RobCox

Member

- Messages

- 547

- Location

- Cambridge, UK

Thanks Pete. I was very pleasantly surprised how nicely the table performs after scraping. Maybe one day I'll get round to correcting the wear on my mill knee, if I'm feeling brave.

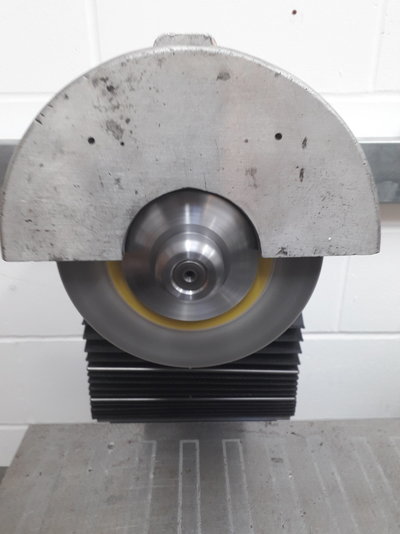

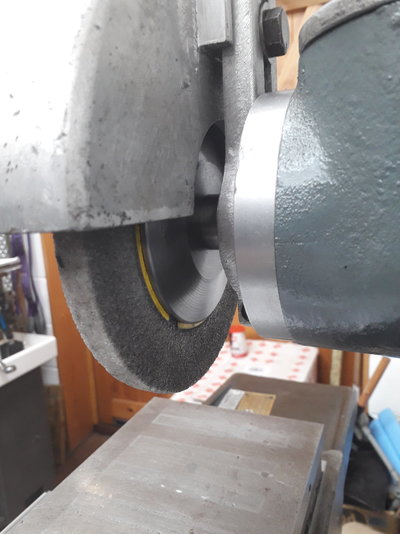

The nut that secures the wheel on shouldn't affect the preload on my spindle bearings. The preload is applied with a wave washer at the rear and a sort of piston arrangement presses on this washer and is adjusted with a bolt at the back. One of the earlier posts has a picture of the assembly. I replaced the bearings on mine as the rollers and centre parts were a tad rough.

The nut that secures the wheel on shouldn't affect the preload on my spindle bearings. The preload is applied with a wave washer at the rear and a sort of piston arrangement presses on this washer and is adjusted with a bolt at the back. One of the earlier posts has a picture of the assembly. I replaced the bearings on mine as the rollers and centre parts were a tad rough.

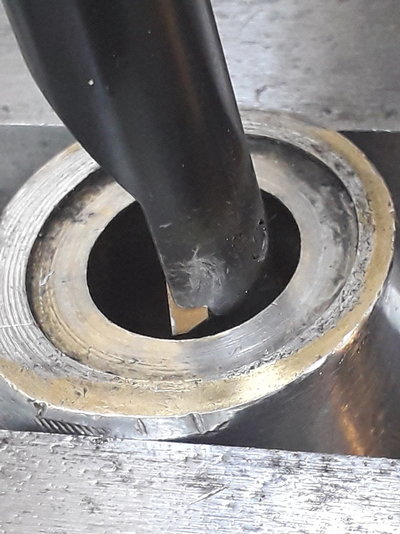

! So I cleaned it up, clamped it together and silver brazed it, which worked really well

! So I cleaned it up, clamped it together and silver brazed it, which worked really well

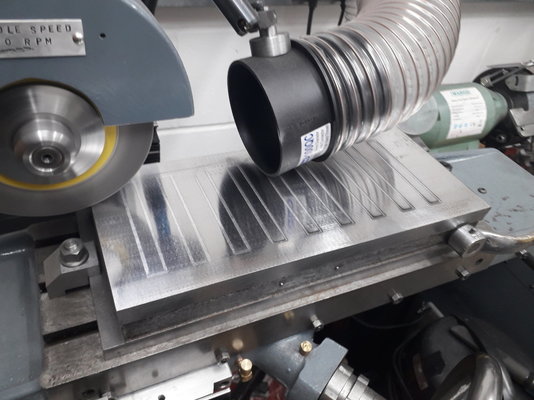

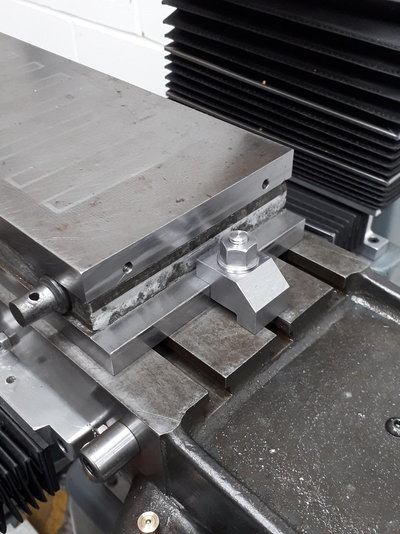

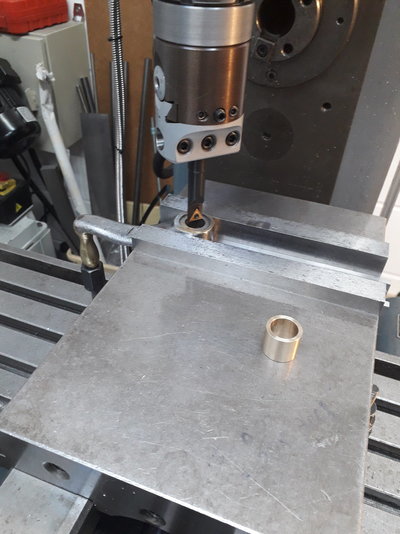

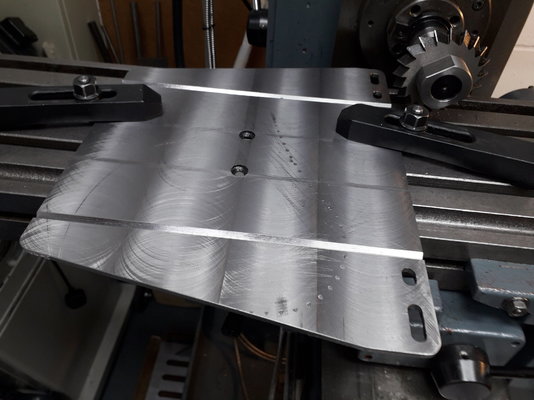

! In case you're wondering, the full travel is needed to grind the mag chuck, which badly needed attention as my initial efforts revealed it wasn't grinding "perfectly" flat, but was a few thou out. The cause of this third table/knee problem was the misalignment of the leadscrew as I'd fitted a long bushing in the knee which didn't allow for any play. I ended up curing it by milling 20 thou off the bottom of the nut casting and shimming it for a nice fit:

! In case you're wondering, the full travel is needed to grind the mag chuck, which badly needed attention as my initial efforts revealed it wasn't grinding "perfectly" flat, but was a few thou out. The cause of this third table/knee problem was the misalignment of the leadscrew as I'd fitted a long bushing in the knee which didn't allow for any play. I ended up curing it by milling 20 thou off the bottom of the nut casting and shimming it for a nice fit: