You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reamers

- Thread starter MattF

- Start date

Kram

Member

- Messages

- 8,371

- Location

- Sussex

Yes I have two sets from amazon, they were £5 for a 3-12mm H7 set and £7 for a 3-10mm H8 set which I havent used yet.

H7 is generally +0.2mm, so clearance holes.

H8 is close fit.

The h7 holes measure good with the ball gauges, in my opinion. Wouldnt want to rely on them for anything safety critical but remember its a £5 set rather than £15+ each that the branded ones cost. Ive got a few branded ones, they cost £10 each used.

H7 is generally +0.2mm, so clearance holes.

H8 is close fit.

The h7 holes measure good with the ball gauges, in my opinion. Wouldnt want to rely on them for anything safety critical but remember its a £5 set rather than £15+ each that the branded ones cost. Ive got a few branded ones, they cost £10 each used.

Have you got a link to them on amazon please?Yes I have two sets from amazon, they were £5 for a 3-12mm H7 set and £7 for a 3-10mm H8 set which I havent used yet.

H7 is generally +0.2mm, so clearance holes.

H8 is close fit.

The h7 holes measure good with the ball gauges, in my opinion. Wouldnt want to rely on them for anything safety critical but remember its a £5 set rather than £15+ each that the branded ones cost. Ive got a few branded ones, they cost £10 each used.

Kram

Member

- Messages

- 8,371

- Location

- Sussex

Heres the links, not available from the same seller and tbe second price has gone up. It took quite a bit of searching to find the H8 set.

www.amazon.co.uk/gp/aw/d/B07V4747BW

www.amazon.co.uk/gp/aw/d/B07VWVH8XL

www.amazon.co.uk/gp/aw/d/B07V4747BW

www.amazon.co.uk/gp/aw/d/B07VWVH8XL

MattF

Forum Supporter

- Messages

- 18,336

- Location

- South Yorkshire

Yes I have two sets from amazon, they were £5 for a 3-12mm H7 set and £7 for a 3-10mm H8 set which I havent used yet.

H7 is generally +0.2mm, so clearance holes.

H8 is close fit.

The h7 holes measure good with the ball gauges, in my opinion. Wouldnt want to rely on them for anything safety critical but remember its a £5 set rather than £15+ each that the branded ones cost. Ive got a few branded ones, they cost £10 each used.

Which would be preferred for reaming out a bronze bush for a rotating shaft; H7 or H8?

Brad93

Member

- Messages

- 19,423

- Location

- Essex, United Kingdom

H8Which would be preferred for reaming out a bronze bush for a rotating shaft; H7 or H8?

MattF

Forum Supporter

- Messages

- 18,336

- Location

- South Yorkshire

I suppose really you need to measure your shaftand see what the tolerance is.

it it Oilite or Phosphor Bronze. Oil or grease lubrication?

Oil lube. Not got the shaft here as yet.

Kram

Member

- Messages

- 8,371

- Location

- Sussex

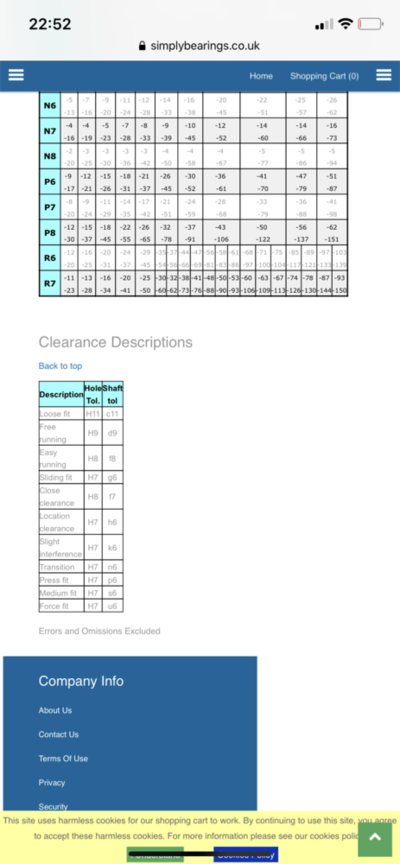

I dont claim to understand the ISO fits system, but most of them seem wrong (not your chart, the system!), example being force fits, why would you have a +0.2mm hole for a force fit as it means you need a +0.25mm shaft. Please can someone explain it with an example or two.

addjunkie

Member

- Messages

- 14,306

- Location

- Northumberland. Reet oot in the sticks

It only works if you make both pieces to the correct tolerences. Its in the zeus book. So the fit would be something like H7G6 denoting two parts.I dont claim to understand the ISO fits system, but most of them seem wrong (not your chart, the system!), example being force fits, why would you have a +0.2mm hole for a force fit as it means you need a +0.25mm shaft. Please can someone explain it with an example or two.

Hole And Shaft Basis Limits and Fits,Hole Limits And Fits,Hole And Shaft,Tolerance,

Hole And Shaft Basis Limits and Fits,Limits and Holes,hole,limits,fit,Iso Tolerance,ISO tolerance system, Free Running,Loose Running,Sliding,Easy Runing, Locational Clerance, Locatinal Transition,Force Fit, Medium Runing,Engineering,Coban Engineering,

Agroshield

Member

- Messages

- 6,390

...the fit would be something like H7G6 denoting two parts.

It is also a system where you have to be very, very careful when writing things down. It also makes oral communication difficult. The capitalisation or not (upper or lower case) is very important. H7G6 does not exist. H7g6 does exist.

Munkul

Jack of some trades, Master of none

- Messages

- 7,892

- Location

- Cumbria

That Coban chart is really confusing.

fractory.com

fractory.com

This type of chart is what I was taught and makes far more sense, especially with the visual help at the top.

Limits & Fits | Types of Fits Explained & Tolerance Charts | Fractory

Limits and fits are a set of rules regarding the measurements and tolerances of mating machine parts to achieve the best working conditions.

fractory.com

fractory.com

This type of chart is what I was taught and makes far more sense, especially with the visual help at the top.

Kram

Member

- Messages

- 8,371

- Location

- Sussex

Ok now I understand iso fits... to admit my mistake  H7 is not +0.2mm (depending on size), it should be upto +0.01mm to +0.035mm. I was 10x out

H7 is not +0.2mm (depending on size), it should be upto +0.01mm to +0.035mm. I was 10x out

That means the first amazon set are no where near h7. However, they are still useful if you want a clearance hole, I'll still use them for that.

I'll check the H8 set when lathe is back together.

H7 is not +0.2mm (depending on size), it should be upto +0.01mm to +0.035mm. I was 10x out

H7 is not +0.2mm (depending on size), it should be upto +0.01mm to +0.035mm. I was 10x out

That means the first amazon set are no where near h7. However, they are still useful if you want a clearance hole, I'll still use them for that.

I'll check the H8 set when lathe is back together.

Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

Or get yourself one of theseCheck your tailstock alignment because that will throw a reamer out if the tailstock is out of line or ******

Cheers mateHeres the links, not available from the same seller and tbe second price has gone up. It took quite a bit of searching to find the H8 set.

www.amazon.co.uk/gp/aw/d/B07V4747BW

www.amazon.co.uk/gp/aw/d/B07VWVH8XL

123hotchef

Member

- Messages

- 14,395

- Location

- Kent

what is it?