You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Dr.Al

Forum Supporter

- Messages

- 2,773

- Location

- Gloucestershire, UK

Oiled the cutting board:

Looks lovely. What wood is that?

Nick DV

"That's the only name they ever gave me."

- Messages

- 1,733

- Location

- "A long time ago in a galaxy far, far away...."

Nice workOiled the cutting board:

Memmeddu

Member

- Messages

- 5,809

- Location

- Italia Sardegna

Went to visit the local machinist this morning .

At least they have an idea of who I am and not just a curriculum.

Presented myself , explained my reasons why I'd like to learn this job.

Explained that I currently have no experience in machining but I'd like to learn .

They asked what I'm able to do related to their job ,read and use calipers, micrometers (0.01 resolution) and dial indicators.

Stick weld little bit .

They asked if I'm able to assemble and disassemble things , I've explained that I've always had the passion to understand how things work , and that I repair power tools and small engines to make little bit of money.

They asked if I'm able to work on scooters (apparently they work on those engines too so they might be interested in someone able to complete disassemble and put things back together) , and answered that I've had some experience on my friend's ones .

They explained that because of the virus they are considering various options but they will call me if something moves.

5 minutes of my life well worth spent.

Hopefully I gave a good impression.

However it will go it's a success I believe .

At least they have an idea of who I am and not just a curriculum.

Presented myself , explained my reasons why I'd like to learn this job.

Explained that I currently have no experience in machining but I'd like to learn .

They asked what I'm able to do related to their job ,read and use calipers, micrometers (0.01 resolution) and dial indicators.

Stick weld little bit .

They asked if I'm able to assemble and disassemble things , I've explained that I've always had the passion to understand how things work , and that I repair power tools and small engines to make little bit of money.

They asked if I'm able to work on scooters (apparently they work on those engines too so they might be interested in someone able to complete disassemble and put things back together) , and answered that I've had some experience on my friend's ones .

They explained that because of the virus they are considering various options but they will call me if something moves.

5 minutes of my life well worth spent.

Hopefully I gave a good impression.

However it will go it's a success I believe .

Munkul

Jack of some trades, Master of none

- Messages

- 7,748

- Location

- Cumbria

Fingers crossed mate. Sounds like you've shown more spirit than 90% of people.Went to visit the local machinist this morning .

At least they have an idea of who I am and not just a curriculum.

Presented myself , explained my reasons why I'd like to learn this job.

Explained that I currently have no experience in machining but I'd like to learn .

They asked what I'm able to do related to their job ,read and use calipers, micrometers (0.01 resolution) and dial indicators.

Stick weld little bit .

They asked if I'm able to assemble and disassemble things , I've explained that I've always had the passion to understand how things work , and that I repair power tools and small engines to make little bit of money.

They asked if I'm able to work on scooters (apparently they work on those engines too so they might be interested in someone able to complete disassemble and put things back together) , and answered that I've had some experience on my friend's ones .

They explained that because of the virus they are considering various options but they will call me if something moves.

5 minutes of my life well worth spent.

Hopefully I gave a good impression.

However it will go it's a success I believe .

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

Just got a couple of coats of preservative on before the rain started - pics when it stops, which may be some days if you believe forecasts.

Don't put too much reliance on forecasts, it's not as bad atm, so.......

Those bits of guttering don't do anything, they're just tucked out of the way. And, yes...the shed will be getting preservative splashed on when time & weather permit.

And those bits of paving slab will be gone too, they're purpose was to weight down a tarpaulin which'll be replaced by a 'custom made' cover for the wheel stack.

And those bits of paving slab will be gone too, they're purpose was to weight down a tarpaulin which'll be replaced by a 'custom made' cover for the wheel stack.Memmeddu

Member

- Messages

- 5,809

- Location

- Italia Sardegna

Hopefully they understood that .Fingers crossed mate. Sounds like you've shown more spirit than 90% of people.

First thing once I'll get paid for other jobs done I'll buy the Italian equivalent of the machinery hand book.

800+ pages where it's explained how use an engine lathe (just the lathe)

Then another book about milling machines

Other 600+ pages .

Agroshield

Member

- Messages

- 6,342

...I'll buy the Italian equivalent of the machinery hand book.

but it is not strong on basic use of the tools. A very good one, if you can find in your language is Moltrecht's 'Machine Shop Practice' (2 volumes).

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,495

- Location

- France, Brittany.

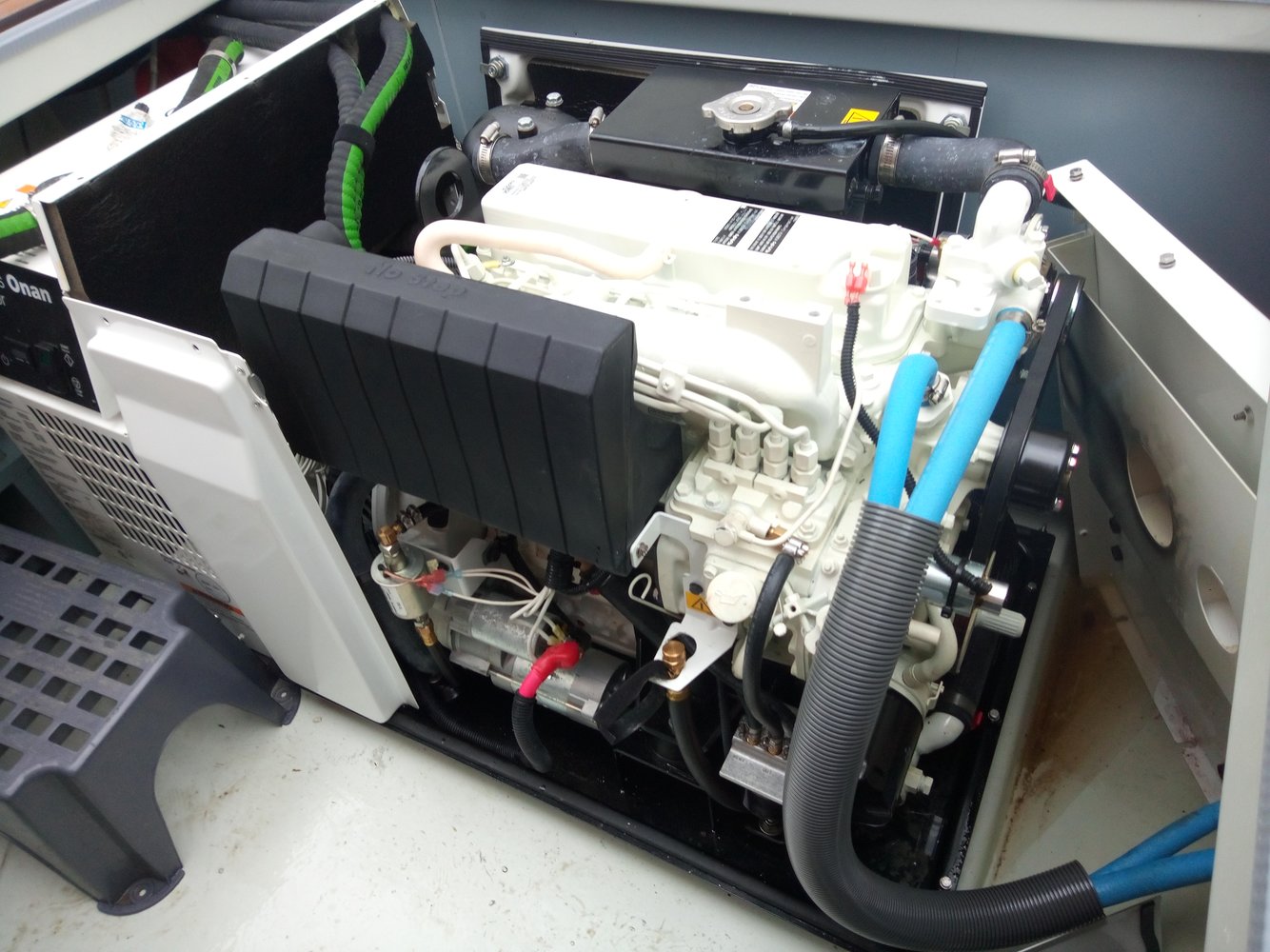

Stuff I've made today....

A Cummings Onan marine diesel generator shed some weight in covers, and spilt canal water everywhere.

Bloody thing wasn't cooling itself as it should, I'm very familiar with the four pot Kubota, but the marinisation side of it I'm not familiar with. So it got taken apart, pipes traced, and five hours later I'm still none the wiser.

Mud which has solidified in the heat exchanger is my bet, but I've never seen such a small heat exchanger before, and it seems the core doesn't come out?

Something is blocked somewhere.

PITA to work on.

Anyone any experience of these?

That's the blurry heat exchanger bottom right, grrr.

That's the blurry heat exchanger bottom right, grrr.

A Cummings Onan marine diesel generator shed some weight in covers, and spilt canal water everywhere.

Bloody thing wasn't cooling itself as it should, I'm very familiar with the four pot Kubota, but the marinisation side of it I'm not familiar with. So it got taken apart, pipes traced, and five hours later I'm still none the wiser.

Mud which has solidified in the heat exchanger is my bet, but I've never seen such a small heat exchanger before, and it seems the core doesn't come out?

Something is blocked somewhere.

PITA to work on.

Anyone any experience of these?

James1979

Member

- Messages

- 8,290

- Location

- Orkney

I was trying to cure one that was cutting out today as it happens. Do you have the manual? I am not sure how much help it will be as I was looking for the blink codes but I can ask the guy if he can send me relevant bits, assuming there are any if you want?

Yours is a slightly different layout from todays. it had a fuel pump driven water pump which was on the left of the injector pump as you look at it from the side you've photographed. cant make it out. Think its the same other then that though

Edit, your lift pump is in a slightly less stupid place. Is that a new one? This one has about 12k hours

Yours is a slightly different layout from todays. it had a fuel pump driven water pump which was on the left of the injector pump as you look at it from the side you've photographed. cant make it out. Think its the same other then that though

Edit, your lift pump is in a slightly less stupid place. Is that a new one? This one has about 12k hours

Memmeddu

Member

- Messages

- 5,809

- Location

- Italia Sardegna

Tomorrow I'll go to make a paper copy

but it is not strong on basic use of the tools. A very good one, if you can find in your language is Moltrecht's 'Machine Shop Practice' (2 volumes).

Woody.v8

Blue gluer

- Messages

- 4,213

- Location

- staffs

Almost finished refurbing my crane hook with new thrust washer collets made a new nut and a handle/locking pin made for the main pin and a new nipple for luck, still waiting on safety latch for the hook then shes ready for a lick of paint .

Also fabbed some plates for the led beacon bar, I may have got carried away

Also fabbed some plates for the led beacon bar, I may have got carried away

Memmeddu

Member

- Messages

- 5,809

- Location

- Italia Sardegna

3900+ pagesTomorrow I'll go to make a paper copy

There's not something more apprentice friendly?

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,495

- Location

- France, Brittany.

It's two years old , less than 900 hours, electric fuel pump, but the marinisation system is like none I've seen before. The coolant to raw water is the size of an oil cooler, looks like the matrix (?) can't be removed, semi traditional exhaust manifold with an expansion tank sat on top, and uuhhh, installed by Linnssen so it's not very accessible and some intriguing (stupid) installation features.I was trying to cure one that was cutting out today as it happens. Do you have the manual? I am not sure how much help it will be as I was looking for the blink codes but I can ask the guy if he can send me relevant bits, assuming there are any if you want?

Yours is a slightly different layout from todays. it had a fuel pump driven water pump which was on the left of the injector pump as you look at it from the side you've photographed. cant make it out. Think its the same other then that though

Edit, your lift pump is in a slightly less stupid place. Is that a new one? This one has about 12k hours

henry Kadzielski

Member

- Messages

- 1,209

- Location

- Australia Wollongong

Just been playing with a new toy. Got 'Electra' a couple of weeks ago for a job to remove a broken tap in s/s with a blind hole and she performed as was described on the box. So, one of my customers asked if I could drill some torx bits as the owner ordered them from China with no center hole  . They have tried drilling them with an Artu bit which heats the tip and then softens it making it useless. I came to the rescue and said that I have just the thing. An EDM will drill the hole for you without annealing the material, so 'Electra' was sent to work.

. They have tried drilling them with an Artu bit which heats the tip and then softens it making it useless. I came to the rescue and said that I have just the thing. An EDM will drill the hole for you without annealing the material, so 'Electra' was sent to work.

I was given a few to try 85, I though that was more than a few, was subsequently told they have about 1000

. May even get my money back on this job

. May even get my money back on this job

. They have tried drilling them with an Artu bit which heats the tip and then softens it making it useless. I came to the rescue and said that I have just the thing. An EDM will drill the hole for you without annealing the material, so 'Electra' was sent to work.

. They have tried drilling them with an Artu bit which heats the tip and then softens it making it useless. I came to the rescue and said that I have just the thing. An EDM will drill the hole for you without annealing the material, so 'Electra' was sent to work.I was given a few to try 85, I though that was more than a few, was subsequently told they have about 1000

. May even get my money back on this job

. May even get my money back on this job

James1979

Member

- Messages

- 8,290

- Location

- Orkney

Which brand is that?Just been playing with a new toy. Got 'Electra' a couple of weeks ago for a job to remove a broken tap in s/s with a blind hole and she performed as was described on the box. So, one of my customers asked if I could drill some torx bits as the owner ordered them from China with no center hole. They have tried drilling them with an Artu bit which heats the tip and then softens it making it useless. I came to the rescue and said that I have just the thing. An EDM will drill the hole for you without annealing the material, so 'Electra' was sent to work.

I was given a few to try 85, I though that was more than a few, was subsequently told they have about 1000. May even get my money back on this job