable finish.