Ali

Member

- Messages

- 1,939

- Location

- Cheshire

@Parm is half right, I see a lot of those. I’m not qualified to design the ducting (BOHS P602) but I am to test them (P601). I’ve seen enough / failed enough systems with badly designed ductwork to know it is complicated (not to mention the hoods - just plugging the duct into the port on the back of a woodworking machine and assuming it’s going to work because the flow in the duct is theoretically adequate would be naive, that’s why you commission). I have an awful lot of respect for those who know what they’re doing and get it right.

Also ATEX provision (DSEAR regs), fire dampers between fire walls etc. etc. There’s typically 80 pages of guff like that in one of my reports.

Unfortunately there’s no such thing as a cheap system that ticks all the boxes. It probably won’t do much for the fine dust (ie., the nasty stuff), but it will pull the chips - the risk is that the operators think the big shiny system is protecting them, really it’s just keeping things a bit tidier in the workshop.

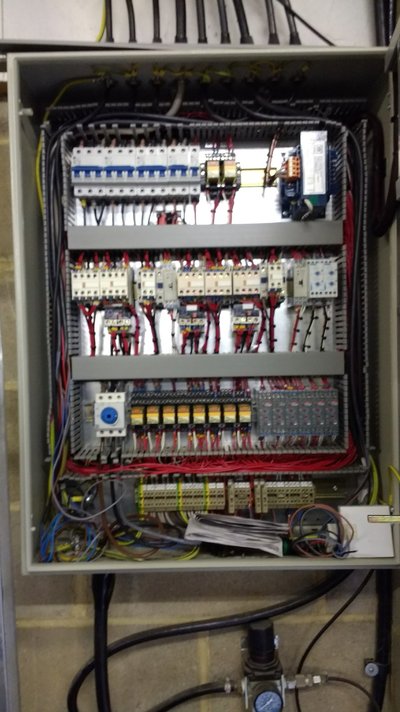

The electrical part shouldn’t be complicated for an electrician with experience of that sort of kit.

The timer is for the duration of the shaker run, depends on the system application / filter media. They’re horribly noisy with those big units, just bolted together steel panels - I carry a dB meter and can’t remember letting one like that go without an advisory.

Work is work at the moment I suppose, no point being negative but I suppose it wouldn’t hurt to pass on the advice here to the employer in case he/she isn’t aware of their responsibilities and the ramifications of getting it wrong.

I certainly wouldn’t sign anything to say it works even if it appears to!

Also ATEX provision (DSEAR regs), fire dampers between fire walls etc. etc. There’s typically 80 pages of guff like that in one of my reports.

Unfortunately there’s no such thing as a cheap system that ticks all the boxes. It probably won’t do much for the fine dust (ie., the nasty stuff), but it will pull the chips - the risk is that the operators think the big shiny system is protecting them, really it’s just keeping things a bit tidier in the workshop.

The electrical part shouldn’t be complicated for an electrician with experience of that sort of kit.

The timer is for the duration of the shaker run, depends on the system application / filter media. They’re horribly noisy with those big units, just bolted together steel panels - I carry a dB meter and can’t remember letting one like that go without an advisory.

Work is work at the moment I suppose, no point being negative but I suppose it wouldn’t hurt to pass on the advice here to the employer in case he/she isn’t aware of their responsibilities and the ramifications of getting it wrong.

I certainly wouldn’t sign anything to say it works even if it appears to!

appears, to put a stop to the acrimony generated by this thread.

appears, to put a stop to the acrimony generated by this thread.

Oh deary deary me .

Oh deary deary me .